Copper Alloy Forging: Processes, Types & Applications

In modern industry, copper alloy forging plays an indispensable role across a wide range of sectors. From precision watch components to massive ship propellers, from connectors in electronic and electrical equipment to critical aerospace parts, copper alloy forging provides a solid foundation for manufacturing products that demand both performance and reliability. This article delves into the process characteristics, classification, and diverse applications of copper alloy forging, offering a thorough understanding of this vital metalworking technology.

Process Characteristics of Copper Alloy Forging

Copper alloy forging is a metalworking method in which a copper alloy is heated to a specific temperature and then plastically deformed under external force to achieve the desired shape and size of a component or blank. Copper alloys are widely used in forging due to their excellent corrosion resistance, electrical and thermal conductivity, and adequate strength. Beyond shaping capabilities, forging improves the material’s microstructure, enhances mechanical properties, and enables the production of complex parts to meet the precision and performance requirements of various industries.

1. Shrinkage Characteristics

Most copper alloys exhibit significant shrinkage during solidification, especially aluminum bronze. Improper control of shrinkage can lead to internal defects such as shrink holes or porosity, compromising the quality and performance of the forged part. Therefore, mold design and gating systems must carefully account for the alloy’s shrinkage characteristics, ensuring appropriate riser, gate, and cavity dimensions. This allows the molten metal to fully fill the mold and receive sufficient feed during solidification.

2. Oxidation and Flux Usage

Copper alloys are highly prone to oxidation in the molten state, and the resulting oxides can dissolve in the metal, reducing mechanical performance. To prevent oxidation, fluxes such as glass or borax are commonly added when melting bronze. These fluxes form a protective layer on the molten metal’s surface, isolating it from air and minimizing oxidation. For example, adding borax when melting tin bronze effectively preserves metal purity and enhances casting quality.

3. Cooling Rate and Solidification Control

Cooling rate significantly influences the microstructure and performance of copper alloy castings. Tin bronze, when forged in metal molds, benefits from rapid cooling, producing narrow solidification zones that minimize porosity and yield dense internal structures. Lead bronze, prone to segregation, requires careful control of pouring temperature and thorough pre-pouring stirring to homogenize the melt. Rapid cooling and controlled solidification sequences help prevent shrinkage defects, ensuring high-quality castings.

4. Gating System Design

A well-designed gating system is crucial in copper alloy forging. Bottom-pour systems are often preferred as they allow smooth metal flow into the mold cavity, reducing splashing and air entrapment, and minimizing oxide inclusions. Proper gating ensures uniform metal flow, complete cavity filling, and the production of parts with accurate dimensions and superior surface quality.

Classification and Characteristics of Copper Alloys

Understanding copper alloy types and their characteristics is essential, as they determine the material’s suitability for different applications and influence specific forging considerations.

1. Forged Brass

Forged brass is divided into common brass and specialty brass.

- Common Brass: Common brass is a binary alloy of copper and zinc. With 30–40% zinc content, it achieves good mechanical properties, surpassing tin bronze in strength and plasticity. It exhibits excellent machinability, wear resistance, and corrosion resistance, making it suitable for general corrosion-resistant components such as valves, fittings, small hardware, and mechanical parts. Zinc also acts as a natural deoxidizer, eliminating the need for additional flux during melting and simplifying production.

- Specialty Brass: Specialty brass adds small amounts of other elements, such as aluminum, manganese, or silicon, to common brass, forming multi-component alloys. These additions enhance strength, hardness, and chemical resistance while maintaining good machinability. Aluminum brass, for instance, offers high strength and corrosion resistance, often used in ship components and condensers; manganese brass provides wear and corrosion resistance, suitable for high-load mechanical parts.

2. Forged Bronze

Forged bronze mainly includes tin bronze and special bronzes.

- Tin Bronze: Tin bronze contains 3–14% tin, often with phosphorus, zinc, or lead. It demonstrates excellent corrosion resistance in air, freshwater, seawater, and steam, making it ideal for steam boilers, marine components, elastic parts, and wear-resistant components. Phosphor tin bronze offers good mechanical properties for high-precision machine parts; leaded tin bronze is used for bearings and wear parts; zinced tin bronze can produce components requiring high airtightness. Tin bronze, however, has a wide crystallization range and poor fluidity, making micro-porosity common and forging relatively challenging.

- Special Bronze: Special bronzes replace tin with other elements. Lead bronze, for example, has excellent corrosion resistance in acidic and alkaline environments and is used for gears, worm gears, and ship propellers under heavy loads. Aluminum bronze offers a cost advantage of 20–25% over tin bronze but has drawbacks such as higher dry friction, poor thermal conductivity, and limited resistance to high-temperature steam erosion, preventing full replacement of tin bronze.

3. Nickel Silver (Cu-Ni Alloys)

Nickel silver, a copper-based alloy with nickel as the main additive, combines excellent mechanical properties, corrosion resistance, aesthetic appeal, and deep-drawing performance. Applications include shipbuilding, petrochemicals, electrical components, instruments, medical devices, daily-use products, and decorative items. Complex nickel silvers include additions of manganese, iron, zinc, or aluminum. For example:

Iron nickel silver (Fe < 2%) offers high strength and corrosion resistance, used in heat exchangers and marine forgings.

Manganese nickel silver exhibits low temperature coefficient of resistance and excellent corrosion resistance.

Zinc nickel silver combines good mechanical performance, corrosion resistance, formability, and machinability.

Aluminum nickel silver (optimal Ni:Al = 10:1) is widely used in electrical, shipbuilding, and chemical industries for high-strength, corrosion-resistant components.

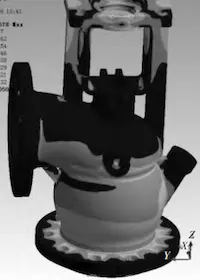

Applications of Copper Alloy Forging

Copper alloy forging’s versatility and performance make it valuable across multiple industries.

- Mechanical Manufacturing: Copper alloy forgings are widely used in mechanical components. Brass, with good machinability and wear resistance, is used in valves, fittings, and hardware; specialty brass serves in ship parts, condensers, and corrosion-resistant components. Tin bronze produces wear-resistant and elastic components for high-precision machine tools, boilers, and marine applications. These forgings combine mechanical strength and corrosion resistance, enhancing equipment reliability and lifespan.

- Electronics and Electrical: Copper alloys’ excellent electrical and thermal conductivity makes them ideal for electronic and electrical applications, including connectors and heat exchangers. Forged copper alloy connectors ensure stable current transmission, while heat exchangers efficiently dissipate heat, maintaining device performance and prolonging service life.

- Aerospace: In aerospace, copper alloy forgings are used in high-stress and corrosive environments for engine components, hydraulic systems, and other critical parts. Their high strength, toughness, and corrosion resistance ensure reliable operation under extreme temperatures, pressures, and speeds.

- Marine and Offshore: Marine and offshore equipment require strong corrosion resistance. Forged copper alloy components like ship propellers, gears, and worm wheels withstand seawater exposure while maintaining mechanical integrity. For instance, lead bronze propellers offer high strength and resistance to long-term sea exposure and operational thrust.

- Architecture: Copper alloy forgings are used in building decorative and functional components such as door and window fittings, railings, trims, faucets, and plumbing parts. They combine aesthetics, durability, corrosion resistance, and sealing performance, ensuring both longevity and functionality in buildings.

Process Parameter Control in Copper Alloy Forging

To ensure the quality and performance of forged copper components, controlling process parameters is critical. Key parameters include forging ratio, heating temperature, holding time, initial and final forging temperatures, deformation amount, and deformation speed.

1. Forging Ratio

The forging ratio indicates the degree of metal deformation, directly affecting microstructure and performance. Higher ratios refine grains and improve strength and toughness, whereas lower ratios prevent excessive deformation and cracking in complex parts.

2. Heating Temperature and Holding Time

Proper heating ensures adequate plasticity. Excessive temperature enlarges grains, reducing performance; insufficient temperature reduces ductility, causing defects. Holding time ensures uniform temperature distribution to prevent forging issues.

3. Initial and Final Forging Temperatures

Both initial and final forging temperatures are critical. Incorrect temperatures can result in grain growth, cracking, or reduced mechanical properties. Maintaining optimal temperature ranges ensures smooth forging and high-quality parts.

4. Deformation Amount and Speed

The degree and speed of deformation influence metal flow, microstructure, and defect formation. Proper deformation enhances properties, while incorrect parameters can cause cracks or uneven structures.

Conclusion

Copper alloy forging, with its unique material properties and wide application range, holds a vital role in modern industry. Understanding its process characteristics, classifications, applications, and precise control of forging parameters enables manufacturers to maximize product quality, reduce costs, and enhance industrial performance. By keeping pace with technological advancements and exploring innovative processes, copper alloy forging will continue to evolve, playing an increasingly important role in future industrial development.

Send your message to this supplier

Related Articles from the Supplier

Forging and Annealing Processes of Copper Alloys

- Oct 30, 2024

Copper Alloy Casting Processes and Properties

- Dec 26, 2024

Cast Copper Alloy Corrosion and Mechanisms

- Jan 03, 2025

Related Articles from China Manufacturers

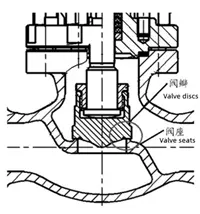

New Copper Alloy Valves for Ships

- Sep 20, 2024

Causes of Failures of Copper Alloy Globe Valve Seals

- Aug 25, 2022

Introduction to Copper Ball Valves

- Aug 29, 2024

Copper Forging Processes and Heat Treatment

- Jan 14, 2026

International Copper Grades Table

- Oct 27, 2016

Related Products Mentioned in the Article

Supplier Website

Source: https://www.forging-casting-stamping.com/copper-alloy-forging-processes-types-applications.html