Packing Installation for Reliable Valve Sealing

Valves, as essential components in industrial systems, have sealing performance that directly affects the stability and safety of the entire production process. Packing, being a key sealing element of a valve, requires correct selection and installation, which not only impacts the valve's sealing effectiveness but also directly determines its service life and maintenance costs. This article will provide a detailed explanation of the packing installation steps, key considerations, and the characteristics of different packing materials, offering comprehensive and practical technical guidance to help you better understand and master this critical technique, ensuring your industrial systems operate safely and efficiently.

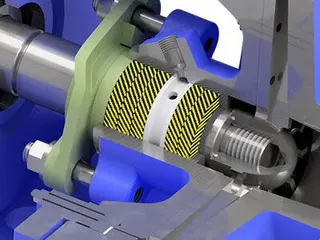

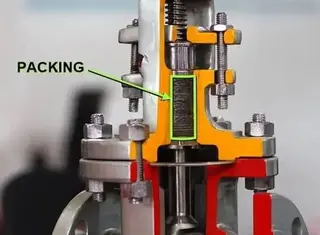

Basic Structure and Function of Packing

Packing is usually installed in the valve stuffing box to seal the gap between the valve stem and the valve body, preventing medium leakage. A typical stuffing box can accommodate four to six packing rings, and the number of sealing elements on the valve stem depends on the specific structure, sometimes only one or two, and in rising-stem structures, there may be seven packing rings. The main manufacturing methods of packing rings are braiding and molded forming.

Braided packing materials can be cut into segments according to the circumference of the mandrel or valve stem, with the cut usually at 45º (angled) or 90º (perpendicular). Angled cuts are recommended because they provide better end-face contact under axial load. Each packing ring must completely surround the entire circumference of the mandrel or valve stem, and the tightness between the outer side of the packing ring and the stuffing box wall should be higher than that between the inner side of the packing ring and the valve stem. If the cut ends of the packing rope are too long or too short, it will lead to uneven density in the packing ring, forming potential leakage paths.

Correct Steps for Packing Installation

The correct installation method is key to ensuring valve sealing performance, which directly relates to valve reliability and safety. Therefore, mastering the correct installation steps is essential.

1. Preparation

Before installing packing, a comprehensive hazard and risk assessment must be conducted to ensure construction safety. First, properly isolate the valve to prevent medium leakage from causing danger. Operators should wear protective clothing and goggles as required to ensure personal safety.

Next, use packing removal tools to clean out all old packing from the stuffing box. Carefully inspect the valve stem for pitting and scratches, and ensure that all old packing has been completely removed. If the valve stem is damaged, refurbishment is necessary.

Then, measure the valve stem outer diameter, stuffing box inner diameter, and stuffing box cavity depth to accurately calculate the packing size. The packing ring radius can be calculated by the formula (OD − ID)/2, where OD is the stuffing box inner diameter and ID is the valve stem outer diameter. Then, calculate the number of packing ring layers needed based on the stuffing box cavity depth.

2. Cutting and Processing Packing Material

Packing material can be wrapped around a mandrel of the same diameter as the valve stem and cut vertically (radially), or cut at an angle using specialized packing tools. During cutting, care must be taken to avoid stretching the packing along its length and to prevent cross-sectional deformation due to compression. It is also important that the cut surface is neat and clean, with no impurities or debris.

The stuffing box must not be filled by winding the packing material; instead, use special cutting tools to cut braided packing into independent rings with 45º angled cuts, so that the load can achieve better end-face contact. Check whether each packing ring fits exactly into the stuffing box; the interface of each ring should be properly joined, and the outer ring should fit tightly against the stuffing box wall. It is not allowed to stretch the braided material to match the inner diameter. All subsequently installed packing rings must have the same size and cutting method as the first one.

Preformed molded packing rings are very common and do not require on-site cutting, making them easy to install. First, inspect the valve bonnet bolts, nuts, and gaskets, and replace any that are damaged. Bolts and nuts should be greased to prevent rust and facilitate disassembly.

3. Installing Packing Rings

To effectively control fugitive leakage, a torque wrench must be used, and the operating procedures provided by the packing supplier must be followed. The stuffing box must also be clean and free of debris and oil. Place the first packing ring into the stuffing box, paying attention to the position of the cut, inserting the cut part first, then the rest of the ring. For flexible graphite molded packing rings, each ring should be stretched into a spiral before installation to avoid damage.

Install one packing ring at a time, ensuring it is seated and pressed properly before installing the next. If the gland follower is not long enough to reach the bottom of the stuffing box, temporary tools or extension rings are required for installation. Unless specifically stated, sealing elements must not be lubricated. Apply the load to the first installed packing ring according to the manufacturer's operating specifications. Repeat the same steps for each additional ring, installing one ring at a time. The interfaces of any two adjacent packing rings must be positioned separately at 90º and 180º.

After installation, operate the valve stem through three to ten open-close cycles to ensure the packing set is properly seated. During this process, the packing set will relax to some extent, so after completing the open-close operation, re-tighten according to the manufacturer's parameters to provide sufficient margin for future relaxation. Similarly, after the valve is put into normal operation, perform a final tightening of the packing set to reserve sufficient margin for stress relaxation.

Selection of Packing Material

The performance of packing and sealing materials can only reach optimal levels within specific temperature ranges. For example, PTFE has a temperature range of approximately −101°C to 232°C. If applied in higher temperature environments, its molecular structure may change, leading to the leakage of harmful gases, corrosion of the valve stem, or even the release of toxic PTFE fumes from the top of the gland follower. Such fumes may even be carcinogenic. Additionally, as fumes are released, the packing material will soften, lose weight, and result in leakage of hazardous process media or product.

Flexible graphite has a different applicable temperature range. In an oxidizing atmosphere, it is generally −196°C to 450°C. Considering material characteristics such as ash content, chlorides, sulfur, fluorides, and other halogen compounds, as well as the manufacturer's provided oxidation loss data, graphite packing can reliably prevent fugitive leakage up to 450°C, and in non-oxidizing vapor conditions, it can withstand up to 650°C.

Both flexible graphite and PTFE are widely suitable for media with pH 0–14; graphite is also applicable in some cases for fire-safe sealing.

Consequences of Improper Installation

If a set of five packing rings is installed at once, the top ring closest to the gland follower bears the highest load, while the bottom ring closest to the process medium bears very little, sometimes negligible load. As a result, the bottom packing ring's ability to prevent medium leakage is reduced, regardless of whether it is braided or molded. Another situation is applying excessive load on the top ring, which can lead to excessive friction when rotating the stem, or even damage the packing set.

Importance of Correct Packing Installation

If packing is installed correctly, the decay from axial stress to radial stress is reduced. This helps the packing maintain reliable sealing performance for a longer period and achieve reasonable friction load distribution. On this basis, the valve's fugitive leakage sealing performance and production efficiency will significantly improve.

However, today, government regulations aim to eliminate leakage, with regulatory requirements and standards to detect, reduce, and control fugitive valve leakage. Additionally, manufacturers and end users require valves to pass various standard tests such as ISO 15848-1, API 624, and API 641.

Correct packing installation procedures are one of the factors determining whether sealing performance is qualified. Sealing performance is an important indicator of whether a valve supplier's value exceeds that of competitors.

Conclusion

The installation of packing is a process that requires careful handling and strict adherence to standards. From selecting the appropriate packing material to correctly cutting and installing the packing rings, every step is crucial. Proper installation not only extends the service life of the packing but also significantly enhances the valve's sealing performance, reduces the risk of leakage, and ensures smooth industrial operations. This article aims to help you better understand and master the key techniques of packing installation, ensuring that your valves operate reliably under various working conditions.

Send your message to this supplier

Related Articles from the Supplier

Packing Installation for Reliable Valve Sealing

- Sep 26, 2025

Related Articles from China Manufacturers

Installation and Maintenance of Packing Seals

- Feb 04, 2026

Installation and Maintenance of Graphite Packing

- Nov 21, 2025

Related Products Mentioned in the Article

Supplier Website

Source: https://www.bossealvalves.com/news/packing-installation-for-reliable-valve-sealing.html