Major Differences between Diaphragm Valves and Globe Valves

In the industrial world, valves are indispensable components of piping systems, acting like gatekeepers that precisely control the flow of fluids. Among the many valve types available, diaphragm valves and globe valves stand out as two of the most commonly used, each with its own unique structure, performance characteristics, and application scenarios. In this article, we take an in-depth look at the differences between these two diaphragm valves and globe valves to help you make a more informed decision when selecting the right valve for your application.

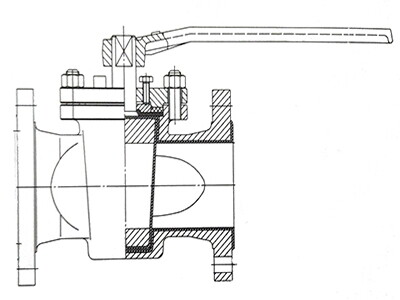

Overview of Globe Valves

Globe valves are one of the oldest and most widely used types of valves. Their closing element (the disc) moves along the centerline of the valve seat, and the change in the seat opening is directly proportional to the disc travel. In simple terms, when a globe valve is operated, the up-and-down movement of the disc directly changes the size of the flow passage, enabling precise control of fluid flow.

1. Structure and Working Principle of Globe Valves

The structure of a globe valve is relatively simple, mainly consisting of a valve body, disc, stem, and bonnet. The disc is plug-shaped, and the sealing surface can be flat or conical. There are two common stem movement designs:

- Rising stem (non-rotating stem): the stem moves up and down while the handwheel remains stationary.

- Rising and rotating stem: the stem and handwheel rotate and move up and down together, with the nut located in the valve body.

When the medium enters the valve chamber from below the disc, the operating force must overcome both the friction between the stem and packing and the thrust generated by the medium pressure. As a result, the force required to close the valve is greater than that required to open it, which necessitates a sufficiently large stem diameter to prevent bending.

2. Advantages of Globe Valves

- Reliable shut-off performance: Globe valves have a relatively short opening and closing stroke, enabling rapid shut-off and making them ideal for applications requiring frequent operation.

- Excellent throttling capability: Because the change in seat opening is proportional to disc travel, globe valves provide highly accurate flow regulation, making them suitable for systems with strict flow control requirements.

- Good wear resistance: During opening and closing, the friction between the disc and the seat is lower than that of gate valves, resulting in better wear resistance and a longer service life.

- High temperature resistance: The packing of globe valves is typically made of a mixture of asbestos and graphite, allowing them to withstand high temperatures. For this reason, globe valves are commonly used in steam systems.

- Easy maintenance: Globe valves usually have only one sealing surface between the body and disc, which simplifies manufacturing and makes maintenance and part replacement more convenient.

3. Disadvantages of Globe Valves

- High flow resistance: The change in flow direction through the valve results in higher minimum flow resistance compared to many other valve types, which can affect system pressure.

- Slower opening speed: Due to the relatively long stroke, globe valves open more slowly than quick-acting valves such as ball valves.

- Restricted flow direction: The medium typically flows into the valve chamber from above the disc, which can limit its use in certain applications.

4. Applications of Globe Valves

Globe valves are used across a wide range of conditions, from vacuum systems to high-temperature and high-pressure environments. They are commonly found in steam systems, water treatment facilities, and petrochemical plants, especially where precise flow control and frequent opening and closing are required.

What are Diaphragm Valves?

Diaphragm valves are a relatively newer type of valve. Their defining feature is a flexible diaphragm or composite diaphragm installed inside the valve body and bonnet, with the closing element being a compression device connected to the diaphragm. This design allows diaphragm valves to perform exceptionally well when handling corrosive media or fluids containing suspended particles, which has led to their widespread adoption in recent years.

1. Structure and Working Principle of Diaphragm Valves

The structure of a diaphragm valve is relatively simple, consisting mainly of three components: the valve body, the diaphragm, and the bonnet assembly. The diaphragm is usually made of synthetic rubber and is connected to the stem. When the valve is closed, the diaphragm is pressed against a metal weir (part of the valve body) to achieve sealing.

The valve seat may be of a weir type or a straight-through channel formed by the pipe wall. Thanks to the diaphragm, the operating mechanism is completely isolated from the flow path. This not only ensures the purity of the working medium but also prevents the medium from impacting the operating components.

2. Advantages of Diaphragm Valves

- High medium purity: The separation of the operating mechanism from the flow path ensures the purity of the medium, making diaphragm valves ideal for applications with stringent cleanliness requirements.

- Wide applicability: With various diaphragm and body materials available, diaphragm valves can effectively control a wide range of media, especially those that are chemically corrosive or contain suspended solids.

- Easy maintenance: Diaphragm valves feature a simple structure that allows for quick disassembly and maintenance. Diaphragm replacement can be performed on-site in a short time, significantly reducing maintenance time and costs.

- No leakage risk: Diaphragm valves do not require separate packing seals, except when used as safety devices for hazardous media. Since the medium only contacts the diaphragm and valve body, there is no risk of packing leakage.

3. Disadvantages of Diaphragm Valves

- Limited pressure and temperature resistance: Due to limitations in lining and diaphragm manufacturing processes, diaphragm valves have relatively low pressure and temperature ratings, generally not exceeding 180 °C. They are not suitable for high-temperature or high-pressure applications.

- Poor throttling performance: The flow regulation capability of diaphragm valves is limited and typically effective only within a small range (generally from fully closed to about two-thirds open).

- Limited pipe size range: Manufacturing large valve body linings and diaphragms is challenging, so diaphragm valves are generally used for pipelines with DN ≤ 200 mm.

4. Applications of Diaphragm Valves

Diaphragm valves are widely used in industries such as chemical processing, pharmaceuticals, food processing, and water treatment. They are particularly suitable for handling corrosive, viscous, or particle-laden fluids, such as acid and alkali solutions in chemical plants or liquid transfer in pharmaceutical production. They are also commonly used in municipal water supply, agricultural irrigation, and water supply systems for high-rise buildings.

Comparison Between Diaphragm Valves and Globe Valves

After gaining a comprehensive understanding of the structure, performance, advantages, disadvantages, and applications of both valve types, we can now compare them more directly to highlight their key differences and guide practical selection.

1. Structural Comparison

Globe Valve: Relatively complex structure consisting of a body, disc, stem, and bonnet. The disc moves along the centerline of the seat, and the seat opening changes proportionally with disc travel.

Diaphragm Valve: Simple structure consisting of a body, diaphragm, and bonnet assembly. The diaphragm is connected to the stem and opens or closes the valve through a compression mechanism.

2. Performance Comparison

|

Feature |

Globe Valve |

Diaphragm Valve |

|

Shut-off performance |

Very reliable, suitable for frequent operation |

Reliable, but generally inferior to globe valves |

|

Throttling performance |

Excellent, suitable for precise flow control |

Limited, effective only within a small range |

|

Wear resistance |

Good |

Moderate |

|

Temperature resistance |

High, suitable for high-temperature environments |

Low, generally ≤ 180 °C |

|

Flow resistance |

Relatively high |

Relatively low |

|

Maintenance |

Convenient |

Very convenient, diaphragm easy to replace |

|

Applicable media |

Wide range, including high-temperature and high-pressure media |

Corrosive, viscous, or particle-laden media |

|

Applicable pipe size |

Suitable for a wide range of diameters |

Generally DN ≤ 200 mm |

3. Application Comparison

Globe valves: Ideal for applications requiring precise flow control and frequent operation, such as steam systems, water treatment systems, and petrochemical processes.

Diaphragm valves: Best suited for handling corrosive, viscous, or particle-containing media, such as acid and alkali solutions in chemical plants, pharmaceutical fluid transfer, and municipal water supply systems.

Selecting the Right Valve

When choosing between a diaphragm valve and a globe valve, the following factors should be considered:

- Medium characteristics: Corrosive or particle-laden media favor diaphragm valves, while applications requiring precise flow control are better served by globe valves.

- Temperature and pressure: Globe valves are suitable for high-temperature and high-pressure conditions, whereas diaphragm valves are intended for lower pressures and moderate temperatures.

- Pipe size: Globe valves are more suitable for larger diameters, while diaphragm valves are a good option for pipelines with DN ≤ 200 mm.

- Maintenance requirements: If rapid maintenance and component replacement are important, the simple structure of diaphragm valves offers a clear advantage.

- Flow control needs: For systems requiring precise and stable flow regulation, the superior throttling performance of globe valves is a key benefit.

Conclusion

Both diaphragm valves and globe valves are essential components in industrial valve systems, each offering distinct advantages and limitations for different operating conditions. Globe valves excel in applications requiring reliable shut-off, precise flow control, and high temperature resistance. Diaphragm valves, on the other hand, stand out for their high media purity, broad material compatibility, and ease of maintenance, making them ideal for corrosive or particle-laden fluids.

Ultimately, selecting the right valve depends on a careful evaluation of the specific operating conditions and application requirements. We hope this article helps you better understand the differences between diaphragm valves and globe valves and provides valuable guidance for choosing the most suitable valve for your industrial projects. If you have any further questions or need additional assistance, please feel free to contact us.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.bossealvalves.com/news/major-differences-between-diaphragm-valves-and-globe-valves.html