BS 1873 Cryogenic Globe Valve, ASTM A351 CF8, DN65, PN40, BW

Product Name: BS 1873 Cryogenic Globe Valve, Extended Bonnet

Design Standard: BS 1873

Body Material: ASTM A351 CF8

Size: DN65, 2-1/2 Inch

Pressure: PN40, Class 300 LB

End Connection: BW

Operation: Handwheel

Medium: LNG, LO2, LN2, LAr, CO2

Temperature Range: -196°C to 80°C

The Cryogenic Globe Valve is specifically engineered to handle low temperatures and cryogenic conditions. Constructed from robust materials such as stainless steel, carbon steel, cast steel, and more, it is designed to withstand extreme environments. The valve features an extended bonnet, the length of which is tailored to the specific application and user requirements. This extended bonnet ensures that the stem packing is sufficiently distanced from the cryogenic fluid, thereby enhancing safety and performance. Cryogenic Globe Valves are widely used in gas/terminal production plants, ethylene plants, and LNG (liquefied natural gas) facilities. They are also ideal for throttling cryogenic fluids with temperatures as low as -196°C. We offer a range of high-performance globe valves to meet various application needs.

Technical Specifications

» Type: Cryogenic Globe Valve

» Nominal Diameter: DN65-DN100

» Design Pressure: PN40

» Material: ASTM A351 CF8, CF8M, CF3, CF3M, etc.

» Design and Manufacturing Standards: BS 1873

» Face-to-Face Standards: ASME B16.10

» Flange Dimension Standards: ASME B16.5

» Pressure Test Standards: API 598

» NACE Compliance: NACE MR 0103, NACE MR 0175

» Operator Options: Handwheel

» Process Connection Types: Butt Weld

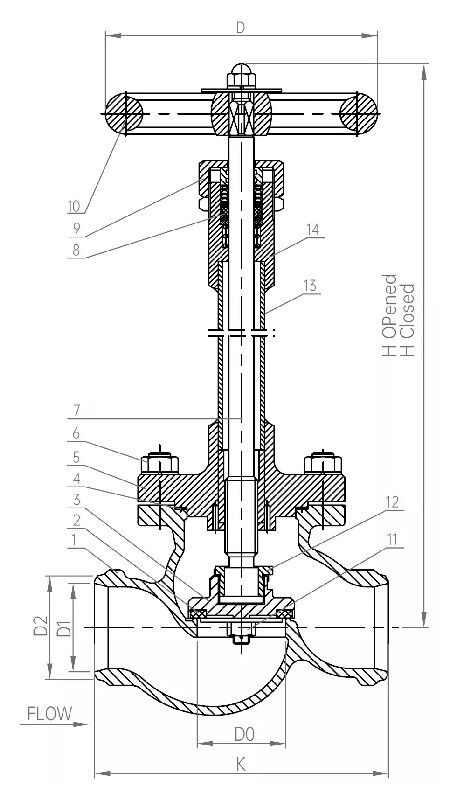

Structural Diagram

Send your message to this supplier

Related Articles from the Supplier

Use Of Globe Valve

- Dec 14, 2024

Forged Steel Globe Valve

- Dec 14, 2024

What Kinds Of Common Globe Valves Are There

- Dec 14, 2024

Selection and Application of Globe Valves

- Nov 13, 2025

Globe Valves vs. Diaphragm Valves: How to Choose?

- Sep 09, 2025

Related Articles from China Manufacturers

LNG Cryogenic Butterfly Valves

- Aug 26, 2022

The Differences Between Ball Valves and Globe Valves

- May 10, 2019

Industrial valve and pipe installation instructions

- Oct 13, 2019

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Address: Dongou Industrial Zone, Oubei, Wenzhou, Zhejiang, China

- Phone: 86 577 5798 7171

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/bs-1873-cryogenic-globe-valve-astm-a351-cf8-dn65-pn40-bw.html