Blind flange Threaded flange Welding flange Sleep on flange Weld neck flange

Blind flange (also known as a blind plate) is a type of flange without holes in the middle, specifically designed to block pipeline ends or equipment interfaces, providing a removable sealing solution. Its core advantages include welding-free installation (quickly locked with bolts and matching flanges) and flexible opening and closing. It is widely used in pipeline terminal sealing, valve isolation, and temporary blind blocking scenarios in the petrochemical and power systems, ensuring zero leakage of medium and operational safety.

Threaded flanges are a type of pipe connection that facilitates rapid installation through precise internal threads. Their weld-free design significantly reduces construction thresholds and costs, making them particularly suitable for low-pressure applications where welding is limited or frequent maintenance is required. Core advantages include convenient disassembly and assembly, compatibility with difficult-to-weld materials, and minimal additional stress on the pipeline. Widely used in lightweight pipe connections with limited space, such as petrochemical instrument piping, building fire protection, and air conditioning water systems, they offer a safe and efficient non-welding solution.

Welding flange is a type of flange with a hub that is connected to the pipeline through a transition section of a round tube via butt welding. Its high-hub structure keeps the weld joint away from the sealing surface, preventing welding deformation and ensuring sealing reliability. It is suitable for harsh working conditions with high temperature, high pressure, low temperature, or large fluctuations in pressure and temperature, such as high-temperature pipelines in petrochemical industries, liquefied natural gas transmission, and pipelines for flammable and explosive media. With advantages such as strong rigidity, resistance to deformation, and good sealing performance, it is widely used in industrial pipeline systems that require long-term safe operation.

SO flange is made of high-quality materials such as carbon steel, stainless steel, and alloy steel. It is connected to the pipeline using a flat fillet weld, featuring simple structure, convenient installation, and economical cost. Through advanced technology, the precision of the sealing surface is ensured, and it exhibits good pressure resistance and corrosion resistance. It is widely suitable for medium and low-pressure pipeline systems in water supply and drainage, heating and ventilation, and chemical industries. It can achieve reliable connections and quick disassembly between pipelines, meeting diverse engineering needs.

Weld Neck Flange (WN), Long Welding Neck Flange (LWN), Lap Joint Flange (LJ), Blind Flange / Blank Flange (BL), Slip On Flange (SO), Thread Flange (THR), Socket Weld Flange (SW), Reducing Flange, Orifice Flange, Anchor Flange, Spectacle Blind Flange (Figue 8), Spacer Ring/Spade Flange etc…

Flange Standards:

ANSI/ASME Standard: ANSI B16.5, ANSI B16.47 Series A & B, MSS-SP-44, API 605, API6A in class 150 to 2500;

AWWA C207 flanges in Class B, Class D, Class E, Class F, Ring, Blind & Hub;

European DIN, UNI, EN 1092-1, BS 4504, ISO, NS, NFE29203 flanges in Pressure PN6 to PN100;

Japanese JIS B2220 & Korean KS B1503 flanges in pressure 5K to 40K;

Russian GOST 12820-80, GOST 12821-80, GOST 12815-80 in pressure PN0.6MPa to PN10MPa;

South African SABS 1123 / SANS 1123 in Class 600kPa to 4000kPa.

Flange Materials:

Carbon Steel: ASTM A105/A105N

A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2

A694 F42, F46, F48, F50, F52, F56, F60, F65, F70

A516.60, 65, 70 (Spectacle Blind Flange, Spacer Ring/Spade Flange)

Steel RST37.2, C22.8

Stainless Steel: ASTM A182 F304/304L, F316/316L, F316H, F316TI, F310, F321;

Alloy Steel: ASTM A182 F1, F5, F9, F11, F22, F91

Duplex & Super Duplext Steel: ASTM A182 F51/UNS S31803, A182 F53/UNS S32750

ASTM A182 F55 / UNS S3260

Flange Face Type: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Flange Norminal Diameter Range: 1/2” – 96”, DN15-DN2000

Normail Pressure Range: 150# - 2500# (PN6 – PN40)

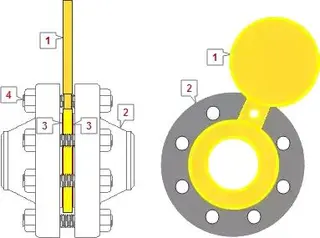

Blind Flange is a flange which has no bore, and is used to close ends of piping systems. A blind flange also permits easy access to a line once it has been sealed. The blind flanges are sometimes machined to accept a pipe of the nominal Size to which reduction is being made. The reduction can be either threaded or welded.

Orifice Flanges are used with orifice plate or flow nozzle for the purpose of measuring the flow rate of either liquids or gases in the respective pipeline. Orifice flanges generally come with either raised faces or RTJ (Ring Type Joint) facings. Pairs of pressure tappings are machined into the orifice flange, making separate orifice carriers or tappings in the pipe wall unnecessary.

In the oil and chemical process industries, a spade is a round piece of metal with a small tab that is placed in between two pipe flanges to give positive isolation from the centre; usually to prevent cross contamination between fluids or to allow work on the line.

Spacer Rings Flanges, Spade Flanges, Special Flanges made in forged steel, Stainless Steel, alloy steel, etc.

Slip on weld Flanges are slipped over the pipe and welded (usually both inside and outside) to provide strength and prevent leakage. Slip-on Flanges are at the low cost end of the scale, and do not require high accuracy when cutting the pipe to length. These SO Flanges can sometimes have a boss or hub, and can be made with a bore to suit either pipe or tube.

Socket Weld Flanges (SW Flanges) are similar to slip-on flanges in outline, but the bore is counter-bored to accept pipe. The diameter of the remaining bore is the same as the inside diameter of the pipe. The Socket Welding Flange is attached to the pipe by a fillet weld around the hub of the flange. An optional internal weld may be applied in high stress applications. The Socket Flanges' biggest use is in high pressure systems such as hydraulic and steam lines.

Threaded Flanges are similar to slip-on flanges in outline, but the bore is threaded, thus enabling assembly without welding. This obviously limits its application to relatively low pressure piping systems. Threaded Flanges may be welded around the joint after assembly, but this is not considered a satisfactory method of increasing the flanges' pressure applications.

Weld Neck Flanges are flanges that designed to be joined to a piping system by butt welding. the WN Flange is relatively expensive because of its long neck, but is preferred for high stress applications. The neck, or hub, transmits stresses to the pipe, reducing stress concentrations at the base of the Welding-Neck flanges. The gradual transition of thickness from the base of the hub to the wall thickness at the butt weld provides important reinforcement of the Weld Neck flange. The bore of the Weld-Neck flange matches the bore of the pipe, reducing turbulence and erosion.

Lap Joint Flanges (LJ Flanges) are used on piping fitted with lapped pipe or with lap joint stub ends the combined initial cost of the two items being approximately one-third higher than that of comparable welding neck flanges. Their pressure-holding ability is little, if any, better than that of slip-on flanges and the fatigue life of the assembly is only one-tenth that of welding neck flanges. The lap joint flange with the stub end assembly are normally used in systems requiring frequent dismantling for inspection and cleaning and where the ability to swivel flanges and to align bolt holes materially eases the erection of large diameter or unusually stiff piping. These flanges are also used in applications where there is a need to facilitate bolt alignment. Their use at points where severe bending stress occurs should be avoided.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

What Is Spectacle Blind Flange?

- Aug 08, 2020

Landee launched Stainless Steel Blind Flange

- Jun 27, 2012

Functions and Applications of Blind Flanges

- Dec 17, 2024

Analyzing the Corrosion of Blind flanges

- Aug 27, 2024

What is Blind Flanges

- Jun 23, 2023

The production process of blind flanges

- Dec 07, 2018

Related Products Mentioned in the Article

Supplier Website

Source: http://www.creatorcomponents.com/blind-flange-threaded-flange-welding-flange-sleep-on-flange-weld-neck-flange.html