How to Find a Reliable Floating Ball Valve Factory in China: A Comprehensive Guide

Introduction

In the global industrial valve market, floating ball valves are among the most widely used and versatile types of valves. Their simple design, reliable sealing performance, and adaptability across various industries make them a staple in pipelines for oil, gas, water, steam, and chemical applications. With China being one of the largest manufacturers of industrial valves, sourcing high-quality floating ball valves from a trusted Chinese factory can offer both cost advantages and technical reliability.

Finding the right floating ball valve manufacturer from China, however, is not as simple as picking the cheapest option. Buyers must consider design quality, material standards, production capabilities, certifications, and after-sales service. This guide provides a detailed look into floating ball valve design, operation, key suppliers in China, and factors to consider when selecting a factory.

Understanding Floating Ball Valve Design

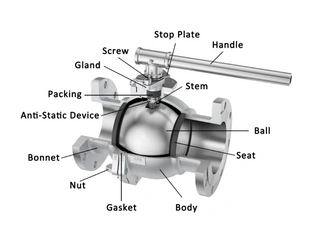

Before searching for a manufacturer, it's important to understand the structure and function of floating ball valves. At their core, floating ball valves consist of several key components:

- Valve Body: The chamber that houses the internal valve mechanism. Common materials include steel, iron, brass, bronze, and PVC.

- Ball: A pivoting sphere with a hollow center (bore) that allows media to flow when aligned with the pipeline. The ball is mounted to the valve stem.

- Bore or Port: The hollow passage through the ball that allows fluid to pass. Full-bore designs allow uninterrupted flow, while reduced-bore options reduce flow capacity.

- Seat: A circular, donut-shaped component made of thermoplastic or metal that forms a tight seal between the ball and the valve body.

- Packing: Sealing elements that prevent media leakage around the stem.

- Stem: A shaft connecting the ball to the actuator or lever. It allows rotational movement of the ball.

- Actuator: External mechanisms that operate the valve, which can include manual levers, gearboxes, electric motors, or pneumatic/hydraulic actuators.

Floating vs. Trunnion Ball Valves

Most ball valves fall into the floating category, where the ball is suspended between two seats and held in position by downstream pressure. Unlike trunnion-mounted valves, which are supported by a fixed shaft, floating ball valves rely on the pressure of the flowing media to maintain a tight seal. This design is lightweight, cost-effective, and ideal for pipelines with moderate pressure ratings.

How Floating Ball Valves Work

The operation is simple yet efficient:

- The stem rotates the ball 90° (a quarter turn).

- When the bore aligns with the pipeline, the valve is open, allowing fluid to pass.

- When the ball turns perpendicular to the flow, it blocks media, creating a tight seal.

The pressure of the media pushes the ball against the downstream seat, enhancing sealing performance. While floating ball valves are effective in most applications, very low-pressure systems may experience minor leakage if seat wear reduces sealing force.

Advantages of Floating Ball Valves

- Bi-directional sealing: Can stop flow in both directions.

- Low maintenance: Minimal moving parts reduce wear and tear.

- Versatility: Suitable for oil, gas, water, petrochemical, and steam pipelines.

- Cost efficiency: Lightweight and less expensive than trunnion-mounted valves for smaller diameters.

- Quick operation: Quarter-turn operation allows fast opening and closing.

Key Considerations When Choosing a Floating Ball Valve Factory in China

Selecting the right manufacturer requires more than just browsing catalogs. Here are crucial factors to consider:

1. Production Capacity and Equipment

A factory with modern production lines and advanced machining capabilities is better equipped to deliver high-quality valves. Look for factories that have CNC machining, forging, casting, and assembly workshops under one roof. State-of-the-art machines ensure tight tolerances, precise bore alignment, and smooth stem operation.

2. Material Quality

Material standards directly affect valve performance and longevity. Reputable Chinese manufacturers use ASTM, DIN, BS, or JIS standards for metals such as:

- Carbon Steel (ASTM A105, A216 WCB)

- Stainless Steel (ASTM A182 F304/F316)

- Alloy Steel (ASTM A350 LF2, WC6/WC1)

- Bronze/Brass (ASTM B148, C95800)

Thermoplastic seats like PTFE, RPTFE, or PEEK are common for floating ball valves, providing chemical resistance and durability.

3. Certifications and Compliance

Top-tier valve factories in China often hold international certifications, including:

- API (6D, 6FA, 600, 602, 603, 609)

- ISO 9001, CE (PED), GOST

- ANSI, ASME B16.34, DIN

These certifications demonstrate adherence to global quality and safety standards, ensuring your valves meet the requirements of critical applications.

4. Customization Capabilities

A strong manufacturer can provide:

- Full-bore, reduced-bore, or V-port designs

- End connections: flange, welded, threaded, or RTJ

- Pressure ratings: Class 150 LB to 2500 LB

- Sizes: from 1/2" to 60" or larger

Custom engineering ensures your floating ball valves meet specific pipeline conditions.

5. Quality Assurance and Testing

Reliable factories conduct rigorous testing:

- Hydrostatic and pneumatic pressure tests

- Leakage tests (API 598)

- Dimensional inspection and surface finish checks

Comprehensive QA reduces defects and prevents costly downtime.

6. Experience and Industry Reach

Manufacturers with decades of experience and global clientele tend to provide better guidance and after-sales support. Their understanding of various industries — oil & gas, petrochemical, water, power, mining — ensures valves are suitable for your application.

Leading Floating Ball Valve Suppliers in China

Several Chinese factories stand out in the floating ball valve market:

Landee Valve (Xiamen, China)

As a division of Landee Industries Co., Ltd, Landee Valve integrates R&D, production, distribution, and service. Their portfolio covers:

- Ball Valves: floating, trunnion, multi-port

- Gate Valves, Globe Valves, Check Valves, Plug Valves

- Safety Valves, Air Valves, Control Valves, Strainers

Applications span oil & gas, petrochemical, chemical, mining, power generation, water control, and construction. Their headquarters in Xiamen has expanded into international markets, building a professional global supply network.

Bosseal Valve (Suzhou, China)

Founded in 2013, Bosseal Valve is a high-precision valve manufacturer with a complete setup, including forging, machining, and valve workshops. Their offerings include:

- Gate Valves for high-pressure pipelines

- Globe Valves for precise flow control

- Check Valves to prevent backflow

- Ball Valves: full bore and trunnion-mounted

- Butterfly Valves: soft-seat and high-performance

- Wellhead Equipment for upstream oil & gas operations

Bosseal combines engineering innovation, quality control, and international sales to serve global clients.

Zhejiang Vervo Valve Co., Ltd

Vervo Valve specializes in floating and trunnion ball valves, cast and forged steel gate and globe valves, cryogenic valves, check valves, butterfly valves, plug valves, and strainers. Key highlights:

- 15,000㎡ modern workshops

- Advanced machines for precision manufacturing

- Certifications: API 6D, 6FA, 6A, 600, 602, 603, 609, ISO 9001, CE, DIN, ANSI

- Global reach: North America, Europe, Asia, Middle East, Africa, Oceania

Vervo Valve emphasizes world-class quality and robust supply capacity for international markets.

Xiamen Weldon Valves Co., Ltd

Weldon specializes in industrial valves across multiple materials and sizes:

- Ball, gate, check, globe, butterfly, plug, safety valves

- Size range: 1/2" to 60"

- Pressure ratings: Class 150 LB to 2500 LB

- Materials: cast steel, forged steel, stainless steel

- Compliance: ANSI, API, BS, DIN, JIS

Weldon ensures 100% quality inspection before delivery and provides solutions tailored to diverse working conditions.

How to Evaluate a Floating Ball Valve Factory

When narrowing down suppliers, consider the following evaluation steps:

1. Factory Visit or Virtual Tour

Seeing the production environment helps verify machinery, workflow, and quality control processes. Many manufacturers offer virtual tours for international buyers.

2. Sample Testing

Request sample valves to inspect machining, material, and assembly quality. Conduct hydrostatic and operational tests if possible.

3. Customer References

Ask for references in similar industries or regions. Feedback on performance, delivery times, and post-sales service can reveal the supplier's reliability.

4. Technical Support

Top factories provide engineering consultation, sizing recommendations, and installation guidance. This reduces operational risks and ensures correct valve selection.

5. Lead Time and Logistics

Assess production lead times, shipping options, and packaging standards. Reliable factories have experience with international shipping, customs clearance, and packaging for protection during transit.

Floating Ball Valve Applications

Floating ball valves are widely used due to their versatility:

- Oil & Gas: For upstream, midstream, and downstream pipelines, handling crude, refined products, and natural gas.

- Petrochemical: Managing corrosive chemicals and high-temperature processes.

- Water & Wastewater: Controlling flow in municipal and industrial water systems.

- Power Generation: Steam and cooling water lines in thermal and nuclear plants.

- Mining: Slurry and water control in harsh environments.

- Food & Beverage: Hygienic valves with PTFE or FDA-approved seats for fluid control.

Their adaptability, combined with easy maintenance and tight sealing, makes them suitable for virtually any medium.

Conclusion

Finding a reliable floating ball valve factory in China requires careful research, evaluation of production capacity, quality standards, certifications, and customer service. Leading manufacturers like Landee Valve, Bosseal Valve, Zhejiang Vervo Valve, and Xiamen Weldon Valves offer high-quality valves and a wide range of industrial solutions for global markets.

Understanding floating ball valve design, function, and application helps buyers make informed decisions. By prioritizing material quality, testing standards, customization, and supplier credibility, industrial buyers can ensure a reliable and long-lasting valve solution for their pipelines. With the right partner, sourcing from China can combine cost efficiency with high performance, ensuring seamless operation in demanding industrial applications.

Previous: How to Buy Safety Valves from Reliable Chinese Manufacturers