How to Choose Leading Trunnion Mounted Ball Valve Suppliers in China

Introduction

As global energy, chemical, and infrastructure projects continue to expand, the demand for high-performance industrial valves has never been greater. Among the many valve types used in critical pipeline systems, trunnion mounted ball valves stand out for their ability to handle high pressure, large diameters, and severe operating conditions with exceptional reliability.

China has become one of the world's most important manufacturing centers for industrial valves, supplying trunnion mounted ball valves to oil and gas projects, petrochemical plants, power stations, water transmission systems, and LNG facilities worldwide. However, with hundreds of valve manufacturers operating in the Chinese market, selecting the right trunnion mounted ball valve supplier can be challenging.

This article provides a comprehensive guide on how to choose leading trunnion mounted ball valve suppliers in China. It explains what trunnion mounted ball valves are, how they work, why supplier selection matters, and what key factors buyers should evaluate when sourcing from Chinese manufacturers.

What Are Trunnion Mounted Ball Valves?

Ball valves are widely used in industrial piping systems due to their simple quarter-turn operation, compact structure, bi-directional sealing capability, and excellent shutoff performance. Despite the many variations in body design, seat materials, and end connections, ball valves are primarily divided into two categories based on how the ball is supported within the valve body:

- Floating Ball Valves

- Trunnion Mounted Ball Valves

Floating Ball Valves

In a floating ball valve, the ball is not mechanically fixed in place. Instead, it is held between two valve seats and is allowed to “float” slightly under fluid pressure. When the valve closes, the pressure of the media pushes the ball against the downstream seat, creating a seal.

Floating ball valves are commonly used in smaller sizes and lower pressure applications. As valve size and pressure increase, the force exerted on the ball also increases, which can lead to excessive seat wear, higher operating torque, and limitations in sealing performance.

Trunnion Mounted Ball Valves

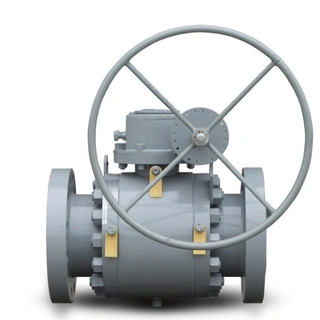

Trunnion mounted ball valves use a fundamentally different design. In this configuration, the ball is mechanically supported by trunnions (pivot pins) at the top and bottom. The stem connects to the top trunnion, while the bottom trunnion stabilizes the ball, preventing axial movement caused by line pressure.

This design allows the ball to remain fixed in position while the seats move toward the ball to achieve sealing. As a result, trunnion mounted ball valves are ideally suited for large diameters, high pressures, and demanding service conditions.

Key Advantages of Trunnion Mounted Ball Valves

Trunnion mounted ball valves offer several technical and operational advantages that make them essential in critical applications:

Reduced Operating Torque

Because the ball is supported by trunnions, line pressure does not force the ball into the seats. This significantly reduces operating torque, making these valves easier to operate manually and ideal for actuator-driven automation.

Enhanced Sealing Performance

The floating seat design ensures consistent contact between the seat and the ball, even under fluctuating pressure conditions. This improves sealing reliability and reduces leakage risk.

Longer Service Life

Lower friction and controlled ball movement reduce wear on seats and sealing components, extending the valve's operational life.

Suitability for High Pressure and Large Size

Trunnion mounted ball valves are commonly used in Class 300 to Class 2500 pressure ratings and in sizes exceeding 16 inches, where floating ball valves are no longer practical.

Advanced Safety Features

Many trunnion mounted ball valves are equipped with fire-safe designs, anti-static devices, emergency sealant injection systems, and double block and bleed (DBB) or double isolation and bleed (DIB) configurations.

How Trunnion Mounted Ball Valves Operate

Operation of a trunnion mounted ball valve is straightforward and efficient. When the valve stem is rotated by 90 degrees, the ball turns within the valve body to either allow or block fluid flow.

- Open Position: The bore of the ball aligns with the pipeline, allowing unrestricted flow.

- Closed Position: The solid portion of the ball blocks the flow path, while the seats press firmly against the ball to form a tight seal.

Trunnion mounted ball valves can be operated using:

- Manual levers or gear operators

- Pneumatic actuators

- Electric actuators

- Hydraulic actuators

Remote operation is particularly valuable in offshore platforms, underground pipelines, high-temperature environments, and locations where frequent operation or emergency shutdown capability is required.

Why Choosing the Right Supplier in China Matters

China's valve manufacturing industry is vast and diverse. While many Chinese suppliers offer competitive pricing, not all manufacturers meet the same standards of quality, engineering capability, and project support. Choosing the right supplier directly affects:

- Operational safety

- System reliability

- Maintenance costs

- Project timelines

- Long-term performance

A leading trunnion mounted ball valve supplier will not only manufacture valves but also provide technical expertise, quality assurance, and responsive after-sales service.

Key Criteria for Selecting Leading Trunnion Mounted Ball Valve Suppliers in China

1. Manufacturing Capability and Facilities

Reputable suppliers operate modern manufacturing facilities with complete in-house capabilities, including:

- Forging or casting

- CNC machining

- Welding and heat treatment

- Assembly and testing

Advanced equipment ensures dimensional accuracy, consistency, and compliance with international standards.

2. Compliance with International Standards

Leading suppliers manufacture trunnion mounted ball valves in accordance with recognized global standards such as:

- API 6D

- API 6FA (Fire Safe)

- API 607

- ASME B16.34

- ISO 9001

- CE (PED)

Certifications demonstrate that the manufacturer follows standardized quality systems and testing procedures.

3. Material Range and Customization

A reliable supplier should offer a wide range of materials, including:

- Carbon steel (A105, A350 LF2, WCB)

- Stainless steel (F304, F316, CF8M)

- Low-temperature steel

- Alloy steel (F11, F22, F51, F53)

- Special materials for sour service and corrosive media

Customization capabilities are essential for meeting project-specific requirements.

4. Testing and Quality Control

Leading manufacturers perform comprehensive inspections and testing, such as:

- Hydrostatic pressure testing

- Seat leakage testing

- Fire testing

- Non-destructive testing (RT, UT, MT, PT)

- Dimensional inspection

Strict quality control ensures every valve meets design and performance expectations before delivery.

5. Industry Experience and Project References

Suppliers with proven experience in oil and gas, petrochemical, LNG, power generation, and pipeline projects are better equipped to handle complex requirements and large-scale orders.

Overview of Leading Trunnion Mounted Ball Valve Suppliers in China

Landee Valve (Landee Industries Co., Ltd)

Landee Valve is a modern, technology-driven valve manufacturer integrating research, production, sales, and service. As part of Landee Industries, the company offers a comprehensive range of industrial valves, including trunnion mounted ball valves, gate valves, globe valves, check valves, butterfly valves, and control valves.

With applications spanning oil and gas, petrochemical, power generation, water control, mining, and construction, Landee Valve has built a strong international presence. Its headquarters in Xiamen supports a global distribution network, making Landee one of the most recognized Chinese valve suppliers worldwide.

Bosseal Valve (Suzhou) Co., Ltd

Founded in 2013 and headquartered in Suzhou, Bosseal Valve is known for its high-quality industrial valves and wellhead equipment. The company operates integrated production facilities covering forging, machining, and valve assembly, supported by rigorous quality control systems.

Bosseal's product portfolio includes trunnion mounted ball valves, gate valves, globe valves, check valves, butterfly valves, and high-pressure wellhead equipment. The company has earned a strong reputation for technical expertise, innovation, and reliable performance in demanding applications.

Zhejiang Vervo Valve Co., Ltd

Zhejiang Vervo Valve Co., Ltd is one of China's largest industrial valve manufacturers, specializing in floating and trunnion ball valves, gate valves, globe valves, check valves, butterfly valves, plug valves, and strainers.

With approximately 15,000 square meters of workshop space and state-of-the-art machinery, Vervo serves markets across North America, Europe, the Middle East, Asia, Africa, and Oceania. The company holds numerous certifications, including API, ASME, DIN, JIS, ISO, CE, and GOST, reflecting its commitment to international standards.

Xiamen Weldon Valves Co., Ltd

Weldon Valves focuses on manufacturing and developing industrial valves tailored to diverse customer requirements. Its product range includes ball valves, gate valves, globe valves, check valves, safety valves, butterfly valves, and strainers, covering sizes from 1/2 inch to 60 inches and pressure classes up to 2500 LB.

Weldon emphasizes strict inspection, professional technical training, and responsive customer service, making it a reliable supplier for global pipeline and industrial projects.

How to Evaluate and Compare Suppliers Effectively

When selecting a trunnion mounted ball valve supplier in China, buyers should:

- Request detailed technical datasheets

- Review certifications and audit reports

- Evaluate past project experience

- Assess communication efficiency and technical support

- Verify testing and inspection procedures

Factory audits, third-party inspections, and sample orders can further reduce procurement risk.

Future Trends in Trunnion Mounted Ball Valve Manufacturing

As global industries evolve, Chinese valve manufacturers are increasingly investing in:

- Smart valve technology and automation

- Digital manufacturing and quality traceability

- Advanced materials for extreme environments

- Enhanced fire-safe and low-emission designs

These developments continue to strengthen China's position as a global supplier of high-performance trunnion mounted ball valves.

Conclusion

Choosing a leading trunnion mounted ball valve supplier in China requires careful evaluation of manufacturing capability, quality systems, certifications, and industry experience. Trunnion mounted ball valves play a critical role in ensuring safety, efficiency, and reliability in high-pressure and large-diameter pipeline systems.

By partnering with reputable Chinese manufacturers such as Landee Valve, Bosseal Valve, Zhejiang Vervo Valve, and Weldon Valves, global buyers can access competitively priced, technically advanced, and internationally compliant valve solutions. With the right supplier, trunnion mounted ball valves deliver long-term performance, reduced maintenance, and dependable operation across the most demanding industrial applications.

Previous: How to Buy Stainless Steel Pipes from China Manufacturers