Ductile Iron Diaphragm Valves, BS 5156, MSS SP-88, DN100, RF

Key Specifications / Features

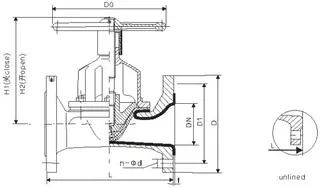

The Ductile Iron Diaphragm Valves Plant produces reliable Straight Through Diaphragm Valves designed in accordance with BS 5156 and MSS SP-88 standards. These valves feature a durable ductile iron body, ensuring strength and longevity. With a DN100 (4 inch) size and rated at PN10, Class 150 LB, they are equipped with raised face (RF) flanged ends for secure and leak-free connections. The handwheel provides easy operation for manual control.

Detail Information

Product Name: Ductile Iron Diaphragm Valves

Type: Straight Through Diaphragm Valve

Design Standard: BS 5156, MSS SP-88

Body Material: Ductile Iron

Size: DN100, 4 Inch

Pressure: PN10, Class 150 LB

End Connection: RF Flanged

Operation: Handwheel

Temperature Range: -29°C to 80°C

When the straight-through diaphragm valve is opened, its diaphragm rises, enabling smooth flow in any direction. When the valve is closed, the diaphragm seal is tight, ensuring absolute closure even in pipelines containing gravel or fiber. Compared to weir diaphragm valves, this valve requires a more elastic diaphragm. Consequently, this structure limits the range of suitable elastic materials for the diaphragm.

Corrosion Resistance: Diaphragm valves are the ideal choice for applications requiring corrosion resistance. We offer a wide range of linings and diaphragms to meet most needs. This extensive selection of body lining and diaphragm materials provides an effective and economical solution by eliminating the need for exotic alloys. Our comprehensive range of valve options includes elastomer and fluoropolymer linings, specifically designed to combat corrosion.

Abrasion Resistance: Our polymer technology offers superior abrasion resistance. The straight-through valve can handle up to 100% solids and, with a soft rubber diaphragm, still achieve tight shut-off, in accordance with standards MSS SP-88 and BS EN 12266-1.

Leak Tight: In both pressure and vacuum services, KOSEN diaphragm valves operate and close 100% leak tight, in accordance with standards MSS SP-88 and BS EN 12266-1. This performance is maintained even after thousands of operations, reducing processing and handling costs by eliminating emissions typically associated with other valve types.

Operating Mechanism: All working parts of the valves are isolated from the line media, ensuring positive closure even with frequent cycling or entrained particulates in the line. Unlike other valve types, the operating mechanism does not come into contact with the line media.

Easy Maintenance: The three-part design allows for maintenance and actuator retrofitting without the need to remove the valve body from the pipeline. This design results in lower overall ownership costs compared to other valve types.

Suitable for Control: The streamlined flow path, which is cavity-free, enhances throttling and control characteristics, providing excellent flow control capabilities.

Standards Compliance and Design Features

» Size: 3/4-16 Inch (DN20-DN400)

» Pressure Rating: ANSI Class 125 LB, Class 150 LB, PN6, PN10, PN16

» All Standards: MSS SP-88, BS 5156, ASME B16.34, DIN 3202, ASME B16.1, BS EN 558, ASME B16.5 CL150, EN 1092, EN 12226, ISO 5208, API 598, BS 4504 or equivalents

» Material: Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel, ASTM A216 WCB, A351 CF8, CF8M

» Optional Lining: Hard Rubber (Ebonite), Natural, Neoprene, Hypalon, Butyl, EPDM, FEP, PFA

» Diaphragms: Natural Rubber, Butyl, EDPM, Hard Rubber, etc.

» Ends Connections: Flanged RF or FF, Screwed

» Operation: Handwheel, Pneumatic, Electric Operated

» Temperature Range: -29°C to 80°C

» Optional Locking Device Position indicator

» Optional Direct Mounting to ISO 5211

» Regular Bore

Structural Diagram

Main Material

|

Item No |

Part Name |

Material |

|

1 |

Body |

Cast Iron, carbon steel, Stainless steel |

|

2 |

Bonnet |

Cast Iron, carbon steel, Stainless steel |

|

3 |

Lining |

Rubber lining and fluorine lining |

|

4 |

Diaphragm |

Rubber |

|

5 |

Disc |

Cast Iron, carbon steel |

|

6 |

Stem |

carbon steel, Stainless steel |

|

7 |

Handweel |

Cast Iron |