Pneumatic Three Way Control Valve, A216 WCC, 6 Inch, 150 LB

Key Specifications / Features

Detail Information

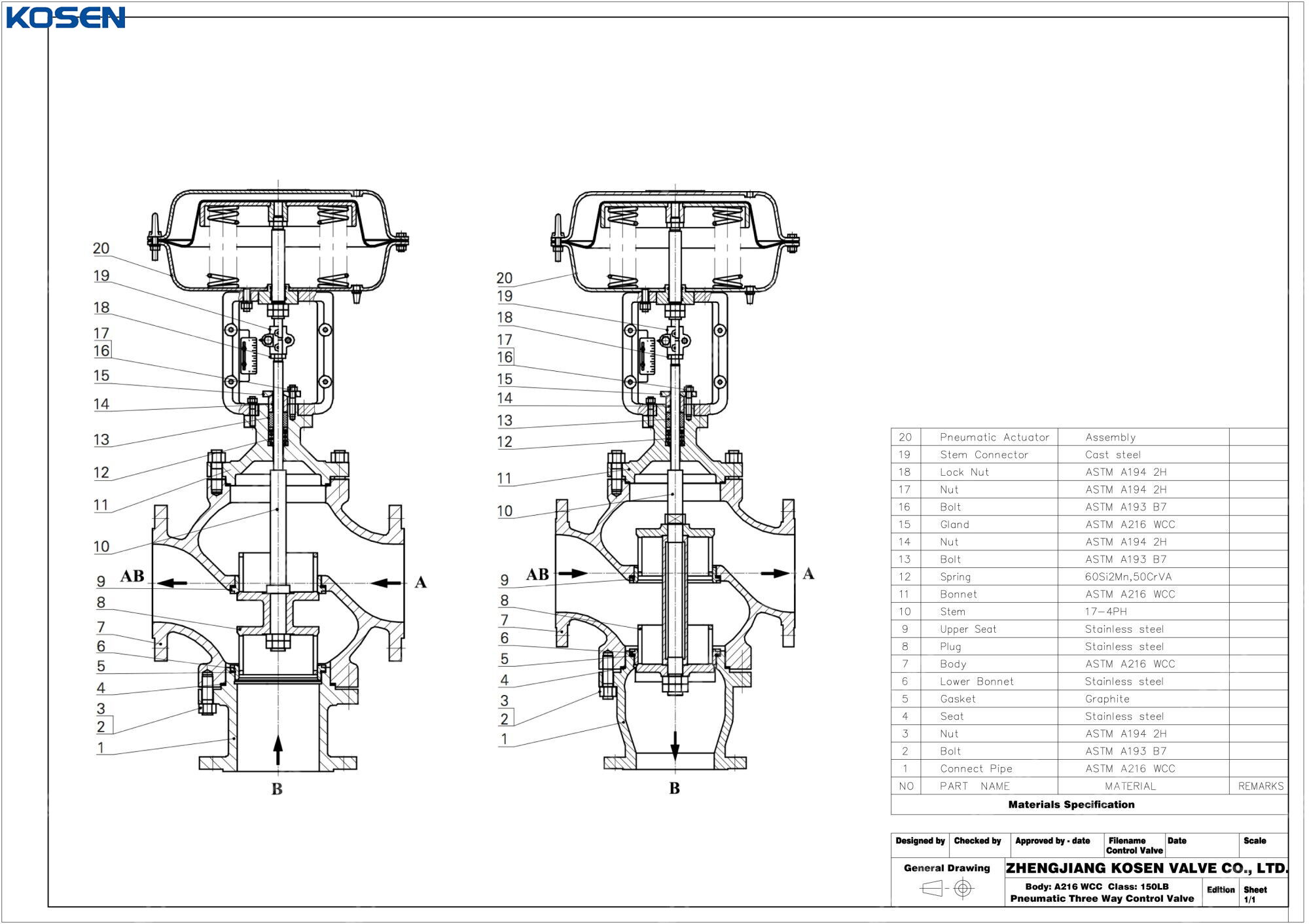

Product Name: Pneumatic Three Way Control Valve

Position Type: Mixing Type

Body Material: ASTM A216 WCC

Size: 6 Inch, DN150

Pressure: Class 150 LB, PN20

End Connection: RF Flanged

Operation: Pneumatic Actuator

Characteristic: Linear, Equal Percentage

Voltage: Depends on Accessory

Feature: Pneumatic Control Valve Manufacturer, Factory, and Supplier

The regulating valve, also known as the control valve, serves as the final control element in industrial automation process control systems. It regulates process parameters such as medium flow, pressure, temperature, and liquid levels by responding to control signals output by the regulating control unit. The valve operates through an actuator, which provides power for its movement. Regulating valves are classified by their stroke characteristics (straight stroke or angular stroke), the power source used by the actuator (pneumatic, electric, or hydraulic), and their function (linear, equal percentage, or parabolic characteristics). These valves are versatile, suitable for a wide range of media, including air, water, steam, corrosive substances, mud, and oil. The primary types of control valves are pneumatic control valves, electric control valves, hydraulic control valves, and self-operated control valves.

Product Structure and Features

» Valve Core Shape Structure

The selection of the valve core shape is determined based on the desired flow characteristics and the forces acting on the valve. Proper design ensures efficient control and minimizes wear or damage to components.

» Wear Resistance

In systems where the fluid contains abrasive particles, such as suspensions, the valve core and other internal components should be made from wear-resistant materials. This ensures the longevity and reliable performance of the valve in harsh conditions.

» Corrosion Resistance

For media that are corrosive in nature, it is essential to select a valve with a simple structure and materials that provide excellent corrosion resistance. This helps prevent degradation of the valve and ensures long-term durability.

» Temperature and Pressure of Medium

For media with high or fluctuating temperatures and pressures, selecting a valve with materials for the valve core and seat that are resistant to temperature and pressure changes is crucial. Additionally, for temperatures above 250°C, a radiator should be incorporated to dissipate excess heat and maintain stable operation.

» Prevention of Flash and Cavitation

Flashing and cavitation are phenomena that occur in liquid media when pressure drops below the vapor pressure of the fluid, leading to bubbles that collapse, causing vibration, noise, and damage to the valve. To avoid these issues, proper valve selection should prevent these occurrences, thereby enhancing the valve’s service life and reducing operational disruptions.

Technical Specification

|

Body Type |

3-Way Casting Globe Type |

|

Spool Type |

3-Way Double Seat Spool |

|

Nominal Size |

DN20-300, NPS 3/4-12 Inch |

|

Nominal Pressure |

PN16-PN100, Class 150-600 LB |

| Body Material |

ASTM A216 WCB, A352 LCB, A351 CF8, CF3, CF8M, CF3M, etc. |

|

Connection: Flange |

FF, RF, MF, RTJ |

|

Welding |

SW, BW |

|

Flange Dimension |

According to to IEC 60534 |

|

Pneumatic 3-way Control Valve |

Ⅰ: Standard type(-20°C to 230°C) |

|

Packing |

V type PFTE packing, flex. graphite packing, etc. |

|

Gasket |

Metal graphite packing |

|

Control valve Actuator |

Pneumatic:multi-spring diaphragm actuator, piston type actuator |