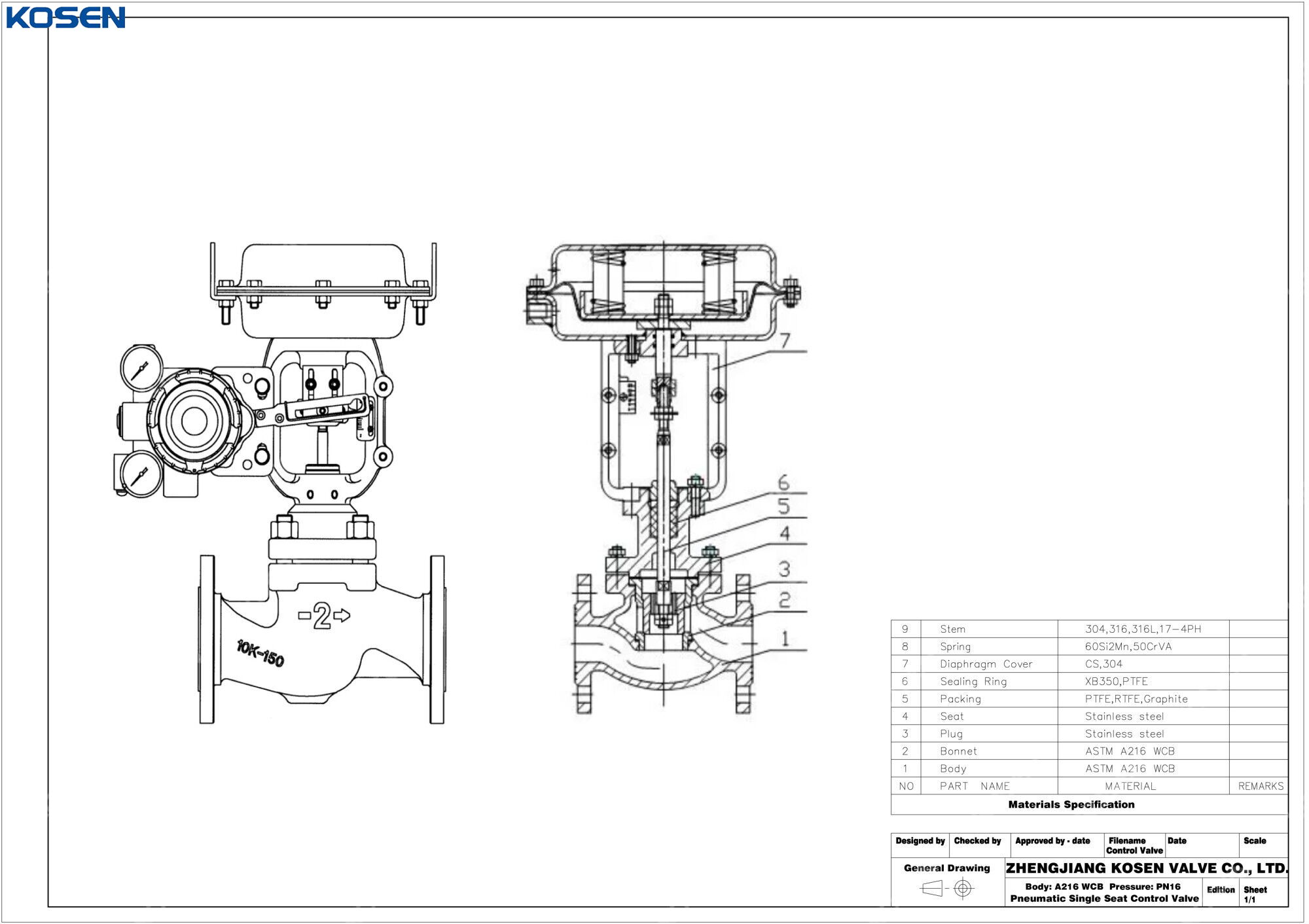

Pneumatic Single Seat Control Valve, WCB, 1-1/4 Inch, 150 LB

Key Specifications / Features

Detail Information

Product Name: Pneumatic Globe Control Valve, Single Seat

Body Material: ASTM A216 WCB

Size: 1-1/4 Inch, DN32

Pressure: Class 150 LB, PN16

End Connection: RF Flanged

Operation: Pneumatic Actuator

Product Range

Port Size: DN15-DN300, 1/2-12 Inch

Pressure: PN10-PN64, Class 150-600 LB

Medium: Water, Steam, Oil, etc.

Temperature: -29℃ to 425℃

Body Material: ASTM A216 WCB, A217 WC6, WC9, A351 CF8, CF8M, etc.

Connection: Flange, Welding

Position Type: 4-20mA signal control

Characteristic: Linear, Equal percentage, Quick open

Voltage: Depending on accessory

Feature: Pneumatic Control Valve Manufacturer, Factory, and Supplier

The regulating valve, also known as the control valve, is a key component in industrial automation process control. It adjusts process parameters such as medium flow, pressure, temperature, and liquid level by receiving control signals from the regulating control unit and using power to operate. The valve typically consists of an actuator and valve body.

Regulating valves can be categorized in the following ways:

Stroke Characteristics: Straight stroke or angular stroke.

Power Source: Pneumatic control valve, electric control valve, or hydraulic control valve.

Function and Characteristics: Linear characteristics, equal percentage characteristics, and parabolic characteristics.

These valves are suitable for a wide range of media, including air, water, steam, corrosive substances, mud, and oil. Common types of control valves include pneumatic, electric, hydraulic, and self-operated control valves.

Product Structure and Features

» Valve Core Shape Structure: The valve core design is determined by the selected flow characteristics and unbalanced force.

» Wear Resistance: For fluids containing high concentrations of abrasive particles (e.g., suspensions), the valve’s internal materials should be hardened to resist wear.

» Corrosion Resistance: For corrosive media, it's advisable to select valves with simple structures to minimize vulnerability to corrosion.

» Temperature and Pressure of Medium: When the medium’s temperature and pressure are high or fluctuate significantly, the valve core and valve seat material should be chosen for minimal temperature and pressure sensitivity. If the temperature exceeds 250°C, a radiator should be added.

» Prevention of Flashing and Cavitation: Flashing and cavitation are phenomena that occur in liquid media, creating vibrations, noise, and reducing valve life. Valves should be selected to prevent these issues during operation in such conditions.