Air Operated Pinch Valve, Aluminum, DN40-DN300, 2-6 Bar

Key Specifications / Features

Detail Information

Product Name: Air Operated Pinch Valve

Body: Aluminum

Nominal Size: DN40-DN300, 1-1/2 Inch to 12 Inch

Working Pressure: 2-6 bar

Socket Type: Flange (DIN)

Sockets: Aluminum with Steel Bushing

Sleeve: Natural Rubber, EPDM

Sealing Grade: ANSI B16.104 Class

Working Temperature: -20°C to +150°C

The pinch valves are ideal for shut-off or control applications involving abrasive or corrosive slurries, powders, or granular substances. Our advanced flow control solutions are designed to meet even the most demanding customer specifications. KOSEN valves enhance productivity by improving process efficiency and extending service intervals.

The pinch valve features three main components: the sleeve, the body, and the actuator. The sleeve is the only part in contact with the process medium, and the materials used for all three components can be selected to suit various process conditions. The pinch valves provide 100% tight shut-off, even when solids accumulate on the sleeve wall. When compressed, any crystallized particles flake off the sleeve surface and are washed downstream, ensuring consistent performance.

Product Accessories

Solenoid valve, pressure switch, pressure regulator, safety protection device, filter, vacuum assembly, proportional regulating valve.

Jacket Type

Wear-resistant natural rubber, food safety natural rubber, high-temperature resistant natural rubber, EPDM, black food safety natural rubber, light-colored food safety natural rubber, nitrile rubber, black food safety nitrile rubber, light-colored food safety nitrile rubber, fluororubber, silicone resin, neoprene, chlorosulfonated polyethylene rubber, butyl rubber, and other materials.

Product Advantages

◆ The key advantages of pneumatic pinch valves include smooth medium flow, minimal friction resistance, 100% no leakage, no blockage, and lightweight construction.

◆ The shells of all flanged pinch valves are flat and oval, ensuring low compressed air consumption. This not only saves energy but also guarantees the predetermined lip bending direction of the pneumatic pinch valves.

◆ The predetermined lip bending direction ensures 100% shut-off of the medium flow and provides a complete shut-off even when large solid particles cover the inner bushing.

Product Use

Pneumatic pinch valves are used for shut-off, regulation, and quantification of wear, corrosive, and fibrous media, including solutions for particles, powdery materials, pellets, dust, and liquids containing solids. The pinch valve is suitable for various pneumatic conveying systems. Its applications span across industries such as cement silos, pigment and particle treatment, ceramics, glass, plastics, sewage treatment, pharmaceuticals, food, and wine brewing.

Matters Needing Attention

◆ Always turn off the air supply and disconnect proximity air before replacing the inner bushing, cleaning the pinch valve, or performing any operation.

◆ During operation, ensure that no body parts, tools, or other special bodies come into contact with the pinch valve.

◆ Follow the instructions in the safety data sheet before the valve comes into contact with the conveying medium/product.

◆ When the conveying temperature of the medium is high, avoid touching the pinch valve (risk of burns).

◆ Only disassemble the pinch valve when the equipment is shut down and free from pressure.

◆ To prevent overload of the pinch valve’s maximum allowable working/control pressure, the equipment should be equipped with a pressure limiter and safety valve.

◆ Do not use unstable working mediums.

◆ Note that the applied medium or the pinch valve’s environment may generate static electricity.

◆ When selecting materials for the pinch valve, consider not only the service life of the valve itself but also the durability of driving parts (e.g., gas circuit control, solenoid valve). If the inner bushing is damaged, the medium may enter the control circuit.

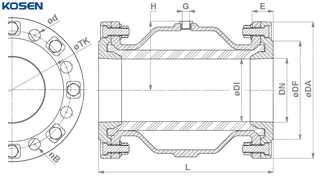

Main Connection Size and Weight (mm)

|

DN |

DI |

DA |

DF |

nB |

d |

TK |

L |

G |

H |

E |

Weight (kg) |

Volume (I) |

max. (bar) |

Thread |

GT (mm) |

|

40 |

40 |

150 |

88 |

4 |

18 |

110 |

155 |

G1/4" |

56 |

28 |

2,9 |

0, 20 |

6 |

1½" |

19 |

|

50 |

50 |

165 |

102 |

4 |

18 |

125 |

183 |

G1/4" |

65 |

30 |

3,8 |

0, 30 |

6 |

2 |

24 |

|

65 |

65 |

185 |

122 |

4 |

18 |

145 |

183 |

G1/4" |

81 |

28 |

4,3 |

0, 45 |

6 |

2½" |

22 |

|

80 |

80 |

200 |

138 |

8 |

18 |

160 |

228 |

G1/4" |

95 |

31 |

5,6 |

0, 95 |

6 |

3 |

22 |

|

100 |

100 |

220 |

158 |

8 |

18 |

180 |

280 |

G1/4" |

112 |

35 |

8,5 |

1, 70 |

6 |

4 |

20 |

|

125 |

118 |

250 |

184 |

8 |

18 |

210 |

348 |

G1/4" |

136 |

40 |

12,1 |

3, 50 |

6 |

/ |

/ |

|

150 |

145 |

285 |

212 |

8 |

22 |

240 |

418 |

G1/4" |

160 |

43 |

17,0 |

7, 00 |

6 |

/ |

/ |

|

200 |

190 |

340 |

268 |

8 |

22 |

295 |

558 |

G3/8" |

206 |

60 |

33,2 |

15, 50 |

4 |

/ |

/ |

|

250 |

250 |

395 |

320 |

12 |

22 |

350 |

680 |

G1/2" |

266 |

67 |

56,0 |

30, 00 |

3 |

/ |

/ |

|

300 |

300 |

445 |

370 |

12 |

22 |

400 |

820 |

G1/2" |

306 |

70 |

86,0 |

49, 00 |

3 |

/ |

/ |