Globe Valves vs. Diaphragm Valves: How to Choose?

In industrial pipeline systems, valves play a vital role. They are like loyal guards, precisely controlling the flow of fluids and ensuring the safe and efficient operation of the entire system. Today, let us take a closer look at two common types of valves, globe valves and diaphragm valves. Each has its unique structure, advantages, and application scenarios, making them indispensable components in the industrial field.

Globe Valve: Reliable Precise Regulation

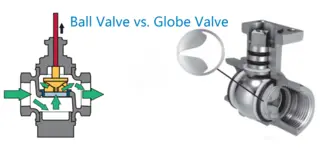

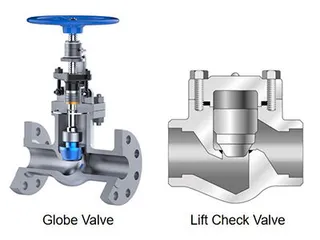

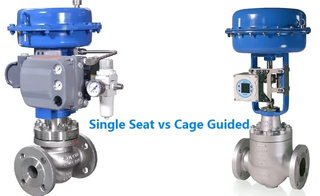

The globe valve is a widely used type of valve. Its closing part (the disc) moves along the centerline of the valve seat. This unique movement means that the change in the valve seat opening is directly proportional to the stroke of the disc. Imagine this: as the disc gradually moves, the opening size of the valve also changes in a regulated way, enabling precise flow control. Moreover, the stem’s opening or closing stroke is relatively short, which means that in operation, we can quickly switch the valve on and off while ensuring reliable shut-off performance.

1. Numerous Advantages, Wide Applications

The globe valve is favored because it offers a range of significant advantages. First, it has good wear resistance. During opening and closing, the friction between the disc and the sealing surface of the body is smaller than that of gate valves, allowing the globe valve to maintain good performance even with frequent operation and prolonging its service life. Second, the opening height of a globe valve is usually only 1/4 of the valve seat passage, making its size much smaller than that of a gate valve, particularly useful in limited spaces. In addition, the globe valve usually has only one sealing surface on the body and disc, giving it better manufacturability and making maintenance easier. Furthermore, because its packing is generally a mixture of asbestos and graphite, the globe valve has high temperature resistance and can adapt to high-temperature environments, which is why steam valves usually use globe valves.

2. Reliable Sealing

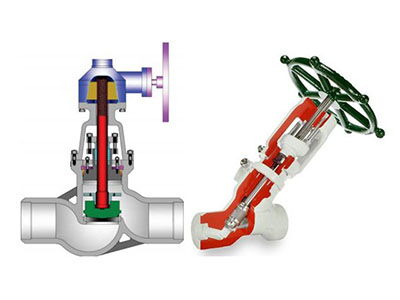

The globe valve is a forced-sealing type valve, which means that when the valve is closed, a certain pressure must be applied to the disc to ensure tight contact between sealing surfaces and prevent medium leakage. When the medium enters the cavity from below the disc, the operating force must overcome the friction of the stem and packing, as well as the thrust generated by the medium pressure. In this case, the force required to close the valve is greater than to open it, so the stem diameter must be sufficiently large; otherwise, the stem may bend. However, with the advent of self-sealing valves, the flow direction of the medium in globe valves has changed, and now the medium usually enters the cavity from above the disc. In this way, under the action of medium pressure, the closing force becomes smaller while the opening force increases, and the stem diameter can be reduced accordingly. At the same time, this structure also provides tighter sealing under medium pressure. China once stipulated that the flow direction of globe valves must be from top to bottom, also to enhance sealing performance.

3. Flexible Flow Regulation

The opening height of the globe valve directly affects the flow. When the opening height reaches 25%–30% of the nominal diameter, the flow already reaches its maximum, at which point the valve is fully open. Therefore, the fully open position of the globe valve is determined by the stroke of the disc. This characteristic makes the globe valve highly flexible for flow regulation, allowing precise control according to actual needs. However, globe valves also have limitations. They are not suitable for media with particles, high viscosity, or easy coking, as such media may accumulate between the disc and sealing surface, affecting sealing or even preventing proper closure. Moreover, the sealing surfaces of globe valves only make contact when fully closed, and the relative sliding amount between the forced-closed core and sealing surface is very small, resulting in little wear. But if debris exists between the disc and sealing surface, or if closure is not tight enough, the medium may cause high-speed erosion, accelerating wear on the sealing surface.

4. Installation Methods

When installing a globe valve, the medium can enter from below the disc or from above, each method having its own advantages and disadvantages. If the medium enters from below, the advantage is that the packing is not under pressure when the valve is closed, prolonging its service life, and packing can be replaced while the pipeline before the valve is pressurized. However, the disadvantage is that the driving torque of the valve is larger, about 1.05–1.08 times that of top entry, and the stem is subjected to greater axial force, making it more prone to bending. Therefore, this method is generally only suitable for small-diameter manual globe valves, and limited to cases where the force exerted on the disc when closed does not exceed 350 kg. Imported electric globe valves generally use top-entry installation, whose disadvantages are the opposite.

Diaphragm Valve: Shut-off Function

The diaphragm valve is a special form of shut-off valve with a structure very different from ordinary valves. Inside the body and bonnet is a flexible diaphragm or composite diaphragm. The closing part is a compression device connected to the diaphragm. The valve seat can be weir-type or a straight-through channel wall. This unique structure gives diaphragm valves distinct advantages in industrial applications.

1. Simple and Efficient

The diaphragm valve has a simple structure, mainly composed of three parts: the body, the diaphragm, and the bonnet assembly. This simplicity allows diaphragm valves to be quickly disassembled and maintained, with diaphragm replacement completed on-site in a short time, greatly reducing downtime and costs. In addition, diaphragm valves have low fluid resistance and larger flow capacity compared to other valves of the same size, meaning they can achieve higher throughput with the same pipeline size. More importantly, diaphragm valves are leak-free and suitable for regulating viscous media and media with suspended particles, making them unmatched in handling special fluids.

2. Diaphragm Protection, Worry-Free Sealing

The diaphragm is the core component of a diaphragm valve. It separates the cavity inside the body from the cavity inside the bonnet and the driving parts. Because of this separation, the medium is isolated from the upper chamber of the stem, ensuring that there is no packing and no leakage of the medium. This not only keeps the working medium pure but also prevents the medium from impacting the moving parts of the operating mechanism. Furthermore, no additional stem sealing is required unless used as a safety measure in handling hazardous media. This design greatly enhances reliability and safety, especially in applications with extremely high sealing requirements.

3. Diverse Options to Meet Different Needs

The body of diaphragm valves may be made of cast iron, cast steel, or cast stainless steel, lined with various corrosion- or wear-resistant materials. Diaphragms are available in rubber, PTFE, and other materials. These combinations allow diaphragm valves to adapt to many different working media. For example, lined diaphragms have strong corrosion resistance and are suitable for regulating highly corrosive media such as strong acids and alkalis. Moreover, the separation of the operating mechanism from the flow path further enhances stability and reliability. Since only the diaphragm and body come into contact with the medium, and both can be made of various materials, diaphragm valves are ideal for controlling a wide range of media, especially corrosive or particle-laden ones.

4. Limited Scope, Clear Advantages

Although diaphragm valves have many advantages, their application range is somewhat limited. Due to the limitations of diaphragm and lining materials, they have poor pressure and temperature resistance, generally suitable only for nominal pressures up to 1.6 MPa and temperatures below 150°C. Furthermore, because of restrictions in lining and diaphragm manufacturing processes, larger sizes are difficult to produce, so diaphragm valves are usually applied in pipelines with DN ≤ 200 mm. However, their advantage lies in their ability to handle corrosive, viscous, or particle-containing media with excellent sealing, as the medium only contacts the diaphragm and not the body. Therefore, diaphragm valves are particularly suitable for applications requiring high hygiene and no contamination, such as in pharmaceuticals, food, and beverages.

Choosing the Right Valve

Globe valves and diaphragm valves are both essential components in industrial pipeline systems, each with its own unique structure and advantages. Globe valves, with their reliable shut-off performance, wear resistance, and good flow regulation ability, are widely used in various industrial settings, especially where flow control is critical. Diaphragm valves, with their simple structure, excellent sealing, and adaptability to special media, perform exceptionally in handling viscous, particle-laden, and corrosive media, making them an ideal choice for industries such as pharmaceuticals, food, and beverages.

When selecting valves, we need to consider the specific working conditions, medium characteristics, pressure, and temperature requirements, and comprehensively evaluate performance and suitability. Only by choosing the right valve can we ensure the safe and efficient operation of industrial pipeline systems and provide solid support for industrial production. Whether globe valves or diaphragm valves, both play important roles in their respective fields and are reliable partners in industrial development.

Send your message to this supplier

Related Articles from the Supplier

Globe Valves vs. Diaphragm Valves: How to Choose?

- Sep 09, 2025

Selection and Application of Globe Valves

- Nov 13, 2025

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/globe-valves-vs-diaphragm-valves-how-to-choose.html