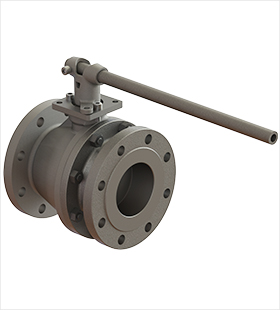

Válvula de bola flotante forjada con cuerpo 2PCS / 3PCS

Key Specifications / Features

Detail Information

Tamaño: 1/2 pulgada - 10 pulgadas

Clase: 150 - 2500 LB

Cuerpo 2PC/3PC Cuerpo de acero forjado

Bola flotante, paso total y reducido

Dispositivo antiestático

Vástago a prueba de reventones

Diseño seguro contra incendios.

Baja emision

Diseño: ASME B16.34/API6D/BS EN ISO 17292 (BS5351)

Cara a cara: ASME B16.10

Extremo a extremo: ASME B16.10

Brida final: ASME B16.5

Extremo BW: ASME B16.25

Prueba: API 598/BS EN 12266 (BS6755)

Prueba de seguridad contra incendios: API 607/API 6FA

Especial: NACE MR0175

| MATERIAL SPECIFICATIONS | |||||

| NO. | PART | A105/ENP | A105/316 | F316/316 | LF2/316 NACE |

| 1 | Body | ASTM A105N | ASTM A105N | ASTM A182-F316 | ASTM A350-LF2 |

| 2 | Adapter | ASTM A105N | ASTM A105N | ASTM A182-F316 | ASTM A350-LF2 |

| 3 | Ball | ASTM A105N/ENP | ASTM A182-F316 | ASTM A182-F316 | ASTM A182-F316 |

| 4 | Seat Ring | PTFE/Nylon/PEEK | PTFE/Nylon/PEEK | PTFE/Nylon/PEEK | PTFE/Nylon/PEEK |

| 5 | Stem | AISI 4140/ENP | ASTM A182-F51 | ASTM A182-F51 | ASTM A182-F51 |

| 6 | Gland Ring | ASTM A276-410 | ASTM A276-316 | ASTM A276-316 | ASTM A276-316 |

| 7 | Body Stud | ASTM A193-B7 | ASTM A193-B7 | ASTM A193-B8 | ASTM A320-L7M |

| 8 | Body Nut | ASTM A194-2H | ASTM A194-2H | ASTM A194-8 | ASTM A194-7M |

| 9 | Steel Ball | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| 10 | Antistatic Spring | Inconel X-750 | Inconel X-750 | Inconel X-750 | Inconel X-750 |

| 11 | Antistatic Spring | Inconel X-750 | Inconel X-750 | Inconel X-750 | Inconel X-750 |

| 12 | Dish Spring | Alloy Steel | Alloy Steel | Alloy Steel | Alloy Steel |

| 13 | Thrust Washer | PTFE | PTFE | PTFE | PTFE |

| 14 | *Gasket | Graphite | Graphite | Graphite | Graphite |

| 15 | *Packing | Graphite | Graphite | Graphite | Graphite |

| 16 | *O-ring | Viton | Viton | Viton | Viton |

| 17 | *O-ring | Viton | Viton | Viton | Viton |

| 18 | Lever Head | Carbon Steel | Carbon Steel | Carbon Steel | Carbon Steel |

| 19 | Lever Pipe | CS Zinc Plated | CS Zinc Plated | CS Zinc Plated | CS Zinc Plated |

| 20 | Lock Plate | Carbon Steel | Carbon Steel | Carbon Steel | Carbon Steel |

| 21 | Nut | Carbon Steel | Carbon Steel | Stainless Steel | Carbon Steel |

| 22 | Screw | Carbon Steel | Carbon Steel | Stainless Steel | Carbon Steel |

| 23 | Pipe | Carbon Steel | Carbon Steel | Stainless Steel | Carbon Steel |

| 24 | Screw | Carbon Steel | Carbon Steel | Stainless Steel | Carbon Steel |

| 25 | Screw | Carbon Steel | Carbon Steel | Stainless Steel | Carbon Steel |

| 26 | Washer | Carbon Steel | Carbon Steel | Stainless Steel | Carbon Steel |

| 27 | Key | Carbon Steel | Carbon Steel | Stainless Steel | Carbon Steel |

| 28 | ** Screw | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| * Recommened Spare Parts ** Locking Washers for 1/2~1-1/2 Screw for 2 & Larger |

|||||

| Full Bore Class 150 | |||||

| Size in | d mm | L mm | H mm | W mm | Weight Kg |

| 1/2 | 13 | 108 | 85 | *160 | 2.8 |

| 3/4 | 19 | 117 | 93 | *160 | 3.7 |

| 1 | 25 | 127 | 112 | *180 | 5.3 |

| 1-1/2 | 38 | 165 | 125 | *240 | 8.3 |

| 2 | 51 | 178 | 126 | 350 | 11.2 |

| 2-1/2 | 64 | 191 | 139 | 400 | 18.4 |

| 3 | 76 | 203 | 164 | 400 | 23 |

| 4 | 102 | 229 | 185 | 450 | 39.3 |

| 6 | 152 | 394 | 270 | **300 | 90 |

| 8 | 203 | 457 | 360 | **400 | 140 |

| 10 | 254 | 533 | 410 | **400 | 230 |

| Full Bore Class 300 | |||||

| Size in | d mm | L mm | H mm | W mm | Weight Kg |

| 1/2 | 13 | 140 | 85 | *160 | 3 |

| 3/4 | 19 | 152 | 93 | *160 | 4 |

| 1 | 25 | 165 | 112 | *180 | 6.6 |

| 1-1/2 | 38 | 190 | 125 | *240 | 12.9 |

| 2 | 51 | 216 | 126 | 400 | 18.9 |

| 2-1/2 | 64 | 241 | 139 | 400 | 28 |

| 3 | 76 | 283 | 166 | 450 | 39 |

| 4 | 102 | 305 | 185 | 500 | 60 |

| 6 | 152 | 403 | 275 | **300 | 130 |

| 8 | 203 | 502 | 360 | **400 | 195 |

| 10 | 254 | 568 | 410 | **400 | 290 |

| Full Bore Class 600 | |||||

| Size in | d mm | L mm | H mm | W mm | Weight Kg |

| 1/2 | 13 | 165 | 85 | *160 | 3.5 |

| 3/4 | 19 | 191 | 93 | *180 | 5 |

| 1 | 25 | 216 | 112 | *240 | 7.5 |

| 1-1/2 | 38 | 241 | 125 | 350 | 15 |

| 2 | 51 | 292 | 130 | 400 | 23 |

| 3 | 76 | 356 | 170 | 500 | 48 |

| 4 | 102 | 432 | 216 | 700 | 80 |

| Full Bore Class 900 | |||||

| Size in | d mm | L mm | H mm | W mm | Weight Kg |

| 1/2 | 13 | 216 | 85 | *160 | 5 |

| 3/4 | 19 | 229 | 93 | *180 | 8 |

| 1 | 25 | 254 | 115 | *240 | 10 |

| 1-1/2 | 38 | 305 | 128 | 400 | 20 |

| 2 | 51 | 368 | 148 | 450 | 25 |

| 3 | 76 | 381 | 196 | 600 | 50 |

| Full Bore Class 1500 | |||||

| Size in | d mm | L mm | H mm | W mm | Weight Kg |

| 1/2 | 13 | 216 | 85 | *160 | 5 |

| 3/4 | 19 | 229 | 112 | *180 | 8 |

| 1 | 25 | 254 | 115 | *240 | 10 |

| 1-1/2 | 38 | 305 | 123 | 400 | 20 |

| 2 | 51 | 368 | 132 | 450 | 30 |

| Full Bore Class 2500 | |||||

| Size in | d mm | L mm | H mm | W mm | Weight Kg |

| 1/2 | 13 | 264 | 93 | *180 | 7.5 |

| 3/4 | 19 | 273 | 96 | *240 | 12 |

| 1 | 25 | 308 | 117 | *350 | 15 |

| 1-1/2 | 38 | 384 | 132 | 450 | 30 |

| 2 | 44 | 451 | 138 | 550 | 37.5 |

| Reduce Bore Class 150 | ||||||

| Size in | d mm | D mm | L mm | H mm | W mm | Weight Kg |

| 3/4*1/2 | 13 | 19 | 117 | 85 | *160 | 3.5 |

| 1*3/4 | 19 | 25 | 127 | 93 | *160 | 5 |

| 1-1/2*1 | 25 | 38 | 165 | 112 | *180 | 7.5 |

| 2*1-1/2 | 38 | 51 | 178 | 125 | *240 | 10 |

| 2-1/2*2 | 51 | 64 | 191 | 126 | 350 | 16 |

| 3*2 | 51 | 76 | 203 | 126 | 350 | 21 |

| 4*3 | 76 | 102 | 229 | 164 | 400 | 35 |

| 6*4 | 102 | 152 | 394 | 185 | 450 | 73 |

| 8*6 | 152 | 203 | 457 | 270 | **300 | 120 |

| 10*8 | 203 | 254 | 533 | 360 | **400 | 200 |

| Reduce Bore Class 300 | ||||||

| Size in | d mm | D mm | L mm | H mm | W mm | Weight Kg |

| 3/4*1/2 | 13 | 19 | 152 | 85 | 160 | *160 |

| 1*3/4 | 19 | 25 | 165 | 93 | 160 | *160 |

| 1-1/2*1 | 25 | 38 | 190 | 112 | 180 | *180 |

| 2*1-1/2 | 38 | 51 | 216 | 125 | 240 | *240 |

| 2-1/2*2 | 51 | 62 | 241 | 126 | 400 | 400 |

| 3*2 | 51 | 76 | 283 | 126 | 400 | 400 |

| 4*3 | 76 | 102 | 305 | 166 | 450 | 450 |

| 6*4 | 102 | 152 | 403 | 185 | 500 | 500 |

| 8*6 | 152 | 203 | 419 | 275 | *300 | **300 |

| 10*8 | 203 | 254 | 457 | 360 | *400 | **400 |

| * Lever Operation ** Gear Operation | ||||||

| Reduce Bore Class 600 | ||||||

| Size in | d mm | D mm | L mm | H mm | W mm | Weight Kg |

| 3/4*1/2 | 13 | 19 | 191 | 85 | *160 | 4 |

| 1*3/4 | 19 | 25 | 216 | 93 | *180 | 5.5 |

| 1-1/2*1 | 25 | 38 | 241 | 112 | *240 | 10.5 |

| 2*1-1/2 | 38 | 51 | 292 | 125 | 350 | 20 |

| 3*2 | 51 | 76 | 356 | 130 | 400 | 29 |

| 4*3 | 76 | 102 | 432 | 170 | 500 | 59 |

| 6*4 | 102 | 152 | 559 | 216 | 700 | 95 |

| Reduce Bore Class 900 | ||||||

| Size in | d mm | D mm | L mm | H mm | W mm | Weight Kg |

| 3/4*1/2 | 13 | 19 | 229 | 85 | *160 | 7 |

| 1*3/4 | 19 | 25 | 254 | 93 | *180 | 9.5 |

| 1-1/2*1 | 25 | 38 | 305 | 115 | *240 | 16.5 |

| 2*1-1/2 | 38 | 51 | 368 | 128 | 400 | 23 |

| 3*2 | 51 | 76 | 381 | 148 | 450 | 42 |

| 4*3 | 76 | 102 | 457 | 196 | 600 | 65 |

| Reduce Bore Class 1500 | ||||||

| Size in | d mm | D mm | L mm | H mm | W mm | Weight Kg |

| 3/4*1/2 | 13 | 19 | 229 | 85 | *160 | 7 |

| 1*3/4 | 19 | 25 | 254 | 112 | *180 | 9.5 |

| 1-1/2*1 | 25 | 38 | 305 | 115 | *240 | 16.5 |

| 2*1-1/2 | 38 | 51 | 368 | 123 | 400 | 23 |

| 3*2 | 51 | 76 | 473 | 132 | 450 | 50 |

| Reduce Bore Class 2500 | ||||||

| Size in | d mm | D mm | L mm | H mm | W mm | Weight Kg |

| 3/4*1/2 | 13 | 19 | 273 | 93 | *180 | 11 |

| 1*3/4 | 19 | 25 | 308 | 96 | *240 | 14 |

| 1-1/2*1 | 25 | 38 | 384 | 117 | *350 | 25 |

| 2*1-1/2 | 38 | 44 | 451 | 132 | 450 | 35 |

| 3*2 | 44 | 64 | 578 | 138 | 550 | 60 |

| * Gear operated | ||||||

Send your message to this supplier

FAQs

¿Qué es una válvula de compuerta con vástago no ascendente?

Es una válvula de compuerta cuyo vástago no se mueve verticalmente, sino que gira internamente para controlar la posición de la compuerta. Ideal para instalaciones con espacio limitado.

¿Cómo funciona una válvula de compuerta con vástago no ascendente?

La rueda manual gira el vástago, moviendo la compuerta hacia arriba o abajo sin cambiar la altura externa del vástago.

¿Cómo funciona una válvula de compuerta con vástago ascendente?

La rueda manual eleva el vástago y la compuerta juntos, proporcionando un indicador visual claro del estado de la válvula.

¿Cuál válvula debo elegir?

Elija una válvula con vástago ascendente para aplicaciones sobre tierra donde se necesite visibilidad y mantenimiento fácil. Elija una válvula con vástago no ascendente para instalaciones subterráneas o con espacio limitado donde el diseño compacto es esencial.

Conclusión

La elección entre una válvula de compuerta con vástago ascendente y una con vástago no ascendente depende de sus necesidades específicas. Si requiere monitoreo visual fácil y mantenimiento, use una de vástago ascendente. Si prioriza el ahorro de espacio y la instalación subterránea, la de vástago no ascendente es mejor.

Nuestras válvulas están diseñadas y fabricadas de acuerdo con normas internacionales como API, ISO, DIN, EN, BS, JIS, GOST y también se pueden personalizar según las especificaciones del cliente.

Disponemos de válvulas de bola y válvulas de mariposa de alto rendimiento con diseño a prueba de fuego, además contamos con válvulas con certificación API 607 y API 6FA.