Full Port vs. Reduced Port Ball Valves: What's the Difference?

Ball valves are essential components in piping systems, allowing for precise control of fluid flow. Among the many types available, full-port and reduced-port ball valves stand out for their distinct designs and applications. Understanding their differences is key to selecting the right valve for your system.

What Is a Full-Port Ball Valve?

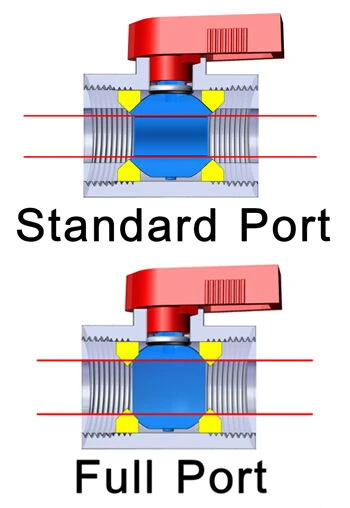

A full-port ball valve, also referred to as a full-bore ball valve, is designed to allow maximum fluid flow with minimal resistance. Its defining feature is its internal bore, which matches the diameter of the connected pipe. This seamless flow path minimizes pressure drops, making the full-port ball valve ideal for applications requiring high flow efficiency and reduced turbulence.

Key Advantages of Full-Port Ball Valves

1. Minimal Pressure Loss

The unrestricted flow path ensures that pressure drops are negligible, which is crucial for systems handling viscous fluids or requiring high flow rates.2. Reduced Energy Consumption

In applications where pumping power is needed, the minimal pressure loss of a full-port valve translates to energy savings.3. Versatile Applications

Full-port ball valves are widely used across industries such as:Oil and Gas

For managing high-pressure pipelines and minimizing energy loss.

Water Treatment

To maintain consistent flow in filtration systems.

Petrochemical

For precise handling of hazardous chemicals.

Food Processing

Where cleanliness and efficient flow are critical.

Construction

For concrete mixing and slurry transportation.

When to Choose a Full-Port Ball Valve

If your system prioritizes high flow efficiency and cannot afford significant pressure drops, a full-port ball valve is the ideal choice. Applications include high-capacity pipelines, systems dealing with viscous or abrasive fluids, and processes where efficiency directly impacts operational costs.

What Is a Reduced-Port Ball Valve?

A reduced-port ball valve, also known as a standard-port or reduced-bore valve, has a smaller internal diameter compared to the connected pipe. Typically, the valve’s bore size is one pipe size smaller than the pipe it connects to. For instance, a 1-inch reduced-port valve may have a ¾-inch bore.

This smaller bore introduces a degree of flow restriction, resulting in increased pressure drops compared to full-port ball valves. However, reduced-port valves are still effective in many applications where full flow is not critical.

This smaller bore introduces a degree of flow restriction, resulting in increased pressure drops compared to full-port ball valves. However, reduced-port valves are still effective in many applications where full flow is not critical.

Key Features of Reduced-Port Ball Valve

Compact Design

Reduced-port valves are generally smaller and lighter, making them suitable for systems with space constraints.

Cost-Effectiveness

These valves are more affordable than full-port alternatives, making them a practical choice for less demanding applications.

Sufficient for Low-Flow System

In situations where high flow rates aren’t essential, reduced-port valves offer adequate performance without unnecessary expense.

Common Applications for Reduced-Port Ball Valves

Tanks and Dispensers

Ideal for controlling flow in storage systems or dispensing units.

Portable Equipment

Often used in smaller, lightweight systems where compactness is an advantage.

Light Industrial Use

Suitable for non-critical processes where some pressure drop is acceptable, such as air or low-pressure water lines.

For systems with moderate flow needs, a reduced-port valve is a cost-effective alternative.

Reduced-port valves are suitable for systems that can tolerate some pressure loss.

Reduced-port valves are smaller, lighter, and more affordable, making them ideal for budget-conscious or compact systems.

By understanding the unique advantages and applications of each type, you can make an informed decision that ensures optimal performance and cost-effectiveness for your operations. Whether you’re managing a complex industrial pipeline or a simple dispensing unit, selecting the right ball valve is a crucial step in achieving operational success.

When to Use a Reduced-Port Ball Valve

Choose a reduced-port ball valve when cost savings, compact design, or moderate flow capacity meets your system requirements. These valves excel in scenarios where pressure drops are tolerable and high flow efficiency is not a priority.Comparing Full-Port and Reduced-Port Ball Valves

| Feature | Full-Port Ball Valve | Reduced-Port Ball Valve |

| Internal Bore Size | Matches pipe diameter | Smaller than pipe diameter |

| Flow Efficiency | Maximum (minimal restriction) | Moderate (some restriction) |

| Pressure Drop | Negligible | Higher |

| Applications | High-flow, critical systems | Low-flow, non-critical systems |

| Cost | Higher | Lower |

| Size and Weight | Larger and heavier | Smaller and lighter |

Choosing the Right Ball Valve for Your Needs

When selecting between full-port and reduced-port ball valves, consider the following factors:1. Flow Requirements

For systems that require high flow rates and minimal pressure drops, opt for a full-port ball valve.For systems with moderate flow needs, a reduced-port valve is a cost-effective alternative.

2. Pressure Considerations

Full-port valves are better for systems where pressure consistency is critical.Reduced-port valves are suitable for systems that can tolerate some pressure loss.

3. Budget and Space Constraints

Full-port valves may have higher upfront costs but save on operational energy costs.Reduced-port valves are smaller, lighter, and more affordable, making them ideal for budget-conscious or compact systems.

4. Industry Standards

Some industries, like petrochemical or food processing, require full-port valves to meet specific regulatory or efficiency standards.Conclusion

The choice between full-port and reduced-port ball valves ultimately depends on the specific needs of your system. While full-port valves excel in high-flow, efficiency-driven applications, reduced-port valves provide a practical solution for cost-sensitive and space-limited environments.By understanding the unique advantages and applications of each type, you can make an informed decision that ensures optimal performance and cost-effectiveness for your operations. Whether you’re managing a complex industrial pipeline or a simple dispensing unit, selecting the right ball valve is a crucial step in achieving operational success.

Send your message to this supplier

topper

- www.chinatopper.com

- Address: Xiamen

- Phone: 86-592-5819200

- Business Type: Trading, Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.mfrsvalve.com/news/full-port-vs-reduced-port-ball-valves-what-s-the-difference.html