Control Valve Plugs: Core Component of Industrial Automation

In the field of industrial automation, control valves play a crucial role, and the valve plug is the core component of a control valve. The valve plug is not only the movable part of the control valve but also the key element for achieving fluid control. It fits tightly with the valve seat, capable of shutting off fluid and regulating the flow by changing the throttling area, thereby achieving precise process control. The design, material selection, and processing of the valve plug directly determine the performance, reliability, and application range of the control valve. This article will explore the various characteristics, design types, and performance of control valve plugs in practical industrial applications.

Importance of the Valve Plug

The valve plug is the core component of a control valve. Working together with the valve seat, it can tightly close and cut off fluid, ensuring complete blockage when needed. At the same time, the valve plug regulates the fluid flow by changing the throttling area, achieving precise control over industrial processes.

The shape of the valve plug (or the sleeve opening shape in cage-type valves) determines the flow characteristics of the control valve, such as linear, equal percentage, quick-opening, and parabolic characteristics. These characteristics directly affect the valve's performance under different operating conditions.

The size of the valve plug and seat, as well as the internal flow path, determine the maximum flow capacity of the control valve. In practical applications, the control valve must be selected with appropriate flow capacity according to different process requirements to ensure system efficiency and stability. Additionally, the material selection and processing of the valve plug and seat determine the operational applicability and reliability of the control valve. Different operating conditions impose different requirements on corrosion resistance, wear resistance, and cavitation resistance. For example, in high-pressure, high-temperature, or corrosive environments, the valve plug must use special materials and processes to ensure long-term stable operation.

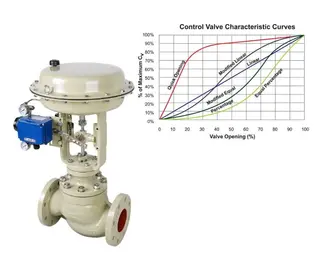

Flow Characteristics of Valve Plugs

The flow characteristic of a valve plug is an important parameter in control valve design. It determines the relationship between flow and valve opening, thereby affecting the regulating performance of the valve. Common flow characteristics include linear, equal percentage, parabolic, and quick-opening.

1. Linear Flow Characteristic

A linear flow characteristic means that the relative flow of the valve is directly proportional to its relative displacement (stroke). That is, the flow change per unit displacement is constant. At small openings, the flow changes significantly and sensitivity is high, but control can be difficult and may even cause oscillation. At large openings, the relative flow change is small, making regulation slow and less timely. Linear characteristics are suitable for applications requiring relatively stable flow changes but require precise control systems to avoid oscillation.

2. Equal Percentage Flow Characteristic

Equal percentage flow characteristic means that the relative flow change per unit relative stroke is proportional to the relative flow at that point. The curve slope increases with increasing stroke, also called logarithmic flow characteristic. This characteristic provides small flow changes at low openings for smooth regulation, and large flow changes at high openings for sensitive and effective control. Equal percentage characteristics are suitable for applications requiring precise regulation over a wide range, offering better controlling performance.

3. Parabolic Flow Characteristic

Parabolic flow characteristic means that the relative flow change per unit relative stroke is proportional to the square root of the relative flow at that point. This characteristic is designed to compensate for the poor regulation effect of linear characteristics at small openings. Parabolic characteristics provide moderate flow changes at small openings for smooth control, and large flow changes at large openings for sensitive and effective regulation. However, most manufacturers do not offer parabolic valve plugs as standard products because they require more complex design and manufacturing processes.

4. Quick-Opening Flow Characteristic

Quick-opening flow characteristics provide a large flow even at small openings, and flow quickly reaches maximum as the opening increases. Further increases in opening result in minimal flow change. Quick-opening characteristics are commonly used in on-off control valves, achieving significant flow at small openings. This is suitable for applications requiring rapid opening and closing, allowing the system to respond quickly.

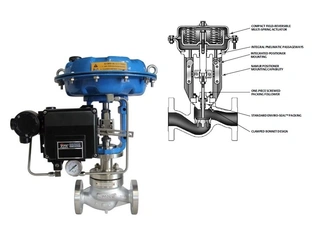

Structural Design of Valve Plugs

To achieve different valve characteristics, valve plug designs vary widely and are generally divided into linear-stroke and rotary-stroke types. Different designs are suited for different operating conditions and control requirements.

1. Linear-Stroke Valve Plugs

Linear-stroke plugs change the flow area with vertical movement relative to the valve seat. Common types include piston-type plugs, sleeve-type plugs, needle or cylindrical slotted plugs, multi-stage plugs, and specially designed plugs.

Piston-Type Valve Plug

The piston-type plug was widely used in early control valves. It features a simple structure and good sealing performance, but has drawbacks such as high unbalanced force, lower flow capacity, and higher noise. To address these issues, some foreign manufacturers began developing sleeve-type control valves in the 1960s.

Sleeve-Type Valve Plug

Sleeve-type plugs adjust flow by moving the sleeve vertically. Compared to piston-type plugs, sleeve plugs have lower tight shut-off and higher leakage. In industrial use, sleeves wear easily, shut-off is not tight, leakage increases, and functional safety may be insufficient. The sleeve valve structure and flow path are more complex than piston types, with more components and maintenance requirements. Seals are numerous and often wear-prone, such as extrusion-resistant seals or spring-loaded sealing rings, requiring frequent replacement. Special gaskets are expensive, increasing maintenance costs. Quick-disassembly designs in sleeve valves address durability and frequent maintenance issues.

Drilled Cage-Type Valve Plug

Drilled cage-type plugs are designed for high-pressure drop applications, effectively preventing cavitation, noise, corrosion, and vibration. Flow characteristics are controlled via hole distribution. Minimum controllable Cv is determined by the gap between the plug and cage and the distance from the sealing surface to the bottom of the cage holes. This plug type is suitable for stable operation under high-pressure drops, providing reliable control performance.

2. Rotary-Stroke Valve Plugs

Rotary-stroke plugs adjust the flow area by rotation. They feature simple structures and fast response, suitable for quick on-off applications. Flow characteristics can be modified by changing plug shape and opening design to meet different control requirements.

Balanced Valve Plugs

To address high unbalanced forces in single-seat valves, balanced valve plugs are used. These plugs have balance holes that channel fluid pressure to a balancing chamber on the other side of the plug, isolated from the outlet flow path. This balances most pressure differences, leaving only the force equivalent to fluid pressure on the stem cross-section. Since the balance holes are small, clogging eliminates the balance effect, so balanced plugs are unsuitable for dirty media or those containing large solid particles or prone to crystallization. Typically, the balancing chamber is fixed, with sealing rings installed on the plug, which moves like a piston.

Material Selection and Processing of Valve Plugs

Material selection and processing directly determine the operational reliability and applicability of control valves. Different conditions require varying corrosion resistance, wear resistance, and cavitation resistance. In high-pressure, high-temperature, or corrosive environments, special materials and processes are necessary for long-term stability.

1. Valve Plug Material Selection

Valve plug materials should match the operating conditions. Common materials include stainless steel, alloy steel, and hard alloys. Stainless steel offers good corrosion resistance and mechanical properties, suitable for general industrial environments. Alloy steel provides higher strength and wear resistance, suitable for high-pressure, high-temperature harsh conditions. Hard alloys have extremely high hardness and wear resistance, ideal for highly abrasive applications.

2. Valve Plug Processing

Processing includes surface and heat treatments. Surface treatment enhances corrosion and wear resistance, such as hard chrome plating or ceramic coating. Heat treatment improves strength and toughness, ensuring stability in high-pressure, high-temperature, or harsh environments.

Practical Considerations in Application

In practical applications, selecting the appropriate valve plug type and flow characteristic requires a comprehensive evaluation of process requirements, operating conditions, and maintenance costs. For example, in scenarios requiring rapid on-off operation, an angular-stroke valve plug with a quick-opening flow characteristic may be preferred; whereas in cases demanding precise regulation, a linear-stroke valve plug with an equal-percentage flow characteristic is more suitable.

It is also essential to pay attention to the material selection and manufacturing process of the valve plug to ensure its reliability and stability under actual operating conditions.

Furthermore, regular maintenance and inspection are crucial for ensuring the long-term stable operation of control valves. For wear-prone components, such as the sealing elements of sleeve valves, periodic replacement is necessary to prevent leaks and functional failures caused by damaged parts. For valve assemblies with complex internal structures, designs that allow quick disassembly are recommended to facilitate maintenance and repair.

Conclusion

The valve plug is the core component of a control valve, and its design, material selection, and manufacturing process directly determine the valve's performance, reliability, and scope of application. By properly selecting the valve plug type and flow characteristic, the control requirements of different industrial scenarios can be met. Additionally, attention to material choice, processing methods, and regular maintenance and inspection ensures long-term stable operation under real-world conditions. As industrial automation advances, the valve plug, as the heart of the control valve, will continue to play an indispensable role.

Send your message to this supplier

Related Articles from the Supplier

How to Choose the Right Control Valve

- Jan 12, 2026

Control Valve Leakage Classes Explained

- Jan 29, 2026

What is Diaphragm Type Pneumatic Control Valve

- Jan 24, 2026

Flow Characteristics of Control Valves

- Oct 14, 2025

Crane Valves for Fluid Control Systems

- Dec 14, 2024

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/control-valve-plugs-core-component-of-industrial-automation.html