Filter Layers vs. Backwashing Frequency in Shallow Sand Filters

In the field of water treatment, shallow sand filters are widely used filtration devices whose performance and operational efficiency are influenced by numerous factors. Among these factors, the relationship between the number of filter layers and backwashing frequency is particularly critical. This paper will delve into the impact of the number of filter layers on the backwashing frequency of shallow sand filters and explore how to optimize this choice based on different application scenarios, aiming to provide valuable references for practitioners in the field.

The Basic Relationship between Filter Layers and Backwashing Frequency

The number of filter layers in a shallow sand filter has a direct and significant impact on backwashing frequency. Different configurations of filter layers lead to varying filtration effects and backwashing requirements. To better understand this relationship, we can analyze two common scenarios: single-layer filters and multi-layer filters.

1. Backwashing Frequency of Single-Layer Filters

Single-layer filter shallow sand filters are commonly used in practice. These filters have relatively large pore sizes, which means they can accommodate a limited amount of impurities. When the raw water contains a high concentration of impurities, the filter layer can become clogged quickly. This clogging leads to a decrease in filtration efficiency and a rapid increase in the pressure differential during the filtration process. To maintain the normal operation of the filter, more frequent backwashing operations are required to remove impurities from the filter layer and restore filtration functionality.

However, single-layer filters also have their unique advantages. Due to the relatively uniform grain size of the filter material, backwashing water can more easily penetrate the filter layer and flush out impurities. Therefore, although the backwashing frequency is higher, the duration of each backwash is relatively short. This characteristic makes single-layer filter shallow sand filters operate more efficiently when dealing with raw water that has a low concentration of impurities.

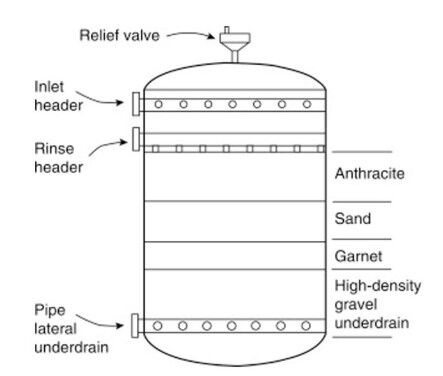

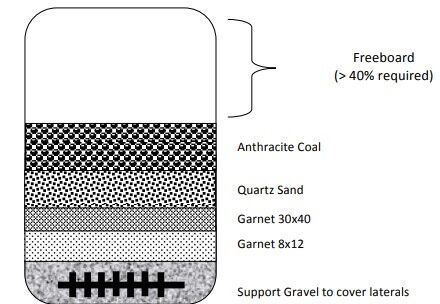

2. Backwashing Frequency of Double-Layer or Multi-Layer Filters

Unlike single-layer filters, shallow sand filters with double or multiple layers of filter material create a more complex filtration structure by using filter materials with different grain sizes and densities. The advantage of this structure is that the upper layer of filter material can intercept larger particles, while the lower layer can capture finer particles. This stratified interception significantly enhances the filter's capacity to hold impurities, allowing it to accommodate more contaminants without becoming quickly clogged. As a result, the filtration cycle is extended, and the backwashing frequency is correspondingly reduced.

However, the backwashing effect for double or multi-layer filters is relatively complex. Due to the non-uniform grain size of the filter material, backwashing water requires greater intensity to effectively penetrate the filter layer. Additionally, the design of backwashing time and intensity becomes even more critical. If the backwashing design is not reasonable, incomplete backwashing may occur, leading to clogging of the filter layer. In such cases, the backwashing frequency may not only fail to decrease but could actually increase due to frequent clogging.

Other Factors Affecting Backwashing Frequency

The number of filter layers is just one of the many factors that influence backwashing frequency. In reality, backwashing frequency is also affected by a combination of other factors, including raw water quality, physical properties of the filter material, filtration speed, and backwashing design.

1. Raw Water Quality

Raw water quality is one of the important factors affecting backwashing frequency. If the turbidity of the raw water is high and it contains a large amount of impurities, even a filter with double or multiple layers of filter material may have a high backwashing frequency. This is because a large quantity of impurities can quickly fill the pores of the filter layer, leading to a decrease in filtration efficiency. Therefore, when designing and operating shallow sand filters, it is essential to fully consider the characteristics of the raw water quality to reasonably select the number of filter layers and backwashing parameters.

2. Filter Grain Size and Uniformity Coefficient

The grain size and uniformity coefficient of the filter material also have a significant impact on backwashing frequency. Generally, the smaller the grain size and the larger the uniformity coefficient, the stronger the filter layer's capacity to hold impurities. This means that the filter can accommodate more contaminants without becoming quickly clogged, thereby reducing backwashing frequency. However, excessively small grain size and high uniformity coefficient can also pose some problems. For example, the difficulty of backwashing increases, requiring higher backwashing intensity and longer backwashing time to thoroughly remove impurities from the filter layer. Therefore, when selecting filter material, it is necessary to balance the capacity to hold impurities with the difficulty of backwashing.

3. Filtration Speed

Filtration speed is an important factor affecting the load on the filter layer. The higher the filtration speed, the greater the volume of water the filter layer needs to process, and the higher the load. Under such circumstances, the filter layer is more prone to clogging, and the backwashing frequency will correspondingly increase. Therefore, when designing a filter, it is necessary to reasonably control the filtration speed to balance filtration efficiency and backwashing frequency. Excessively high filtration speed, although it can improve filtration efficiency, will increase backwashing frequency and operating costs. On the other hand, excessively low filtration speed may lead to insufficient treatment capacity of the filter, failing to meet actual needs.

4. Backwashing Intensity and Duration

Reasonable backwashing intensity and duration are key to ensuring effective backwashing. If the backwashing intensity is insufficient or the duration is too short, impurities in the filter layer cannot be completely removed, leading to clogging of the filter layer and increased backwashing frequency. Conversely, if the backwashing intensity is too high or the duration is too long, not only will it waste water resources and energy, but it may also cause unnecessary impact and wear on the filter layer. Therefore, it is necessary to design the backwashing intensity and duration reasonably based on factors such as the characteristics of the filter material and the quality of the raw water to ensure effective backwashing and extend the filtration cycle.

Selection of Filter Layers for Different Application Scenarios

In practical applications, the selection of the appropriate number of filter layers requires a comprehensive consideration of various factors, including raw water quality, filtration precision requirements, equipment cost, and the complexity of operation and maintenance. Different application scenarios have different requirements for the performance and economy of the filter, so it is necessary to make optimized choices based on specific situations.

1. Scenarios with Good Water Quality

If the raw water quality is good and contains few impurities, a single-layer filter shallow sand filter can be considered. In this case, although the backwashing frequency may be higher, the backwashing cycle can still be relatively long due to the low concentration of impurities in the raw water. Moreover, single-layer filter filters have lower equipment costs and simpler backwashing designs, which can reduce operating costs and maintenance complexity. Therefore, when treating raw water with good quality, a single-layer filter filter is a more economical and practical choice.

2. Scenarios with Poor Water Quality

For scenarios where the raw water has high turbidity and a large amount of impurities, it is recommended to use a shallow sand filter with double or multiple layers of filter material. Although the equipment cost and backwashing design requirements are higher, filters with double or multiple layers of filter material can significantly enhance the capacity to hold impurities, reduce backwashing frequency, and thereby improve the operational efficiency and economy of the filter. In these scenarios, rational filter layer design and optimization of backwashing parameters are crucial to effectively extend the filtration cycle, reduce the number of backwashes, and lower operating costs.

The Importance of Optimizing Backwashing Design

Regardless of whether single or multi-layer filter material is used in shallow sand filters, rational backwashing design is key to ensuring the efficient operation of the filter. The more filter layers there are, the stronger the capacity to hold impurities, the lower the backwashing frequency, but the higher the backwashing design requirements. In practical applications, the optimal backwashing parameters, including backwashing intensity, duration, and water flow direction, can be determined through experiments or empirical data. For example, for filters with double or multiple layers of filter material, a stratified backwashing method can be adopted, first backwashing the upper layer of filter material and then the lower layer, to ensure effective backwashing. Additionally, backwashing parameters can be dynamically adjusted according to changes in raw water quality to adapt to different operating conditions.

Conclusion

In summary, the number of filter layers has a significant impact on the backwashing frequency of shallow sand filters. Filters with single-layer filter material have higher backwashing frequency but shorter backwashing duration; filters with double or multiple layers of filter material have lower backwashing frequency but higher backwashing design requirements. In addition, factors such as raw water quality, filter grain size and uniformity coefficient, filtration speed, and backwashing intensity and duration also have an important impact on backwashing frequency. In practical applications, it is necessary to comprehensively consider factors such as raw water quality, filtration precision requirements, and equipment cost to select the appropriate number of filter layers and backwashing parameters to achieve the best filtration effect and operational efficiency. Through rational selection of filter material and backwashing design, the backwashing frequency can be effectively reduced, and the operational efficiency and economy of shallow sand filters can be improved, providing strong support for the development of the water treatment industry.

Send your message to this supplier

Related Articles from the Supplier

How to Arrange Filter Layer for Quartz Sand Filters?

- Aug 21, 2025

Multimedia Filter Media Combination Selection Guide

- Nov 29, 2024

Related Articles from China Manufacturers

The Finish Treatment Of Filter Bag

- Aug 04, 2018

Knowledge of a filter

- May 25, 2018

Filter Clogging Analysis and Its Solutions

- Nov 04, 2025

Brief introduction of filter separator

- Mar 19, 2018

Related Products Mentioned in the Article

Supplier Website

Source: https://www.fabtank.com/news/filter-layers-vs-backwashing-frequency-in-shallow-sand-filters.html