Solutions for Diesel Generator Oil Contamination by Water

Diesel generators are crucial power equipment used extensively across various industries, including manufacturing, commercial, construction, and more, providing stable power during outages or in areas without access to a consistent power supply. As these generators accumulate operational hours, it is inevitable that they will experience different types of faults. One of the most common and impactful issues is water contamination in the engine oil. The presence of water in engine oil can severely affect the lubrication system, increase wear and tear on components, and even lead to complete engine failure. Therefore, timely detection and resolution of oil contamination is essential to ensuring the diesel generator operates effectively.

Manifestation of Water Contamination in Diesel Generator Oil

Water contamination in engine oil can either be detected immediately during startup or may gradually manifest over an extended operational period. Recognizing the signs of water contamination early helps in preventing the issue from escalating into a more serious problem.

1. Increased Oil Level

When water accumulates in the engine oil, it causes the oil level to rise. Typically, the oil level remains within the specified range, but excessive water content will cause a noticeable increase in the oil level. The most straightforward method of checking the oil level is by using the dipstick. If the oil level is higher than normal, it indicates the presence of water, which calls for further investigation.

2. Change in Oil Appearance

The appearance of the engine oil is a crucial indicator of water contamination. Under normal conditions, the oil should be clear, transparent, and possess a golden or amber hue, with a proper viscosity and lubrication properties. However, when water enters the oil, it causes a change in color. The oil may appear milky white, gray, or brown, and its texture becomes more viscous, losing its normal flow characteristics. Additionally, emulsified oil may form white foam, which is another telltale sign of water contamination.

3. Emulsification of Oil

Emulsification occurs when water mixes with the engine oil, creating a thick, cream-like consistency. This mixture significantly reduces the oil's ability to lubricate the engine components, which affects the engine's performance. If emulsification occurs, the oil will not provide adequate lubrication, accelerating component wear and potentially damaging the oil pump. Prolonged emulsification of the oil leads to poor engine efficiency and can eventually result in complete engine failure.

Causes of Water Contamination in Diesel Generator Oil

Water contamination in engine oil can arise from both external sources and internal leaks. Understanding the root causes of this issue is essential for effective troubleshooting and repair.

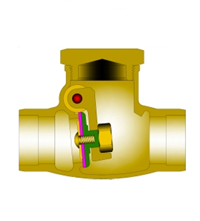

1. Faulty Oil Cooler

The oil cooler is responsible for maintaining the oil temperature within a specified range by transferring heat away from the oil. If the oil cooler fails, particularly due to cracks in the cooler's pipes or loose connections, cooling water can seep into the cooler and come into contact with the engine oil. This results in water contamination of the oil. This is one of the most common causes of water intrusion in diesel generator oil.

Furthermore, dirt, deposits, or scale buildup inside the cooler can cause blockages, affecting the oil cooler's functionality. As a result, coolant water may leak into the engine oil, leading to oil contamination and reduced cooling efficiency, which increases the risk of engine overheating.

2. Water Plug or Passage Leaks

The water plugs and water passage system in diesel generators are responsible for circulating coolant water to maintain the engine's temperature. Water plugs are specifically designed to seal the coolant passages to prevent leakage. Over time, however, these plugs may deteriorate due to aging or corrosion, causing cracks or deformities that allow coolant water to seep through. When coolant leaks into the oil passage, it leads to the presence of water in the engine oil.

Leaks in the water passages, another common cause of water contamination, allow water to enter the oil passages and mix with the oil, resulting in water contamination. This issue can be particularly damaging as it often goes unnoticed for extended periods, leading to severe engine performance issues.

3. Damaged Cylinder Liner Seals

Cylinder liner seals are critical components in the engine that prevent coolant water from mixing with the engine oil. If these seals become damaged or wear out, coolant can leak into the oil passage through the cylinder liners. This issue is more likely to occur under high-temperature and high-pressure conditions, where the seals are subject to greater stress, leading to premature wear or aging.

The main reasons for the deterioration of cylinder liner seals include poor-quality coolant, improper maintenance of the cooling system, and extreme temperature or pressure conditions. To avoid such issues, regular inspection and timely replacement of these seals are necessary, especially in generators that operate under heavy load conditions.

4. Damaged Cylinder Head Gasket

The cylinder head gasket is an essential sealing element that separates the combustion chamber from the oil and coolant passages. It prevents coolant or oil from mixing with the gases in the combustion chamber. Over time, the cylinder head gasket may degrade due to high temperatures, excessive load, or poor-quality coolant, causing cracks or hardness. This degradation leads to coolant leakage into the engine oil, resulting in water contamination.

Cylinder head gasket failure is often caused by long-term overloading of the engine, excessive cooling system pressure, or poor-quality coolant. Therefore, regular inspection and timely replacement of the gasket are critical to preventing this type of contamination.

5. Cracked Cylinder Liners

The cylinder liner, which directly contacts the coolant, is another component prone to cracking over time. This is especially true when temperature variations cause thermal stresses on the engine. A cracked cylinder liner allows coolant to seep into the oil passages, resulting in water contamination in the engine oil.

Cylinder liner cracks are typically caused by external climate factors, defects in the cooling system, or excessive engine fatigue. These cracks can lead to severe engine damage if not detected and repaired promptly.

Dangers of Water Contamination in Diesel Generator Oil

The introduction of water into the engine oil can have several adverse effects on the diesel generator's operation. Understanding the potential consequences helps in recognizing the severity of the issue and emphasizes the need for prompt corrective action.

1. Reduced Lubrication Performance

The primary function of engine oil is to lubricate the engine components, reducing friction and wear. When water enters the oil, it disrupts this lubrication, leading to emulsification. Emulsified oil loses its ability to effectively reduce friction, resulting in increased wear on mechanical parts and accelerating engine failure.

2. Corrosion

Water contamination in the engine oil reacts with the additives and metal surfaces in the engine, generating acidic substances. These acids can cause corrosion on the internal components, leading to rust and the eventual degradation of engine parts. In high-temperature environments, the chemical reaction between water and oil intensifies, further accelerating the corrosion process and shortening the engine's lifespan.

3. Engine Failure

Water contamination not only affects the lubrication performance but also causes overheating, incomplete combustion, and increased exhaust emissions. In severe cases, the presence of water can damage the oil pump, the engine block, and other critical components, potentially leading to complete engine failure. As water contamination is one of the leading causes of diesel generator failure, addressing this issue is crucial for maintaining long-term reliability.

Measures to Prevent Water Contamination in Diesel Generator Oil

To prevent and resolve water contamination in diesel generator oil, a series of effective maintenance and repair strategies must be implemented.

1. Regular Inspection and Maintenance

Routine checks of the oil's appearance, oil level, and signs of emulsification are essential for early detection of water contamination. By regularly inspecting the dipstick for oil level abnormalities, operators can identify rising oil levels caused by water accumulation. If emulsified or discolored oil is detected, an immediate oil change should be conducted, followed by a search for the source of contamination.

Additionally, it is critical to routinely inspect essential components such as the oil cooler, cylinder liner seals, and cylinder head gaskets to ensure they are in good working condition, thereby reducing the risk of water intrusion.

2. Cooling System Maintenance

The cooling system plays a key role in ensuring the diesel generator's optimal performance. Regular maintenance of components like the coolant passages, oil cooler, and water pump is necessary to prevent water contamination. Proper attention should be paid to the quality of coolant and the operating temperature to avoid any failure in the cooling system that could lead to oil contamination.

3. Replacing Seals and Gaskets

Timely inspection and replacement of critical seals, such as the cylinder liner seals and cylinder head gasket, are vital to preventing water from entering the engine oil system. Diesel generators operating under heavy load conditions should undergo frequent checks of these components to avoid potential contamination.

4. Using High-Quality Engine Oil

Using high-quality engine oil can significantly reduce the impact of water contamination. Premium oils have better emulsification resistance, meaning they can perform longer even in the presence of small amounts of water. Regular oil changes and maintaining clean oil help ensure the continued longevity of the engine.

Conclusion

Water contamination in diesel generator oil is a common yet serious issue that can lead to significant engine performance degradation and failure. By conducting regular inspections and maintaining essential components like the oil cooler, seals, and gaskets, operators can prevent or minimize the impact of water contamination. Using high-quality oil and ensuring the cooling system is in top condition further reduces the risk of contamination. By addressing water contamination proactively, diesel generator reliability and longevity are enhanced, ensuring continuous and efficient power supply in critical operations.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

L80-13Cr Oil Piping for Australian Client

- Aug 22, 2016

Working Principle of Solenoid Valve for Water

- Jul 28, 2020

Asia's oil import volume will double by 2035

- Sep 17, 2014

Industrial demand for oil casings

- Feb 16, 2017

Related Products Mentioned in the Article

- www.chinatopper.com

- Address: Xiamen

- Phone: 86-592-5819200

- Business Type: Trading, Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.chinageneratorsets.com/news/solutions-for-diesel-generator-oil-contamination-by-water.html