Compression Ignition Method of Diesel Generator Sets

In today's society, electricity has become an indispensable part of our lives. Whether in households, factories, or large-scale construction projects, a stable power supply is crucial for normal operations. However, in certain situations, such as remote areas, temporary construction sites, or emergency backup power, conventional grid supply may not meet the demand. In these cases, diesel generator sets become an ideal solution. Today, we will take an in-depth look at the compression ignition method of diesel generator sets and explore how it achieves efficient, economical, stable, and environmentally friendly power generation.

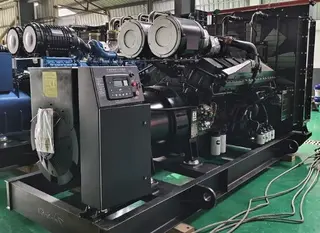

Introduction to Diesel Generator Sets

A diesel generator set is a power generation device that uses diesel as fuel. It generates power by burning diesel, which then drives the generator to produce electricity. Due to its high power output and high generation efficiency, it is widely used in scenarios requiring high reliability and high-efficiency power generation, such as large vehicles, heavy-duty construction vehicles, ships, and power stations. These scenarios often have substantial power demands and require extremely stable power supply. Diesel generator sets can meet these demands well, providing stable electricity for various complex operating conditions.

Principle of Compression Ignition

The compression ignition method is one of the core technologies of diesel generator sets. Its working principle involves compressing air, then injecting fuel into the cylinder through a high-pressure nozzle. The high temperature and high-pressure environment in the cylinder cause the fuel to ignite spontaneously, thus driving the engine.

Specifically, as the piston moves upward in the cylinder, the air inside is compressed, causing the temperature and pressure to rise. When the temperature and pressure reach the auto-ignition point of diesel (about 220°C), the diesel ignites spontaneously, producing explosive pressure that pushes the piston to move quickly and linearly inside the cylinder. This series of processes constitutes a complete working cycle, including intake, compression, combustion, and exhaust. To maintain continuous engine operation, this working cycle repeats continuously.

Characteristics of the Compression Ignition Method

The compression ignition method features high efficiency, economy, stability, and low emissions. These characteristics make diesel generator sets stand out among many power generation devices and become the first choice for many users.

1. High Efficiency

The compression ignition method allows fuel to burn more completely under high temperature and high pressure, releasing more energy and achieving higher power. Compared with traditional ignition methods, compression ignition can utilize fuel more effectively and improve engine thermal efficiency. This means that with the same fuel consumption, a diesel generator set can generate more electricity, increasing generation efficiency.

2. Economy

Because fuel burns more completely, diesel generator sets consume relatively less fuel during operation. This not only reduces operating costs but also reduces fuel waste. Additionally, the high stability of compression ignition prevents sudden shutdowns or stalling, reducing maintenance frequency and further lowering usage costs.

3. Stability

Compression ignition offers very high stability. During operation, the generator can maintain efficient, precise, and stable performance. This is because compression ignition does not rely on an external ignition source but uses the high temperature and pressure in the cylinder to ignite the fuel. This ignition method stabilizes the combustion process and reduces the chance of incomplete combustion or engine stalling. Therefore, diesel generator sets can operate stably under various complex conditions, providing reliable power supply.

4. Low Emissions

Compression ignition allows fuel to burn more completely, reducing unburned fuel and harmful gas emissions. Compared with traditional ignition methods, compression ignition produces relatively lower emissions, especially nitrogen oxides (NOx) and particulate matter. This makes diesel generator sets more environmentally friendly and compliant with modern environmental protection requirements.

Working Process of Compression Ignition

The working process of compression ignition mainly consists of four stages: fuel injection, compression, combustion, and exhaust. Below is a detailed analysis of each stage's principle and characteristics.

1. Fuel Injection Stage

During the fuel injection stage, the high-pressure fuel pump injects a certain amount of fuel into the cylinder. The fuel forms fine droplets through the high-pressure nozzle, quickly mixing with the air in the cylinder. This process is critical, as the atomization quality directly affects combustion efficiency. Good atomization ensures thorough mixing of fuel and air, improving combustion efficiency.

2. Compression Stage

After the fuel is injected into the cylinder, the piston begins to move upward, compressing the mixture in the cylinder. During this process, the temperature and pressure inside the cylinder continue to rise. When the temperature and pressure reach the diesel's auto-ignition point, the fuel begins to ignite. The compression ratio in this stage is very important, as it determines whether the temperature and pressure in the cylinder can reach the diesel's auto-ignition point. Diesel engines generally have a higher compression ratio than gasoline engines to achieve higher combustion efficiency and thermal efficiency.

3. Combustion Stage

During the combustion stage, as the temperature and pressure rise, the mixture reaches its ignition temperature and combustion occurs spontaneously. The high-temperature, high-pressure gas pushes the piston downward, outputting power. This stage is critical because it directly determines the engine's power and efficiency. Compression ignition ensures a more stable and efficient combustion process, reducing the likelihood of incomplete combustion.

4. Exhaust Stage

After combustion, exhaust gases need to be expelled from the cylinder to prepare for the next cycle. During the exhaust stage, the exhaust valve opens, and the gases are discharged through the exhaust pipe. Exhaust efficiency in this stage is also important, as it directly affects engine performance and emissions. An efficient exhaust system reduces residual gases in the cylinder, improving engine efficiency and environmental performance.

Diesel vs. Gasoline Generator Ignition Methods

Although diesel and gasoline generator sets are both common, they differ in ignition methods and performance. Below is a comparison of diesel and gasoline generator sets from several aspects.

1. Ignition Method

Diesel generators use compression ignition, while gasoline generators generally use spark ignition. Compression ignition relies on high temperature and pressure in the cylinder for fuel self-ignition, whereas spark ignition requires a spark plug. This difference leads to significant performance and application variations between diesel and gasoline generators.

2. Fuel Characteristics

Diesel has a relatively low auto-ignition temperature (about 220°C), high viscosity, and is difficult to vaporize, while gasoline has a low flash point (<28°C) and is highly volatile. These characteristics allow diesel to self-ignite under high temperature and pressure, whereas gasoline requires spark ignition. Therefore, diesel engines usually do not have spark plugs and rely on the high temperature and pressure during compression for self-ignition.

3. Combustion Process

The combustion process of diesel generators follows the constant-pressure Diesel cycle, while gasoline generators follow the constant-volume Otto cycle. In diesel generators, atomized diesel enters the cylinder and mixes with air. When the temperature reaches the auto-ignition point, combustion begins. Because diesel burns slowly, fuel injection continues during combustion, allowing ongoing mixing and ignition, and the expanding gases continuously push the piston. In gasoline generators, the air-fuel mixture for the power stroke is fully prepared before ignition. The spark plug ignites the mixture near the top dead center, and combustion occurs almost instantaneously in a nearly constant-volume space, rapidly expanding and performing work.

4. Application Scenarios

Due to their high efficiency, economy, stability, and low emissions, diesel generator sets are commonly used in scenarios requiring high reliability and high efficiency, such as large vehicles, heavy-duty construction vehicles, ships, and power stations. Gasoline generator sets are more often used in small equipment or light-load scenarios, such as household backup power or small construction sites.

Conclusion

Diesel generator sets, with their high efficiency, economy, stability, and environmentally friendly characteristics, are the first choice for many users in scenarios requiring high reliability and high-efficiency power generation. The compression ignition method, as the core technology of diesel generator sets, achieves efficient combustion by causing the fuel to self-ignite under high temperature and high pressure. Users must master proper maintenance and care to ensure long-term stable operation. With continuous technological advancement, the performance and environmental protection of diesel generator sets will further improve, providing more reliable power support.

In summary, diesel generator sets are highly practical power generation devices suitable for various complex operating conditions. Their compression ignition method not only improves power generation efficiency but also reduces operating costs and environmental impact. This article aims to help you better understand diesel generator sets and their compression ignition method, offering an ideal solution for your power needs.

Send your message to this supplier

Related Articles from the Supplier

Compression Ignition Method of Diesel Generator Sets

- Nov 17, 2025

Maintenance of Diesel Generator Sets in Summer

- Nov 12, 2025

Introducing the Fuel System of Diesel Generator Sets

- Mar 24, 2025

Guide to Long-Term Storage of Diesel Generator Sets

- Mar 26, 2025

Cost Analysis of Your Diesel Generator Sets

- Nov 10, 2025

Related Articles from China Manufacturers

Connection method of seamless tube

- Sep 19, 2023

Processing Method of Weld Neck Flanges

- May 20, 2021

Testing method of plastic coated steel pipe

- Nov 17, 2023

Galvanized Method of Seamless Steel Pipe

- Jul 25, 2023

Classification Method of Seamless Steel Pipe

- Jul 19, 2022

Material Selection Method of Knife Gate Valve

- Dec 14, 2024

The Forming Method of Square Steel Tube

- Jul 20, 2020

Related Products Mentioned in the Article

- www.chinatopper.com

- Address: Xiamen

- Phone: 86-592-5819200

- Business Type: Trading, Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.chinageneratorsets.com/news/compression-ignition-method-of-diesel-generator-sets.html