- Products

- Industrial Parts

- Metallurgy, Chemicals, Rubber & Plastics

- Hardware

- Bags, Shoes & Accessories

- Packaging, Advertising & Office

- Electronics

- Home, Lights & Construction

- Apparel,Textiles & Accessories

- Machinery

- Agriculture & Food

- Tools

- Electrical Equipment, Components & Telecoms

- Auto & Transportation

- Gifts, Sports & Toys

- Health & Beauty

- Measurement & Analysis Instruments

- Suppliers

- News

- For Sale

LQRY Thermal Oil Pump (Heat Conductive Hot Oil Pump)

Key Specifications / Features

China LQRY Thermal Oil Pump Manufacturer Shinjo Supplies Good QuiltyHeat conductive hot oil pump.

Request a quote

Detail Information

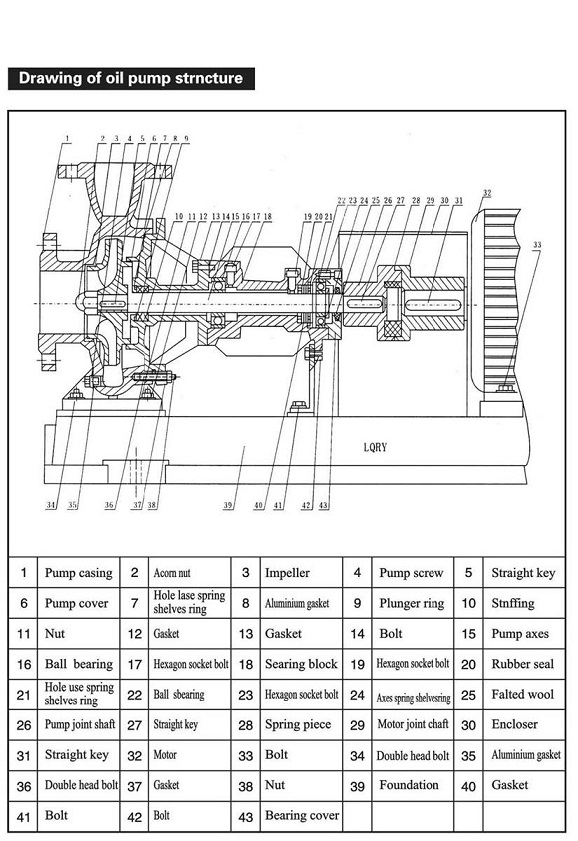

LQRY Thermal Oil Pump (Heat Conductive Hot Oil Pump) developed by absorbing many counterparts advantages, which enables the product many characteristics, for instance, reasonable construction, high efficiency, zero leakage in long term function etc, widely applied in the field of Petrol, oil, boiler, buildings, road, pharmacy, plastics, combined fiber, printing and dyeing sectors etc. Is a good hot medium pump, working temp is ≤ 350C

Structure characteristics:

LQRY thermal oil pump is our new designer by absorbing advantages of other country's products, the main structure is single-stage, and single-suction cantilevered structural support. The intake is axial direction suction, as well the output is center upright, which install into seat with motor.

LQRY thermal oil pump adopt double-pointed ball bearing structure, the front side use lubricating oil, the backside use grease lubricant, between them, is oil conductive pipe, to observe the seal condition and recycle heat-conductive oil.

It adopt self heat emanate system, change tradition water cooling system, the structure is simple, small size and economize the power.

LQRY use stuffing seal and mechanism seal combine style, stuffing seal is made of high temperature bearable stuffing, which has good ability of anti-high temperature; Whereas the mechanism seal use hard metal of wearable high mechanical strength, assure the seal capability in condition of high temperature.

LQRY use third-generation poly fluortetraethylene (PTFE) to make lip seal, so the seal performance is super good, 25 times sealability than rubber seal and it anti-corrosive.

Structure characteristics:

LQRY thermal oil pump is our new designer by absorbing advantages of other country's products, the main structure is single-stage, and single-suction cantilevered structural support. The intake is axial direction suction, as well the output is center upright, which install into seat with motor.

LQRY thermal oil pump adopt double-pointed ball bearing structure, the front side use lubricating oil, the backside use grease lubricant, between them, is oil conductive pipe, to observe the seal condition and recycle heat-conductive oil.

It adopt self heat emanate system, change tradition water cooling system, the structure is simple, small size and economize the power.

LQRY use stuffing seal and mechanism seal combine style, stuffing seal is made of high temperature bearable stuffing, which has good ability of anti-high temperature; Whereas the mechanism seal use hard metal of wearable high mechanical strength, assure the seal capability in condition of high temperature.

LQRY use third-generation poly fluortetraethylene (PTFE) to make lip seal, so the seal performance is super good, 25 times sealability than rubber seal and it anti-corrosive.

| Working Principle: | Centrifugal |

| Main applications: | Hot oil, thermal oil, high temperature oil, etc |

| Driver: | Electric motor, diesel motor. |

| Power Specs: | 220/380/400/415V 3phase;50hz/60hz |

| Max.permissible fluid temperature: | 350°C |

| Type of connection: | Flange |

| Installation position: | Horizontal |

| Casing parts material: | Cast steel |

| Shaft seal type: | Shaft seal ring, Mechanical seal, Carbon seal |

| Free passage: | 1mm |

| Maximum viscosity: | 5X104C.S.T |

| Maximum drive rating: | 132KW (180HP) |

| Maximum caliber: | 150mm (6inch) |

| Maximum discharge-side pressure: | 0.85Mpa (8.5bar) |

| Maximum head: | 85m (278.8ft) |

| Flow rate range: |

4.5-400m³/h(19.8-1760US.GPM) |

| Model | Capacity (m3/h) |

Head (m) |

Speed (r/min) |

Shaft Power (kw) |

Motor Power (kw) |

| 26-20-100 | 4.5 | 15 | 2825 | 0.45 | 0.75 |

| 50-32-150 | 8 | 22 | 2900 | 1 | 1.5 |

| 50-32-160 | 10 | 25 | 2900 | 1.5 | 2.2 |

| 65-40-160 | 12.5 | 25 | 2900 | 2.5 | 3 |

| 50-50-170 | 12.5 | 32 | 2900 | 3.2 | 4 |

| 65-50-180 | 32 | 32 | 2900 | 4.5 | 5.5 |

| 65-50-170 | 40 | 25 | 2900 | 4.5 | 5.5 |

| 80-50-180 | 40 | 40 | 2900 | 6.7 | 7.5 |

| 80-50-170 | 60 | 20 | 2900 | 6.7 | 7.5 |

| 100-65-190 | 60 | 38 | 2930 | 9.2 | 11 |

| 100-65-200 | 80 | 40 | 2930 | 12.5 | 15 |

| 100-65-220 | 58 | 50 | 2930 | 12.5 | 15 |

| 100-65-230 | 100 | 55 | 2940 | 19.5 | 22 |

| 125-100-190 | 155 | 30 | 2940 | 20 | 22 |

| 100-65-240 | 100 | 70 | 2950 | 25.5 | 30 |

| 100-65-257 | 100 | 80 | 2950 | 32.5 | 37 |

| 125-100-220 | 160 | 45 | 2950 | 25.5 | 37 |

| 125-80-250 | 160 | 60 | 2970 | 35.5 | 45 |

| 125-100-257 | 200 | 60 | 2970 | 42.8 | 55 |

| 125-100-260 | 260 | 70 | 2970 | 64.3 | 75 |

| 125-100-270 | 300 | 70 | 2970 | 75.3 | 90 |

| 125-100-270 | 220 | 85 | 2970 | 68 | 90 |

| 150-125270 | 340 | 76 | 2970 | 89.5 | 110 |

| 150-125-270 | 400 | 78 | 2970 | 106 | 132 |

Send your message to this supplier

FAQs

Similar Products

Related Searches

Products you might also like

Categories

Supplier Website

Source: https://www.shinjopump.com/lqry-thermal-oil-pump-heat-conductive-hot-oil-pump.html

Copyright © 2015-2026 China Manufacturers, CNMFRS.COM, All rights reserved.

谷歌优化(Google SEO)