Gate Valves and Globe Valves: A Comprehensive Comparison

In industrial piping systems, valves play a crucial role in precisely controlling the flow of fluids. Gate valves and globe valves, as two common types of valves, are often mentioned for their ability to cut off the medium. However, there are significant differences between these valves in terms of structure, performance, application scenarios, and many other aspects. This article will delve into the differences between gate valves and globe valves to help you make wiser choices in practical applications.

Structural Differences Between Gate Valves and Globe Valves

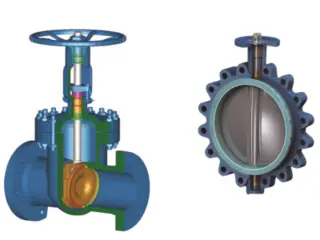

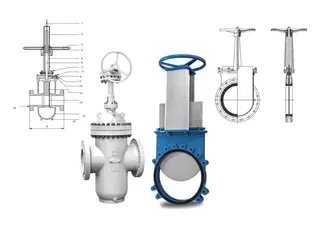

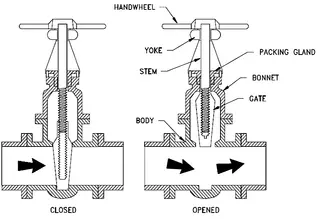

The structure of a gate valve is relatively complex. It is usually composed of main components such as the valve body, gate, valve stem, and valve seat. The gate of a gate valve can be either parallel or wedge-shaped, and the wedge-shaped gate is further divided into single-gate and double-gate types. There are two forms of valve stems in gate valves: rising stem and non-rising stem. In a rising stem gate valve, the valve stem nut is located outside the valve body, and the movement of the valve stem is clearly visible, which facilitates operation and monitoring. In a non-rising stem gate valve, the valve stem nut is inside the valve body, and the valve stem only rotates without moving up or down, giving it a more streamlined appearance. However, the degree of valve opening must be judged by other means during operation. This structure of the gate valve makes it relatively large in height and size, especially the rising stem gate valve, which requires a higher vertical space to accommodate the movement of the valve stem.

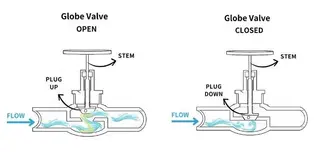

The structure of a globe valve is relatively simple, mainly consisting of components such as the valve body, disc, valve stem, and valve seat. The sealing surface of the disc and valve seat of a globe valve is perpendicular to the direction of fluid flow. The disc moves up and down under the action of the valve stem to open and close the valve. The valve body of a globe valve is usually in the shape of an "S" or "Z," which makes it perform poorly in terms of fluid resistance but provides better regulating performance.

Performance Comparison of Gate Valves and Globe Valves

Valve performance is defined by factors such as fluid resistance, sealing, operating force, and regulating capability. These characteristics directly influence service life and application suitability, making it essential to understand the differences between gate and globe valves.

1. Fluid Resistance

When fully open, gate valves provide a nearly straight flow path, resulting in very low resistance (coefficient 0.08–0.12). This makes them well-suited for high-flow, low-pressure-drop systems such as steam networks and large-diameter pipelines, where energy efficiency and smooth flow are priorities.

Globe valves, by contrast, force fluid to change direction, giving them a much higher resistance (3.5–4.5). This limits their use in high-flow applications but offers an advantage in scenarios requiring precise flow regulation.

2. Sealing Performance

Gate valves rely on medium pressure to press the gate against the seat, but because the two surfaces remain in contact throughout operation, wear is common, especially under high pressure differentials. Imperfections, erosion, or poor surface fit can lead to leakage over time.

Globe valves generally provide better sealing. Contact between the disc and seat occurs only at closure, reducing wear and improving tightness under equal conditions. However, solid particles in the medium can damage the sealing surfaces, and insufficient closure may allow erosion during high-speed flow.

3. Operating Force and Performance

Gate valves require relatively little operating force or torque, as movement is mainly vertical lifting with minimal friction. They are best for applications with long periods of full open or closed service, though they require more installation space and are less practical where frequent operation is needed.

Globe valves demand greater force, typically 2.5 to 3.5 times that of gate valves, because of higher flow resistance and surface friction. Still, their operation is smoother, travel is shorter, and they open and close more quickly, making them effective where faster response is needed.

4. Regulating and Throttling

Gate valves are poorly suited for throttling. Partial opening causes high-speed flow through narrow passages, leading to vibration, erosion, and potential leakage, while offering little accuracy in regulation.

Globe valves, however, are designed for regulation. The adjustable disc-seat opening allows precise flow control, making them indispensable in industries such as chemical and pharmaceutical production where accuracy is critical.

Application Scenarios of Gate Valves and Globe Valves

Gate valves and globe valves, with their unique performance characteristics, play irreplaceable roles in different industrial fields and specific conditions.

1. Application Scenarios of Gate Valves

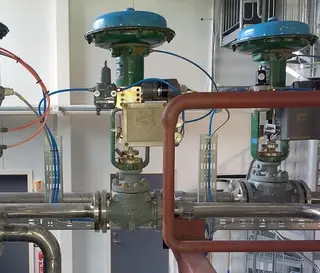

Gate valves are usually suitable for conditions that do not require frequent opening and closing and require low fluid resistance. In steam systems, the low resistance characteristic of gate valves can ensure smooth steam flow and reduce energy loss. In large-diameter pipelines, gate valves can meet the demand for high-flow transportation. At the same time, their short structural length and relatively small installation space make them suitable for use in situations with limited space. For example, in oil and natural gas transmission pipelines, gate valves are widely used to cut off the fluid and ensure the safe operation of the pipelines. In addition, gate valves can also be used in water treatment systems, power systems, and other places where fluid needs to be cut off.

2. Application Scenarios of Globe Valves

Globe valves are usually used in small-diameter pipelines and situations that require good sealing performance. In small-diameter pipelines, the simple structure and small size of globe valves make them easy to install and maintain. The good sealing performance of globe valves can effectively prevent fluid leakage and is suitable for conditions with high sealing requirements. For example, in the pipeline systems of the chemical and pharmaceutical industries, globe valves are often used to cut off and regulate corrosive and toxic media. In addition, globe valves are also suitable for situations that require precise regulation of fluid flow, such as laboratories and metering systems. In these situations, the regulating performance of globe valves can meet the demand for precise control of fluid flow.

How to Choose the Right Valve?

When selecting a gate valve or a globe valve, it is necessary to take into account a variety of factors, including the requirements of the working conditions, the characteristics of the fluid, the installation space, and the maintenance cost.

1. Selection Based on Working Conditions

If the working conditions require low fluid resistance, low opening and closing force, and infrequent opening and closing, a gate valve is suitable. For example, in steam systems and large-diameter pipelines, gate valves can meet the demand for high-flow transportation while reducing system pressure loss. If the working conditions require good sealing performance and good regulating performance, a globe valve is suitable. For example, in small-diameter pipelines and situations that require precise control of fluid flow, the sealing and regulating performance of globe valves can meet the requirements of the working conditions.

2. Selection Based on Fluid Characteristics

If the fluid contains solid particles, has a high viscosity, or is prone to coking, a globe valve is not suitable because these impurities may damage the sealing surface of the globe valve. In this case, a gate valve may be a better choice. If the fluid has high sealing requirements and needs precise flow regulation, a globe valve is more appropriate.

3. Selection Based on Installation Space

If the installation space is limited, it is necessary to consider the height and size of the valve. Gate valves are relatively tall, especially rising stem gate valves, which require a higher installation space. Globe valves have a relatively compact structure and smaller size, making them suitable for installation in situations with limited space.

4. Selection Based on Maintenance Cost

If the maintenance cost of the valve is an important consideration, a globe valve may be a better choice. The simple structure of globe valves makes maintenance easier, and most of their valve seats and discs can be replaced online, reducing maintenance time and cost. The maintenance of gate valves is relatively difficult, requiring the entire valve to be removed from the pipeline for repair, which increases maintenance cost and time.

Conclusion

Although both gate valves and globe valves have the function of cutting off the medium, there are significant differences between them in terms of structure, performance, application scenarios, and other aspects. Gate valves have a complex structure, low fluid resistance, and low opening and closing force, but their sealing surface is prone to wear, and maintenance is difficult. Globe valves have a simple structure, good sealing performance, and good regulating performance, but they have higher fluid resistance and opening and closing force. When selecting a valve, it is necessary to comprehensively consider factors such as the requirements of the working conditions, the characteristics of the fluid, the installation space, and the maintenance cost to choose the most suitable type of valve.

Send your message to this supplier

Related Articles from the Supplier

A Comprehensive Guide to Bellows Sealed Globe Valves

- Jun 19, 2025

Electric V-Type Ball Valves: A Comprehensive Guide

- Jul 16, 2025

Wedge Gate Valves: Structure, Types and Maintenance

- May 22, 2025

A Maintenance Guide to Faulty Control Valves

- Jul 14, 2025

Related Articles from China Manufacturers

The Differences Between Ball Valves and Globe Valves

- May 10, 2019

A Comparison of Gate Valves and Other Valves

- Dec 14, 2020

A Combination of Gate Valves and Check Valves

- Jun 07, 2023

Related Products Mentioned in the Article

- www.chinatopper.com

- Address: Xiamen

- Phone: 86-592-5819200

- Business Type: Trading, Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.valvepackingsealkits.com/news/gate-valves-and-globe-valves-a-comprehensive-comparison.html