Pipe Cap Hot-Forming: Heating Temperature and Blank Size Study

Abstract: A numerical simulation study of pipe cap hot forming was conducted using DEFORM-3D finite element analysis software to determine the optimal heating temperature and dimensions of the pipe cap blank. The results offer valuable guidance for the design and manufacturing of pipe caps. Pipe caps are widely used in petroleum, chemical, and power plant pipelines, and their quality directly impacts the integrity and safety of the entire pipeline system. With the increasing adoption of high-pressure, large-diameter, and long-distance pipelines, the mechanical performance requirements for pipe caps and other fittings are becoming ever more stringent. This study uses DEFORM-3D finite element analysis to simulate the heating temperature and dimensions of pipe cap blanks during hot forming. The results identify the optimal parameters for hot forming pipe cap blanks, providing a solid foundation for addressing challenges in thermoforming process design and practical production.

1. Establishing a Numerical Simulation Model for Pipe Cap Thermoforming

1.1 Simulation Object

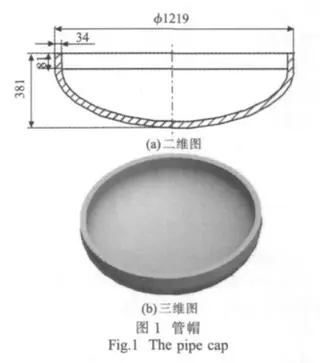

The simulation object is a pipe cap with dimensions of 1219 mm × 34 mm, as shown in Figure 1. The key parameters are: outer end diameter 1219 mm, wall thickness 34 mm, total length 381 mm, and shoulder length 81 mm.

1.2 Mold and Blank Model

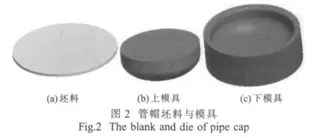

The mold and blank were designed using the 3D modeling software Pro/E. Solid 3D models were created and then converted into the STL format required by the DEFORM-3D numerical simulation software. The three-dimensional structures of the 1219 mm × 34 mm pipe cap blank, upper die, and lower die are shown in Figure 2.

Figure 1. Pipe cap

(a) Two-dimensional view (b) Three-dimensional view

Figure 2. Pipe cap blank and dies

(a) Blank (b) Upper die (c) Lower die

1.3 Performance Parameters

The deformation resistance of a material within a given temperature range is a critical factor in determining the forming process and selecting the appropriate forming equipment. Since deformation resistance strongly affects simulation accuracy, precise data collection is essential. A dynamic material thermal simulation testing machine was used, with its computer system automatically recording true stress, strain, pressure, displacement, temperature, and time. These data were used to establish the simulation material model. Based on them, the material stress–strain curve was plotted, as shown in Figure 1. The pipe blank material used in this simulation was X80 steel. The key calculation parameters for the numerical simulation of pipe cap hot press forming are listed in Table 1.

Table 1. Basic Parameters for Numerical Simulation

|

Parameter |

Value |

|

Workpiece thermal conductivity (W·m⁻¹·K⁻¹) |

35.5 |

|

Workpiece specific heat capacity (J·kg⁻¹·K⁻¹) |

6.1073 |

|

Heat transfer coefficient between die and workpiece (N·s⁻¹·mm⁻²·K⁻¹) |

0.5 |

|

Die temperature (°C) |

20 |

|

Friction coefficient |

0.3 |

|

Main die velocity (mm·s⁻¹) |

10 |

|

Ambient temperature (°C) |

20 |

|

Upper die velocity (mm·s⁻¹) |

10 |

2. Determining the Blank Heating Temperature

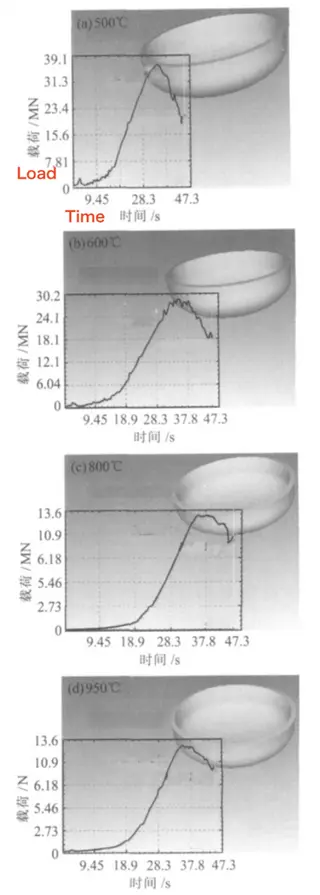

In the hot forming process, selecting the appropriate blank heating temperature is critical. If the temperature is too low, the blank exhibits high deformation resistance, which can reduce die life. Conversely, if the temperature is too high, the surface quality of the formed workpiece deteriorates, and the die temperature rises during forming, further shortening die life. Before hot forming, the metal blank must be heated to an appropriate temperature. As the heating temperature increases, the blank’s ultimate strength decreases, while its plasticity improves. The forming temperature should be as high as possible without causing overheating. However, in actual production, the heating temperature is influenced by practical conditions. Excessively high temperatures not only fail to sufficiently reduce deformation resistance but also result in unnecessary energy consumption. The blank heating temperature directly determines whether the metal can be successfully formed into the desired shape after deformation, and therefore has a decisive impact on both experimental and production outcomes. To investigate its effect, simulations were conducted at billet heating temperatures of 500 °C, 600 °C, 800 °C, and 950 °C. The results are shown in Figure 3. Analysis revealed that the heating temperature had little effect on overall formability, as acceptable workpiece appearances were achieved at all tested temperatures. Excessively low temperatures, however, significantly increase deformation resistance, thereby raising the required forming force. At 500 °C, the forming force was nearly three times higher than at 950 °C. Excessive forming forces accelerate die wear and require high-tonnage presses, thereby increasing production costs.

Figure 3. Forming force at different heating temperatures

Based on practical experience, heating temperatures above 1000 °C place excessive demands on the heating equipment and can easily cause oxidation on the die surface. In conclusion, for optimal efficiency, a billet heating temperature of 950 °C was selected, provided that the forming load requirements are met.

3. Determining Blank Size

3.1 Theoretical Calculation of Blank Size

The method for calculating the blank area for cap forming is based on JB4767-2002, which specifies the surface area calculation for elliptical heads (EHAs).

3.2 Determining the Final Blank Size

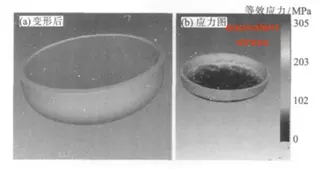

Based on preliminary analysis, cap blanks with diameters of 1500 mm and 1600 mm, both having a thickness of 34 mm, were selected for evaluation. Simulations of the cap forming process were conducted for each blank, and the results are shown in Figures 4 and 5.

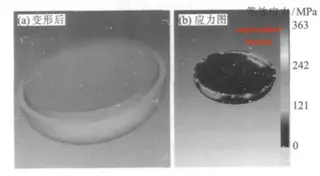

(a) After deformation (b) Stress distribution

Figure 4. Forming simulation of a blank with a diameter of 1500 mm

The simulation results show that different blank sizes produce different forming outcomes. For the blank with a diameter of 1500 mm, the shoulder of the pipe cap lacks sufficient machining allowance after forming. In contrast, the blank with a diameter of 1600 mm provides adequate machining allowance at the shoulder. Therefore, the blank with a diameter of 1600 mm yields more favorable dimensions than the 1500 mm blank. Ultimately, a blank with a diameter of 1600 mm and a thickness of 34 mm was selected for forming the 1219 mm × 34 mm pipe cap.

Figure 5. Forming simulation of a blank with a diameter of 1600 mm

4. Conclusion

The hot pressing process of a 1219 mm × 34 mm pipe cap was simulated using DEFORM-3D software. The optimal blank parameters were determined as follows: a heating temperature of 950 °C, a diameter of 1600 mm, and a wall thickness of 34 mm.

Send your message to this supplier

Related Articles from the Supplier

Advantages and Features of Stainless Pipe Cap

- Aug 05, 2015

Pipe Fittings for Oil and Gas Pipelines

- Dec 27, 2024

Challenges in the Manufacturing of Pipe Fittings

- Jan 02, 2025

Improving the Quality of Pipe Fittings

- Jan 24, 2025

Related Articles from China Manufacturers

Advantages and Features of Stainless Pipe Cap

- Nov 29, 2016

Prospects of Pipe Fittings Industry

- Sep 22, 2015

How to Pick out Pipe Fittings with High Quality

- Sep 16, 2013

Pipe Line Can be Protected by New Sanitary Valves

- Apr 28, 2014

Pipe Line Can be Protected by New Sanitary Valves

- Sep 23, 2016

Related Products Mentioned in the Article

Supplier Website

Source: https://www.landeepipefitting.com/pipe-cap-hot-forming-heating-temperature-and-blank-size-study.html