Pipeline Welding: Key Standards, Challenging Sections, and Future Trends

2. Pipeline Welding Standards

Pipeline welding standards are essential for advancing modern welding technologies and ensuring standardized, safe, and reliable pipeline construction. Today, welding standards have evolved into a comprehensive system with detailed requirements for welding procedures, techniques, and materials. For example, GB/T 31032-2014 Welding and Acceptance of Steel Pipelines specifies butt welding requirements for carbon steel and low-alloy steel pipes and fittings used in transporting crude oil, refined oil, natural gas, carbon dioxide, nitrogen, and other media. It also includes specifications for gas welding and arc welding of corner joints and socket joints used in pipelines, valve stations, and compressor rooms.

GB/T 25776-2010 Welding Process Performance Evaluation Methods for Welding Materials outlines standardized testing methods for arc stability, slag removal, re-ignition performance, spatter rate, melting rate, deposition efficiency, and welding fume emissions to ensure consistent performance of welding consumables.

GB 9448-1999 Welding and Cutting Safety is an updated revision of GB 9448-1988, aligning with the U.S. ANSI/AWS Z49.1 standard, and provides comprehensive safety guidelines for welding and cutting operations to minimize workplace hazards.

GB/T 34275-2017, Pressure Pipeline Specification for Long-Distance Pipelines, covers design, materials, installation, non-destructive testing (NDT), commissioning, operation, maintenance, and inspection requirements for in-service pipelines.

GB 50236-2011, Construction Specification for Field Equipment and Industrial Pipeline Welding Projects, was established to enhance onsite welding quality, strengthen process control, and ensure safe, reliable welding in equipment and industrial metal pipeline construction.

SY/T 4125-2013, Steel Pipeline Welding Code, applies to welding and installation of long-distance pipelines and oil and gas field gathering systems, covering the transportation of gas, liquids, and slurry media.

These national standards play a vital role in ensuring welding quality and safety across critical industries like oil and gas, petrochemicals, and energy infrastructure. Their implementation is essential for regulatory compliance, enhancing project efficiency, and ensuring the long-term reliability of pipeline systems.

International Standards for Pipeline Welding: ASME, API, EN, DIN, and ISO

Besides domestic GB standards, various international standards specify detailed requirements for pipeline classification, weld design, inspection methods, and overall welding quality and safety assurance. Globally, numerous professional standardization organizations have established comprehensive frameworks to regulate and guide pipeline welding in critical high-risk industries including oil and gas, petrochemicals, nuclear power, and industrial processing.

ASME Standards (USA)

ASME B31.1 specifies design and construction requirements for process piping systems used in petrochemical, electric power, nuclear energy, and other industrial sectors, ensuring safety and reliability in critical applications. It mandates that pipeline materials comply with strict chemical composition, mechanical property, and impact toughness requirements, while welds must follow approved welding procedure specifications (WPS) and pass rigorous non-destructive testing (NDT).

ASME B31.4 and ASME B31.8 establish standards for the design and construction of liquid and gas transmission pipeline systems, respectively, encompassing material selection, weld quality control, inspection procedures, and comprehensive safety assurance.

API Standards (American Petroleum Institute)

API 5L defines technical specifications for steel pipes used in oil and natural gas transportation, covering essential aspects such as material properties, chemical composition, and mechanical strength to ensure pipeline safety and performance.

API 1104 sets welding quality standards and procedures to evaluate weld performance, ensuring the integrity and reliability of welded joints in pipeline systems.

API 570 addresses the inspection, evaluation, and re-certification of in-service pipeline systems, establishing standards for risk-based inspection, assessment methods, and continuous pipeline safety monitoring to ensure operational reliability.

European Standards (EN & DIN)

EN 10216-2 specifies requirements for seamless steel pipes made from non-alloy and alloy steels, covering dimensional tolerances, mechanical properties, and chemical composition to ensure quality and performance.

EN 13480 outlines comprehensive design and calculation standards for industrial pipeline systems, including pipeline classification, design pressure, welded joints, and support structures to ensure safety and reliability.

DIN 1626 specifies standards for seamless and welded long-distance pipelines, covering material requirements, mechanical properties, and dimensional accuracy to ensure pipeline integrity and performance.

DIN EN 287-1 establishes qualification standards for welders, including welding procedure tests, to ensure weld integrity and process reliability.

ISO Standards (International Organization for Standardization)

ISO 3183 defines material and technical specifications for steel pipelines in oil and gas transport, ensuring consistent mechanical strength, chemical composition, and corrosion resistance for safe and reliable operation.

ISO 9606-1 specifies welder qualification testing to ensure welders have the skills required to meet stringent international welding quality standards.

ISO 1106 outlines the preparation and evaluation methods for weld samples, including visual inspections, destructive and non-destructive testing, to ensure comprehensive weld quality assessment.

Conclusion: These internationally recognized pipeline welding standards—such as ASME, API, EN, DIN, and ISO—are essential for ensuring welding quality, process safety, and long-term pipeline durability in global engineering projects. Strict adherence to these standards is crucial for ensuring compliance, reducing risks, and maximizing the long-term performance and safety of pipeline systems in challenging environments.

3. Welding Solutions for Challenging Pipeline Sections in Oil and Gas Projects

Welding solutions for complex pipeline sections in oil and gas transmission projects are typically categorized into several scenarios, including mountainous (climbing) terrain construction, welding of large or variable wall thickness pipelines, welding at corners and bends, welding across paddy fields, fish ponds, and river crossings, as well as large-diameter pipeline welding.

3.1 Climbing Construction in Mountainous Terrain

Climbing construction is frequently used in pipeline welding projects situated in mountainous terrain, where steep slopes, deep valleys, and uneven ground create complex working conditions. Successful welding in these areas requires thorough planning and consideration of environmental, logistical, and safety factors.

Welding Methods: A combination of semi-automatic and manual welding is commonly employed in mountainous pipeline construction to adapt to uneven terrain and complex environmental conditions.

Construction Equipment: Pipe hoists and specialized lifting equipment are frequently deployed in mountainous pipeline projects to handle elevation changes and ensure safe, accurate pipe alignment and positioning.

Key challenges in mountain pipeline welding include:

Complex topography – Steep slopes, cliffs, and unstable ground conditions significantly hinder pipeline transportation, precise alignment, and lifting operations during construction.

Harsh environmental conditions – Frequent high winds, heavy rainfall, and extreme temperature fluctuations pose serious safety hazards and significantly reduce welding efficiency and overall construction productivity.

Recommended solutions:

Strengthen deployment of construction equipment – Utilize specialized hoisting and lifting machinery designed for steep or elevated terrain to enhance operational efficiency and ensure safety in mountainous pipeline welding projects.

Enhance safety management – Enforce strict operating protocols, conduct real-time weather surveillance, and perform comprehensive geological risk assessments to reduce the likelihood of landslides, soil erosion, and other terrain-related hazards.

3.2 Welding for Large and Variable Wall Thickness Pipelines

Welding pipelines with large or variable wall thicknesses must comply with relevant national and international standards, including but not limited to:

GB 50251-2015 – Design Code for Gas Transmission Pipeline Engineering

ASME B31.8-2007 – Gas Transmission and Distribution Piping Systems

Welding techniques vary according to pipe joint types, such as spiral welds or longitudinal welds. Common methods include double-sided submerged arc welding (SAW) and high-frequency welding, which is suitable for pipes with specific diameter and wall thickness.

Primary Challenges Include:

Severe welding deformation: High thermal input often leads to residual stresses and geometric distortions.

Limited adaptability of automated welding equipment: Standard automated systems may struggle to accommodate the dimensional variability of large or variable wall thickness pipelines.

Effective Countermeasures:

Preheating before welding: Minimizes residual stress and reduces the risk of cracking caused by rapid temperature changes.

Develop specialized automated welding systems: Design and deploy equipment tailored for large-diameter, variable-thickness pipes to improve weld quality and consistency.

Conclusion: Welding in challenging pipeline sections—such as mountainous terrain and large-diameter segments—demands adaptive welding technologies, specialized equipment, and strict compliance with industry standards to ensure safety, quality, and durability. By implementing tailored welding solutions and stringent safety protocols, oil and gas pipeline construction teams can ensure structural integrity, weld reliability, and project success—even in the most challenging environments.

Corner and Elbow Pipe Welding Solutions

Welding corner and pipe elbow is inherently more complex due to their geometric structure and demanding environmental conditions. Elbow sections require enhanced strength and toughness to withstand stress concentrations and prevent welding cracks, as high toughness is essential for absorbing impact and resisting crack formation during and after welding. Before welding large-diameter pipe elbow, it is essential to evaluate the welding procedure, thoroughly clean and decontaminate the pipe ends, and preheat both the base materials and welding consumables. These steps effectively minimize residual stress and significantly reduce the risk of weld cracking.

For large-diameter elbows, the recommended welding sequence typically includes manual arc welding (SMAW) for root passes, followed by submerged arc welding (SAW) for fill and cap passes.

Post-weld heat treatment (PWHT) is essential for relieving residual stress, detecting potential cracks, and ensuring that weld mechanical properties meet strict quality standards.

Main Challenges in Elbow Pipe Welding

Complex stress distribution: The curved geometry of elbow pipes causes uneven internal stresses, making deformation and residual stress control difficult.

Large weld gaps: Elbow joints often face fit-up challenges, resulting in weld gaps that are harder to fill consistently and securely.

Effective Solutions Include:

Optimizing elbow design using multi-segment reducer transitions to improve stress distribution and minimize weld gap challenges.

Applying localized preheating and post-weld heat treatment to relieve residual stress and enhance structural stability.

Welding Solutions for River, Paddy Field, and Fish Pond Crossings

Welding in river crossings, paddy fields, and fish pond areas requires strict safety protocols due to challenging environments, unstable terrain, and heightened geological risk. Comprehensive geological surveys must be conducted before construction to confirm the site is free from active faults, unstable soil, or other ground hazards. Tailored welding strategies should be developed based on the specific conditions of each crossing site to ensure structural integrity and meet environmental requirements. Crossing construction generally follows a trapezoidal vertical sequence, beginning with water diversion and trench excavation, followed by sectional pipe welding and final system integration.

Key challenges in river crossing pipeline welding include:

Stringent geological stability requirements – Crossing zones are often susceptible to landslides, soil erosion, or subsidence, posing significant risks of geological hazards.

Harsh environmental conditions – High humidity, water intrusion, and unstable terrain complicate construction and hinder consistent weld quality.

To address these challenges, the following measures are recommended:

Conduct comprehensive geological surveys to evaluate and mitigate risks such as landslides, flooding, and soil displacement.

Implement robust environmental controls during welding operations by using moisture-proof covers, localized heating, and dehumidification systems to maintain weld integrity and ensure operational safety.

Large-diameter pipeline welding typically utilizes automated or semi-automated techniques to improve welding accuracy, efficiency, and consistency. As a result, the performance and precision of automated welding equipment are critical to achieving high weld quality and ensuring the long-term reliability of pipeline systems. One of the key challenges in automated welding of large-diameter pipelines is managing significant weld deformation and maintaining equipment stability under high operational demands. To overcome these challenges and ensure high-quality welds, the following measures are essential:

Establish precise welding mathematical models and optimize control strategies to ensure consistent arc behavior and penetration depth. Customize welding equipment designs to enhance adaptability across diverse terrains and operating conditions.

As illustrated in Figure 5, challenging terrains—such as mountainous regions, steep slopes, and river crossings—demand specialized welding plans customized for each unique environment. The general pipeline welding process includes team formation and personnel assignment, pre-weld surface preparation and preheating, followed by welding stages such as root pass, fill pass, and cap pass.

Post-weld heat treatment

Non-destructive testing (NDT) to detect welding defects

Post-weld heat treatment and non-destructive testing (NDT) are essential to detect welding defects. For difficult pipeline sections, welding schemes must account for factors like terrain, temperature, wind speed, and humidity. Key construction considerations include:

Root pass welding is typically performed using SIT welding, while filler passes use semi-automatic downhill welding. Acceptable environmental conditions include wind speeds up to 5 m/s for arc welding and 8 m/s for semi-automatic welding, humidity below 90%, and ambient temperatures above 5°C.

In mountainous or complex terrain, additional measures such as internal plugging should be used to stabilize internal airflow and minimize porosity in welds. Increase prefabrication volume to minimize elevation differences and simplify onsite assembly. Optimize process scheduling according to terrain layout and environmental factors to improve efficiency. Construction of complex pipeline sections demands site-specific analysis and tailored process adjustments to ensure successful execution. Selecting appropriate welding methods based on site conditions is critical to ensuring pipeline safety, performance, and durability in challenging sections.

Figure 5: Construction Sites of Various Difficult Pipeline Sections

Pipeline Construction Process and Site Work Procedures

Measurement and Layout Marking for Accurate Pipeline Positioning

Weld Repair and Defect Patching to Ensure Pipeline Integrity

Anti-Corrosion Coating Inspection and Leak Detection for Long-Term Protection

Construction Access Road and Work Zone Clearing to Facilitate Safe Operations

Non-Destructive Testing (NDT) Including Ultrasonic and Radiographic Inspection

Fine Soil Backfilling to Stabilize the Pipeline Trench

Trench Excavation and Preparation Following Project Specifications

Trench Re-survey and Soil Compaction for Structural Stability

Classification and Group Welding to Optimize Fabrication Efficiency

Pipeline Layout and Classification for Organized Installation

Selection and Allocation of Steel Pipes and Prefabricated Bends to Meet Design Requirements

Hydraulic Protection Measures and Environmental Restoration to Prevent Erosion and Preserve Landscape

4. Development Trends in Pipeline Welding Technology

With the rapid expansion of pipeline transportation, demands for higher efficiency, greater capacity, and longer-distance pipelines continue to rise steadily. Traditional pipeline welding methods can no longer meet today’s performance and safety standards, making it essential to adopt innovative welding technologies that better address current and future pipeline construction challenges. Pipelines are evolving toward larger diameters, thicker walls, higher pressures, and longer transmission distances, driving the need for targeted improvements in welding processes to ensure safety and efficiency.

For pipelines operating under extreme or demanding conditions, technological innovation is essential and includes measures such as:

- Optimize welding procedures to enhance structural integrity and ensure long-term reliability.

- Select welding materials tailored to specific application requirements for better performance.

- Fine-tune process parameters to improve weld quality, strength, and durability.

Additionally, for challenging environments such as high temperature, high pressure, or hazardous gas applications, developing specialized welding techniques is essential to ensure safety, optimal performance, and regulatory compliance. Integrating digital technologies represents one of the most promising advancements in pipeline welding. By implementing welding data management systems, key parameters—such as heat input, weld geometry, arc stability, and defect rates—can be recorded, analyzed, and optimized in real time, enabling a data-driven approach that supports:

Key benefits include engineering analysis and predictive maintenance, process optimization and quality control, as well as remote monitoring and fault diagnostics enabled by smart sensor technology. The application of automated welding technology greatly enhances welding consistency while minimizing human error. Intelligent welding robots and automated welding systems enable high-speed, continuous operations, reducing labor costs and boosting efficiency—ideal for large-scale and remote pipeline projects. Looking ahead, intelligent welding powered by AI, machine learning, and IoT integration will enable welding robots to make real-time decisions, adapt to environmental changes, and self-correct deviations for enhanced precision and efficiency. This advancement will further improve the accuracy, repeatability, and overall efficiency of pipeline welding operations. In conclusion, the future of pipeline welding technology is advancing toward greater intelligence, automation, digitization, and optimized processes to meet evolving industry demands. These advancements will drive a more efficient, precise, and sustainable pipeline construction industry, fully equipped to meet the growing and evolving demands of global energy infrastructure.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

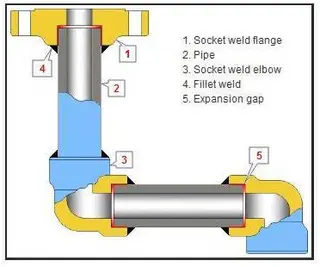

What Is The Socket Welding connection for pipeline

- Jun 16, 2019

What Is The Socket Welding connection for pipeline

- Jun 16, 2019

Related Products Mentioned in the Article

Supplier Website

Source: https://www.landeepipe.com/pipeline-welding-key-standards-challenging-sections-and-future-trends.html