Use and Difference of R and G Pipe Threads

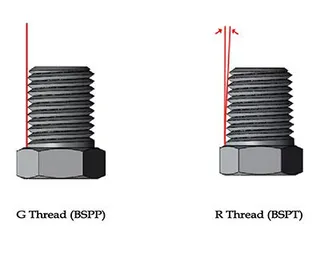

Pipe threads are essential components for connecting pipes and ensuring proper sealing and performance in fluid and gas systems. The types of pipe threads are classified based on their sealing capabilities and structural design. Two common types are the R (sealed) thread and the G (unsealed) thread.

R-Type Pipe Thread (Sealed)

The R type refers to sealed pipe threads and is available in four variations:

RP: Cylindrical internal thread paired with a conical external thread (R1).

RC: Conical internal thread paired with a conical external thread (R2).

The profile angle of both R and G threads is 55°. When written in specifications, subscripts (P, C, 1, and 2) are used to denote these different variations.

The R thread provides a tight seal once tightened, making it suitable for low-pressure applications such as water and gas pipes. The threads feature a 1:16 taper for the conical varieties and an arc-shaped tooth top and bottom.

G-Type Pipe Thread (Unsealed)

In contrast, G type pipe threads are unsealed cylindrical threads with a 55° profile angle. These threads are primarily used for connection purposes rather than sealing. G threads are often paired with sealing rings to handle low-pressure static loads in pipelines. The lack of sealing ability means that G threads do not offer a tight connection unless additional sealing measures are employed.

Thread Profiles and Code Standards

The R and G threads share the same 55° profile angle, but their sealing capabilities differ. In China’s older drawing standards, distinctions between sealed and unsealed threads were not explicitly made. The code for cylindrical pipe threads is g, while conical threads are denoted as ZG.

Comparison with NPT and NPTF Threads

NPT and NPTF (National Pipe Thread and National Pipe Tapered Fuel) threads are another commonly used type, particularly in the United States. These threads have a 60° profile angle and are also conical in shape. While NPT threads are used for sealing, NPTF threads are designed specifically for a "dry seal," ensuring a tight, leak-proof connection. NPT threads are often referred to as "American pipe threads," in contrast to the R and G threads, which are typically classified as "British pipe threads" in the international standards.

The NPT pipe thread was once known as the "taper pipe thread" or simply "Z" in China. It has a 1:16 taper like the R type, but the NPT thread is typically used for applications requiring a higher degree of sealing.

Differences Between G and R Pipe Threads

G-Type Pipe Threads (Unsealed): Used for low-pressure, non-sealing connections. Thread teeth are arc-shaped. No sealing performance by themselves; sealing is achieved with a gasket or sealing ring. Primarily used for static load applications in pipelines.

R-Type Pipe Threads (Sealed)

Designed for sealed connections with thread-tightening providing a leak-proof seal. Thread teeth are arc-shaped, and the threads have a 1:16 taper.

Two types of fit are available:

Cylindrical internal thread / Conical external thread: Suitable for low-pressure, static load applications.

Conical internal thread / Conical external thread: Ideal for high-pressure or impact conditions, ensuring a secure, leak-proof seal.

Applications of G and R Pipe Threads

The primary purpose of the R and G threads lies in their sealing and connection roles:

R Thread: Utilized for sealed connections, where the pipe thread acts as a sealing surface. Raw material tape or thread sealants are commonly used to enhance sealing.

G Thread: Used for fastening and connecting components without providing sealing capabilities. Combined gaskets or sealing rings are employed to seal the connection.

Sealing Methods and Global Practices

The sealing methods employed in R and G threaded connections vary by region:

Japan commonly uses taper pipe thread sealing and ensures leak prevention through sealants applied along the raw material tape. High manufacturing precision and assembly accuracy are critical in achieving a leak-free connection.

In Europe and the United States, sealing gaskets are more commonly used, requiring accurate joint surfaces for proper sealing. Gasket-based sealing is easy to install and maintain, but improper assembly or surface imperfections can lead to leakage.

Anaerobic adhesive (such as H-330), used for sealing, is a one-component adhesive that polymerizes when isolated from air. This adhesive is frequently used in sealing and bonding applications in machinery, ensuring enhanced leak-proofing in threaded connections.

Send your message to this supplier

Related Articles from the Supplier

Use and Difference of R and G Pipe Threads

- Dec 14, 2024

Related Articles from China Manufacturers

Fasteners Use in High Temperature and Pressure

- Apr 18, 2023

Use and Maintenance of Plastic Mold Boxes

- Sep 09, 2020

The Use and Maintenance of Pneumatic Valves

- Jun 13, 2022

The Use and Maintenance of Pneumatic Valves

- Feb 27, 2022

The Use And Features of Globe Valve

- Sep 07, 2020

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/use-and-difference-of-r-and-g-pipe-threads.html