Flow Direction Design of Three-Way Ball Valves

A three-way ball valve is an advanced valve type that offers several distinct advantages due to its structural design. Among its key features are low friction during operation, resistance to seal wear, and minimal opening and closing torque. These benefits contribute to the compact size of the actuator, reducing energy consumption and improving efficiency. Additionally, when paired with a multi-rotation electric actuator, a three-way ball valve can precisely control the medium, allowing for tight shut-off and flow regulation. This makes it especially suitable for demanding applications in industries such as petroleum, chemicals, and urban water supply and drainage, where reliable flow control and strict cut-off are essential.Types of

Three-Way Ball Valves

Three-way ball valves come in two main configurations: T-shaped and L-shaped.

1. T-shaped Ball Valve

This type can connect three orthogonal pipelines, allowing for diversion or confluence of the medium. It can also shut off the third channel, enabling efficient flow management between multiple pipelines. T-shaped valves are versatile in applications where the redirection of flow or combining of multiple flow paths is required.

2. L-shaped Ball Valve

The L-shape configuration is designed to connect two mutually orthogonal pipelines. Unlike the T-shaped valve, it cannot maintain interconnection with the third pipeline. It is typically used when only two pathways need to be connected, providing a simple and effective solution for such scenarios.

Key Structures of Three-Way Ball Valves

The primary structural components of a three-way ball valve include the ball, body, and actuator. The ball has a hole or port, which, depending on its orientation, allows flow to either be redirected, combined, or stopped. The actuator, which can be electric or pneumatic, drives the movement of the ball to adjust the flow path. The body houses the ball and provides the necessary seals to prevent leaks.

Working Principle of Pneumatic Three-Way Ball Valves

The pneumatic three-way ball valve operates through the movement of pistons that are powered by air inlets. Here’s a breakdown of the operation:

Valve Opening: The valve opens when two air inlets are activated, causing two pistons to move apart, compressing the spring. This action rotates the output shaft counterclockwise, positioning the ball in the appropriate orientation to allow flow.

Valve Closing: In the event of air or power loss, the spring forces the pistons back toward the center, which causes the ball to rotate clockwise, closing the valve and stopping the flow of the medium.

Flow Direction in Three-Way Ball Valves

The flow direction in a three-way ball valve is determined by the configuration of the valve and the movement of the ball within the body. In the T-shaped valve, the ball is designed to provide the ability to divert or combine flows between three pipelines. The ball port can be adjusted to either block one pathway or allow flow between the remaining two. In the L-shaped valve, the ball’s design only allows for the connection of two pipelines, with no third pathway being maintained.

Conclusion

Three-way ball valves offer versatile flow control solutions, ideal for systems that require the ability to divert or combine flow in complex piping configurations. The L-shaped and T-shaped designs serve different purposes depending on the flow requirements, with the T-shape being more suitable for applications requiring the interconnection of three pipelines. Additionally, their low-friction design, combined with the ability to integrate advanced actuators, ensures precise and reliable operation, making them a crucial component in industries that demand high-performance flow control.

Send your message to this supplier

Related Articles from the Supplier

Flow Direction Design of Three-Way Ball Valves

- Dec 14, 2024

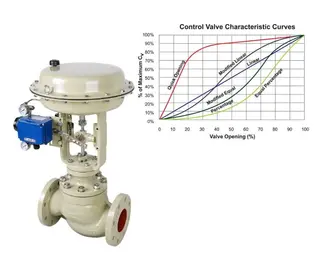

Flow Characteristics of Control Valves

- Oct 14, 2025

Related Articles from China Manufacturers

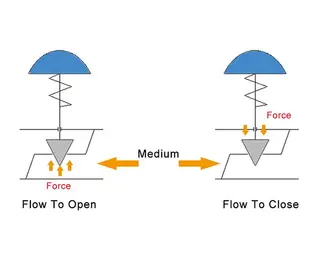

Flow direction of a globe valve

- Sep 16, 2019

The flow direction of globe valves

- Jun 21, 2018

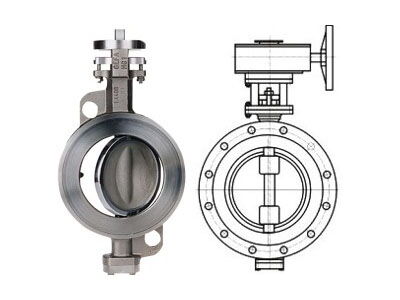

Butterfly Valve Flow Direction and Installation Tips

- Dec 04, 2024

What is Flow Control Valve

- May 11, 2017

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/flow-direction-design-of-three-way-ball-valves.html