Differences Between V-port Ball Valve and Standard Ball Valve?

Ball valve is one of the most common types of valves that are applied in industrial and residential piping systems to control the flow of liquids and gases. Ball valves are classified into standard port and v-port ball valves based on their bore design. In this article, we are going to look at their features and advantages.

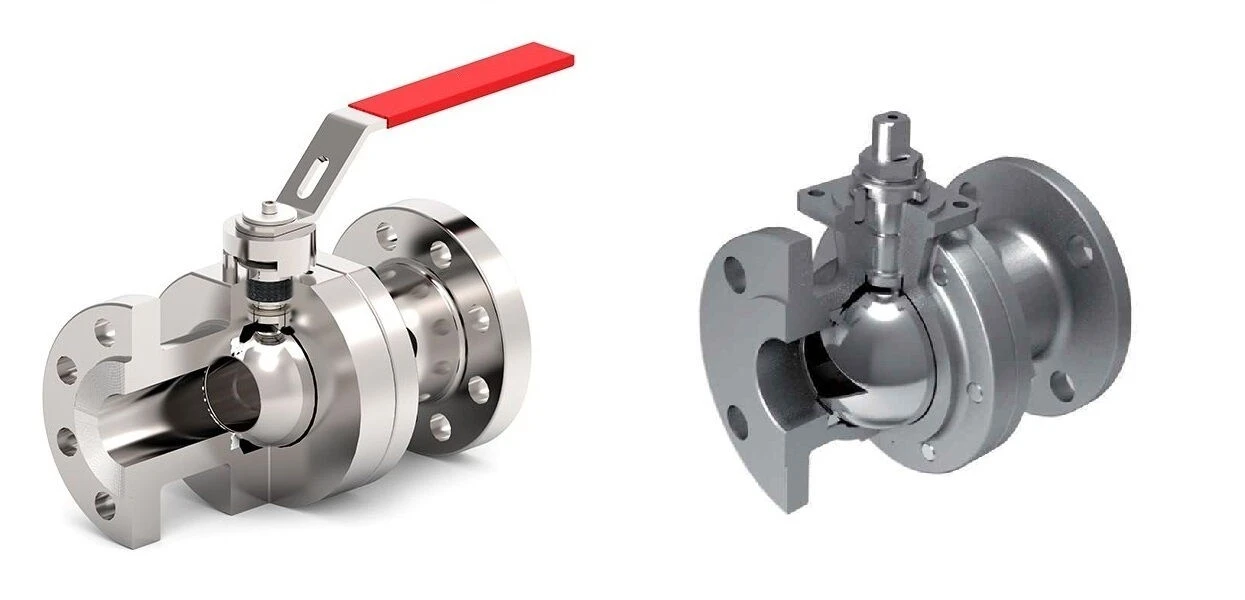

Pics: Standard Ball Valve (O-port Ball) vs. V-Port Ball Valve

Structure:

- Standard ball valve (O-shaped ball): There is a circular passage in the center of the ball. When the valve is fully opened, the diameter of the passage is the same as the inner diameter of the pipe, forming a straight flow channel.

- V-port ball valve: Ball valves with either a V-shaped seat or V-shaped balls are called V-port ball valves.

Flow characteristics:

- Standard ball valve (O-shaped ball) has a nearly quick-opening flow characteristic. When the valve is opened at a small degree (such as 0°-15°), the flow increases very quickly; after reaching a certain degree of opening (usually around 20°-30°), the flow is close to the maximum value (more than 80%-90% of the full-open flow). The main function is switching (cutting off), and the regulating performance is not good.

- V-port ball valve: has an approximately equal percentage flow characteristic. The flow rate changes relatively smoothly and more linearly with the opening (especially in the small opening range). When the opening increases, the flow rate increases in proportion to the opening percentage. Designed for precise regulation control.

Pics: Different V Cut Degree of Ball

Regulation performance:

- Standard ball valve: poor regulation performance. The flow rate changes too dramatically at small openings and is difficult to control accurately; at medium openings (the edge of the ball hole partially blocks the flow channel), the flow characteristics are unstable, prone to cavitation, vibration and noise; usually only used for on/off two-position control.

- V-port ball valve: excellent regulation performance. The V-shaped cutout design enables it to provide stable and predictable flow control at small openings, and can achieve good linear regulation over the entire opening range. The V-shaped edge has a shearing effect on the fluid, which is particularly suitable for controlling media containing fibers, particles or slurries.

Cut-off performance:

- Standard ball valve: very good cut-off ability. When the valve is closed (the ball rotates 90°), the complete spherical surface completely blocks the flow channel, and with soft seals or metal seals, bubble-level sealing (zero leakage) can be achieved.

- V-port ball valve: relatively weak cut-off ability. Even in the fully closed position, the smallest point of the V-shaped cut cannot completely form a sealing surface like an O-shaped ball (it is more like a sharp blade pressing on the valve seat). Although it can also achieve a higher sealing level (usually level VI or level V), it is theoretically not as good as the zero leakage performance of the same specification O-shaped ball valve. Its design focuses on adjustment rather than absolute cut-off.

Flow resistance:

- Standard ball valve: extremely low flow resistance when fully open (small flow resistance coefficient), close to a straight pipe, and very little pressure loss.

- V-type ball valve: Even in the fully open position, the presence of the V-shaped cut will produce a certain flow resistance, and the pressure loss is greater than that of the same specification Standard ball valve.

Anti-scouring and wear resistance (for media containing solid particles):

- Standard ball valve: During the switching process, especially when the medium contains solid particles, the particles are easily stuck between the ball and the valve seat, causing scratches, wear and even jamming of the sealing surface. Poor wear resistance and anti-scouring.

- V-port ball valve: The sharp edge of the V-shaped cutout has a shearing effect on the fibers and solid particles in the fluid during the adjustment process, which can effectively prevent blockage. The design is more suitable for handling dirty media with high viscosity, easy crystallization or easy scaling, such as solid particles, fibers, slurry, etc., with good wear resistance and anti-scouring.

Applicable working conditions:

- Standard ball valve: Mainly used in occasions that require fast and reliable cutting. Suitable for clean liquids and gases (such as oil, natural gas, water, steam, etc.). It is the first choice for switch valves.

- V-port ball valve: Mainly used in occasions that require precise flow regulation and control. Especially suitable for media containing solid particles, fibers, slurry, high viscosity fluids, and media that are easy to scale and crystallize (such as pulp, sewage, slurry, mud, chemical raw materials, etc.). It is one of the first choices for regulating valves.

Price:

Generally, since the ball processing of V-port ball valve is more complicated (precise processing of V-shaped mouth is required), its price is higher than that of Standard ball valve of the same specifications and materials.

How to choose?

Need a reliable shutoff? -> Choose an O-shaped ball valve.

Need precise flow regulation? -> Choose V-port ball valve.

Clean media? -> Both are OK (choose according to functional requirements).

Does the media contain particles, fibers, viscosity, and easy to scale? -> V-port ball valve is preferred.

Limited budget and only need to open and close? -> Choose an O-shaped ball valve.

Simply put, the O-shaped ball valve is an expert in opening and closing (closes tightly), and the V-port ball valve is an expert in regulating (controls accurately and is not afraid of dirt). Which one to choose depends on whether your core requirement is shutdown or regulation, as well as the characteristics of the media.

Send your message to this supplier

Shanghai Shinjo Valve Co., Ltd.

- http://www.shinjovalve.com/

- Address: 上海

- Phone: 13122293865

- Business Type: Manufacturer,

Supplier Website

Source: https://www.shinjovalve.com/news/differences-between-v-port-ball-valve-and-standard-ball-valve.html