How Cam Locks Keep Lockers Secure: A Look Inside the Design and Function

Introduction

In modern workplaces, schools, gyms, and retail environments, lockers are essential for keeping personal belongings safe. Yet, the small metal component that keeps a locker door securely closed often goes unnoticed—the cam lock. Compact, efficient, and easy to use, cam locks are among the most widely used locking mechanisms for locker systems around the world.

Whether it’s securing employee valuables in an office, protecting students’ items in a school, or ensuring safe storage in a fitness center, cam locks provide a simple, reliable, and cost-effective solution for light- to medium-security applications. Their durability, adaptability, and ease of installation make them a cornerstone of everyday security systems.

This article explores how cam locks work, their internal components, variations in size and function, and why they continue to be the lock of choice for locker manufacturers and facilities managers alike.

What Is a Cam Lock?

A cam lock is a type of fastener that uses a rotating cam—a flat or curved metal plate—attached to the rear of the lock body. When a key or actuator turns the lock, the cam rotates behind the locker door or panel, engaging or disengaging with a strike plate or locking frame.

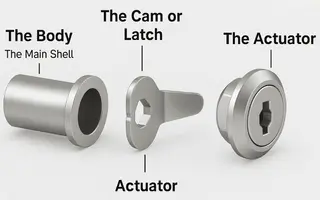

Simple in design yet highly functional, cam locks are used in countless applications beyond lockers, including mailboxes, cabinets, vending machines, and enclosures. Their versatility lies in their modular structure—comprising a lock body, a cam, and an actuator—that can be customized to fit different materials, panel thicknesses, and operational requirements.

At its core, the cam lock provides mechanical security through motion. When the user inserts a key and rotates it, the cam swings into position, physically blocking the door from opening. Turning the key in the opposite direction retracts the cam, allowing access.

This straightforward mechanism makes the cam lock one of the most efficient and affordable locking solutions available.

Main Components of a Cam Lock

While the design may seem simple, each part of a cam lock plays a vital role in ensuring reliable function, smooth operation, and resistance to tampering. Understanding these components helps in selecting the right model for specific locker systems.

1. The Lock Body: The Foundation

The body—sometimes called the housing or barrel—is the main cylindrical section of the lock that fits into the locker or cabinet wall. It holds the locking mechanism and provides the structure that supports the actuator and cam.

Although it may appear to be just a piece of metal, precision is essential. The body must be the correct length to match the panel’s thickness. If it’s too short, the cam may not fully engage with the frame, compromising security. Too long, and the lock may feel loose or protrude awkwardly.

Manufacturers typically make lock bodies from zinc alloy, stainless steel, or brass, depending on corrosion resistance and strength requirements. For lockers located in humid environments, such as gyms or swimming pool facilities, stainless steel bodies are particularly popular due to their rust resistance and long service life.

2. The Cam (or Latch): The Locking Arm

The cam is the flat metal arm mounted on the rear of the lock body. This is the component that physically holds the door shut. When the key is turned, the cam rotates, engaging with the locker frame or disengaging to allow the door to open.

Cams come in various shapes and sizes—straight, offset, hooked, or custom—to fit specific locking applications. The length of the cam determines how far it swings and how securely it engages the frame.

This part is often made from hardened steel or nickel-plated zinc for durability and strength. The cam’s motion is what transforms the lock from a passive mechanism into an active security device.

3. The Actuator: The User Interface

The actuator is the part of the cam lock that the user interacts with—it could be a keyhole, a knob, or a push-button. Its function is to transfer motion from the user to the internal mechanism.

In traditional locker cam locks, this means inserting and turning a key. However, modern designs may incorporate digital keypads, RFID readers, or electronic actuators, turning the mechanical cam lock into a hybrid or fully electronic security device.

High-quality actuators are engineered for smooth rotation, precise key engagement, and resistance to wear over thousands of cycles. In busy locker environments, this durability is crucial for maintaining user satisfaction and reducing maintenance costs.

How Do Cam Locks Work?

At its simplest, a cam lock operates by rotational motion. When the key is inserted and turned—usually 90° or 180°—the cam attached to the rear of the lock body rotates with it.

In the locked position, the cam engages with the frame or strike plate, preventing the door from opening. When turned in the opposite direction, the cam swings clear of the frame, releasing the door.

The operation can be either clockwise or counterclockwise, depending on how the cam is installed and the locker’s configuration.

For added security, many cam locks use a key retention system, meaning the key cannot be removed unless the lock is in a specific position—usually locked. This feature helps prevent users from accidentally leaving lockers unlocked.

Types and Sizes of Cam Locks

Not all cam locks are created equal. They vary by size, cam shape, key type, and security level to suit different environments and cabinet constructions.

One of the most critical factors in choosing a cam lock is the cylinder length, which must correspond to the locker’s panel thickness. The correct fit ensures both smooth operation and reliable locking performance.

Here are the most common cam lock sizes used for lockers and similar applications:

5/8″ Locks: Ideal for thin panels (up to about 3/8″ thick). Commonly found in lightweight office furniture, mailboxes, and metal filing drawers.

7/8″ Locks: The most widely used “middle ground” size. Suitable for desks, cabinets, and locker doors up to about 5/8″ thick.

1-1/8″ Locks: Designed for thicker panels (up to about 7/8″), making them a popular choice for gym lockers, vending machines, and server cabinets.

1-3/8″ and Larger: Used in heavy-duty industrial applications where the door material is thick or reinforced.

Each of these dimensions refers to the cylinder length, not the entire lock body. Selecting the correct length ensures that the cam engages securely with the frame and that the lock installs flush with the locker surface.

Cam Lock Materials and Finishes

The durability and appearance of a cam lock depend heavily on its material and surface finish. Common materials include:

Zinc Alloy: Lightweight, cost-effective, and corrosion-resistant. Ideal for general-purpose lockers and cabinets.

Stainless Steel: Offers superior corrosion resistance, perfect for humid or marine environments.

Brass: Provides high mechanical strength and smooth key action, often used in premium applications.

Surface finishes such as chrome plating, nickel plating, or powder coating enhance corrosion resistance and aesthetics. Chrome finishes, in particular, provide a sleek appearance suitable for modern locker designs.

Security Options for Cam Locks

While traditional cam locks use a standard mechanical key, various security enhancements have been developed to meet the needs of modern facilities.

Keyed Alike and Keyed Different Systems

Keyed Alike: Multiple locks use the same key. Convenient for facility managers or maintenance teams who need access to many lockers.

Keyed Different: Each lock has its own unique key, enhancing individual security for users.

Many locker systems use a master key system, allowing management to open all lockers even if individual keys are lost.

Tubular and Disc Tumbler Mechanisms

Cam locks can use different internal mechanisms. The most common are:

Flat Key (Pin Tumbler): Traditional design using standard keys.

Tubular Key: Features a round key and offers better resistance to picking.

Disc Tumbler (Wafer): Provides high durability and smooth operation, often used in modern furniture and lockers.

Installation and Maintenance

Installing a cam lock is relatively straightforward, which is one reason it remains so popular. A typical installation requires drilling a circular hole in the locker panel, inserting the lock body, and securing it with a nut or clip. The cam is then attached to the rear using a screw or retaining ring.

Regular maintenance involves:

Cleaning and lubricating the cylinder to prevent jamming.

Checking cam alignment to ensure the lock engages fully.

Inspecting for corrosion or wear, particularly in humid or outdoor environments.

Replacing a cam lock is simple—usually requiring only a screwdriver and a few minutes. This makes maintenance cost-effective and reduces downtime in locker rooms or public facilities.

Advantages of Cam Locks for Lockers

Cam locks continue to dominate the locker security market for several key reasons:

Simplicity: Easy to install, operate, and maintain.

Affordability: Cost-effective even for large locker installations.

Versatility: Available in a wide range of sizes, finishes, and keying options.

Durability: Built from metal components that withstand frequent use.

Customizability: Compatible with both mechanical and electronic systems.

Whether used in a school hallway or a high-end fitness center, cam locks deliver dependable performance and consistent security.

Modern Innovations: Smart Cam Locks

With the rise of digital transformation in facility management, traditional cam locks are evolving. Modern “smart” cam locks integrate electronic access control technologies, such as RFID cards, PIN codes, or mobile app connectivity.

These locks maintain the familiar mechanical cam mechanism but replace the key cylinder with an electronic actuator. Benefits include:

Keyless entry: Users can unlock lockers using cards or smartphones.

Access tracking: Facilities can monitor when lockers are opened.

Remote management: Administrators can program or disable locks without physical keys.

Hybrid models are gaining traction in gyms, co-working spaces, and smart buildings, offering the perfect blend of traditional reliability and modern convenience.

Applications Beyond Lockers

While lockers are the most visible use, cam locks are also essential in many other industries:

Vending Machines: To secure cash and inventory compartments.

Electrical Enclosures: To prevent unauthorized access to panels.

Mailboxes and Parcel Lockers: To safeguard personal correspondence.

Industrial Cabinets: For securing tools, parts, and safety equipment.

The same fundamental design has been adapted for different scales and security levels, from small drawer locks to heavy-duty enclosures.

Conclusion

The cam lock’s enduring popularity comes from its perfect balance of simplicity, reliability, and adaptability. It’s a modest component that plays a crucial role in everyday security—quietly ensuring that personal belongings, tools, and documents remain protected.

As locker systems evolve to meet modern needs, cam locks continue to evolve with them. From traditional keyed mechanisms to smart, networked solutions, their core purpose remains the same: to keep what’s inside safe, secure, and accessible only to those authorized to open it.

For manufacturers, facility managers, and users alike, the cam lock represents a time-tested combination of mechanical precision and practical design—a small but indispensable part of daily life.

Send your message to this supplier

Related Articles from the Supplier

How do Tubular Cam Locks Work to Ensure Security?

- Aug 01, 2019

How To Measure Cam Locks

- Dec 11, 2014

How to Protect the Mailbox with Tubular Cam Locks?

- Dec 27, 2021

Related Articles from China Manufacturers

How to Assemble Furniture with Cam Locks - Part One

- Mar 18, 2023

How to Maintain Cam Locks?

- Mar 31, 2021

How to Replace Cam Locks and Its Production Process

- Jun 29, 2023

How to Measure Cam Locks?

- Jan 03, 2017

How to Open Cam Locks?

- Nov 29, 2023

Related Products Mentioned in the Article

Supplier Website

Source: https://www.makelocks.com/news/how-cam-locks-keep-lockers-secure-a-look-inside-the-design-and-function.html