Valve Corrosion Prevention: Strategy to Combat Medium Corrosion

In industrial production, valves are indispensable key components, much like the joints in the human body, controlling the flow of fluids. However, during use, valves are often threatened by the corrosion of various media, which not only affects their normal operation but can also lead to serious safety accidents. Therefore, understanding and mastering the scientific methods of valve corrosion prevention is crucial for ensuring the smooth progress of industrial production.

The Complexity of Medium Corrosion

In practical use, the corrosion of media in valves is extremely complex. Even if the valve material is the same, different concentrations, temperatures, and pressures of the media can lead to vastly different degrees of corrosion. For example, for every 10°C increase in medium temperature, the corrosion rate approximately increases by 1 to 3 times. This is similar to how chemical reactions speed up in high-temperature environments, leading to more rapid corrosion.

The impact of medium concentration on the corrosion of valve materials is even more pronounced. Take lead, for example. In dilute sulfuric acid, the corrosion of lead is minimal and almost negligible. However, when the concentration of sulfuric acid exceeds 96%, the corrosion of lead increases sharply. Carbon steel, on the other hand, behaves differently. It is most severely corroded when the sulfuric acid concentration is around 50%, but the corrosion decreases sharply when the concentration increases to above 6%. This illustrates that different materials exhibit completely different corrosion behaviors in media of different concentrations.

Aluminum is highly corrosive in concentrated nitric acid with a concentration of over 80%, but it is less corrosive in medium and low concentrations of nitric acid. Stainless steel has strong corrosion resistance to dilute nitric acid, but its corrosion increases in concentrated nitric acid with a concentration of over 95%. These examples fully demonstrate that the complexity of medium corrosion requires us to consider various factors comprehensively when selecting valve materials and corrosion prevention measures, rather than adopting a one-size-fits-all approach.

Corrosion Prevention Treatment of Valve Components

When facing complex medium corrosion environments, targeted corrosion prevention treatment of various valve components is particularly important. As we mentioned earlier, the corrosion characteristics of media change with temperature, concentration, pressure, and other factors. This means that we cannot rely solely on the inherent corrosion resistance of valve materials but also need to enhance their corrosion resistance through various surface treatment processes. Next, we will explore in detail the corrosion prevention methods for different valve components, which can not only effectively resist corrosion but also improve the overall performance and service life of the valve.

1. Corrosion Prevention of Valve Connection Bolts

Valve connection bolts are an important part of the valve and need to have good resistance to atmospheric and medium corrosion. To achieve this, bolts are usually treated with surface processes such as galvanizing, chrome plating, and oxidation (bluing). These treatments can effectively form a protective film on the surface of the bolt, preventing direct contact between the corrosive medium and the bolt, thereby extending the service life of the bolt.

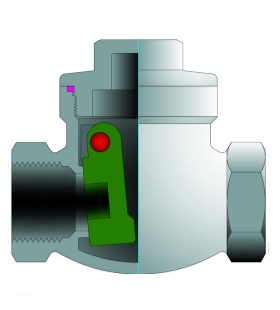

2. Corrosion Prevention of Sealing Surfaces and Closing Elements

Sealing surfaces and closing elements with small diameters are key parts of the valve, and their corrosion and wear resistance directly affect the sealing performance of the valve. To improve the performance of these components, surface processes such as nitriding and boriding are often used. For example, the nitriding layer thickness of a valve disc made of 38CrMoAlA is usually required to be more than 0.4mm. Such surface treatment can significantly enhance the corrosion and wear resistance of the valve disc, enabling it to work stably for a long time in complex medium environments.

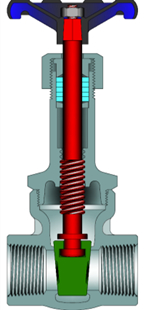

3. Corrosion Prevention of Valve Stems

The valve stem is another component of the valve that is prone to corrosion. To improve the corrosion and wear resistance of the valve stem, surface treatment processes such as nitriding, boriding, chrome plating, and nickel plating are widely used. Different surface treatment methods are suitable for different valve stem materials and working environments. For example, for valve stems in contact with air, steam, and asbestos packing, hard chrome plating and gas nitriding processes can be used (ion nitriding process is not suitable for stainless steel); for valve stems in a hydrogen sulfide atmosphere, electroplating with high-phosphorus nickel plating provides good protective performance; 38CrMoAlA can be made corrosion-resistant by ion and gas nitriding, but hard chrome plating is not suitable; 2Cr13, after quenching and tempering, can resist ammonia gas corrosion, and carbon steel treated with gas nitriding can also resist ammonia corrosion, while all phosphorus-nickel platings are not resistant to ammonia corrosion. 38CrMoAlA material, after gas nitriding treatment, has good corrosion resistance and comprehensive performance, so it is commonly used to make valve stems.

4. Corrosion Prevention of Small-Diameter Valve Bodies and Handwheels

Although small-diameter valve bodies and handwheels are small in size, they also need to be treated for corrosion prevention. They are usually chrome-plated, which not only improves their corrosion resistance but also decorates the valve, making its appearance more aesthetically pleasing.

Application of Thermal Spraying Technology in Valve Corrosion Prevention

Thermal spraying is a coating preparation process and has become one of the new technologies for material surface protection. It uses high-energy-density heat sources (such as gas combustion flames, electric arcs, plasma arcs, electric heating, gas detonation, etc.) to heat and melt metal or non-metal materials, which are then sprayed onto the pre-treated substrate surface in a which are then sprayed onto the pre-treated substrate surface in a atomized form, forming a sprayed coating, or simultaneously heating the substrate surface to remelt the coating on the substrate surface, forming a sprayed welding layer, which is a surface strengthening process method.

The advantage of thermal spraying technology is that it can use a variety of materials, including most metals and their alloys, metal oxide ceramics, metal ceramic composites, and hard metal compounds. These materials can be applied to metal or non-metal substrates through different thermal spraying methods to form coatings. The coatings formed by thermal spraying can significantly improve the substrate surface's corrosion resistance, wear resistance, and high-temperature resistance, thereby extending the service life of equipment.

In addition to improving corrosion resistance, thermal spraying can also be used to prepare coatings with special functions. For example, coatings with special properties such as thermal insulation, electrical insulation (or electrical isolation), grindable sealing, self-lubrication, thermal radiation, and electromagnetic shielding can be prepared. Moreover, thermal spraying technology can also be used for the repair of parts, which has important practical significance in industrial production.

The Role of Coatings in Valve Corrosion Prevention

Coatings are a widely used corrosion prevention method and are indispensable corrosion prevention materials and identification marks for valve products. Coatings are non-metallic materials, usually formulated from synthetic resins, rubber emulsions, vegetable oils, solvents, etc. They work by covering the metal surface to isolate the medium and the atmosphere, achieving the purpose of corrosion prevention.

Coatings are mainly used in environments with less severe corrosion, such as water, brine, seawater, and the atmosphere. The inner cavity of the valve is often painted with anti-corrosion paint to prevent corrosion of the valve by water, air, and other media. In addition, different colors can be added to the paint to indicate the material used for the valve. Generally, the painting cycle for valves is once every six months to one year to ensure its corrosion prevention effect.

Electrochemical Protection Technology

Electrochemical protection is an effective corrosion prevention method, which is divided into anodic protection and cathodic protection. Anodic protection involves making the metal an anode to form a protective film on its surface, thereby achieving corrosion prevention. However, anodic protection is less commonly used in actual production. In contrast, cathodic protection is more widely applied.

The principle of cathodic protection is to make the metal a cathode to prevent it from being corroded. For example, when zinc protects iron, zinc acts as the sacrificial metal that corrodes, thereby protecting the iron. In the corrosion prevention of large and important valves, using the cathodic protection method is an economical, simple, and effective approach. In addition, adding zinc to asbestos packing to protect the valve stem also falls under the cathodic protection method.

The Importance of Controlling the Corrosion Environment

The term "environment" has both broad and narrow meanings. The broad environment refers to the surroundings where the valve is installed and the media flowing inside it; the narrow environment refers to the conditions around the valve installation site. In most cases, the environment is uncontrollable, and the production process cannot be changed arbitrarily. However, when it does not harm the product or process, methods to control the environment can be used to slow down corrosion.

For example, removing oxygen from boiler water and adjusting the pH value with alkali in the refining process are effective methods to control the corrosion environment. In addition, adding corrosion inhibitors and using electrochemical protection also fall under the category of controlling the corrosion environment.

In actual production environments, the atmosphere is filled with dust, water vapor, and smoke, especially in environments with toxic gases and fine powders emitted from chimneys and equipment, all of which can cause varying degrees of corrosion to valves. Therefore, operators should follow the regulations in the operating procedures to regularly clean, blow, and oil the valves, which are effective measures to control environmental corrosion.

Moreover, installing protective covers on valve stems, setting up sumps for ground valves, and painting the valve surface are all methods to prevent corrosive substances from eroding the valves. An increase in environmental temperature and air pollution, especially for equipment and valves in enclosed environments, can accelerate their corrosion. Therefore, it is advisable to use open workshops or take ventilation and cooling measures to slow down environmental corrosion.

Conclusion

Valve corrosion prevention is a systematic project that requires a comprehensive consideration of various factors, including the corrosion characteristics of the media, the materials of the valve components, and the working environment. By adopting appropriate surface treatment processes, thermal spraying technology, coating protection, electrochemical protection, and controlling the corrosion environment, the corrosion resistance of valves can be effectively improved, their service life can be extended, and the smooth progress of industrial production can be ensured. In practical applications, reasonable selection and combination should be made according to specific conditions to achieve the best corrosion prevention effect.

Send your message to this supplier

Related Articles from the Supplier

Valve Leakage and Maintenance Measures

- Feb 05, 2025

Valve Sealing Principles and Influencing Factors

- Feb 20, 2025

Guide to Valve Performance and Selection

- Oct 10, 2025

Related Articles from China Manufacturers

The corrosion prevention of metal valves - part one

- Jul 01, 2019

Corrosion Prevention Strategies for Metal Valves

- Aug 23, 2025

The corrosion prevention of metal valves - part two

- Jul 01, 2019

Measures for Preventing Metal Valves from Corrosion

- Apr 15, 2024

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/valve-corrosion-prevention-strategy-to-combat-medium-corrosion.html