Guide to Aluminum Alloy Forging Technology

In today's industrial manufacturing field, aluminum alloys have become indispensable materials in aerospace, automotive manufacturing, electronics, and telecommunications industries due to their lightweight, high strength, excellent electrical conductivity, and corrosion resistance. Many of these superior properties are largely attributed to advanced forging technologies. This article will provide an in-depth exploration of various aluminum alloy forging processes, their characteristics, and applications, helping you better understand this key manufacturing technology.

Overview of Aluminum Alloy Forging

Aluminum alloy forging is a processing method that applies external force to aluminum alloy materials to induce plastic deformation, thereby achieving the desired shape and dimensions. Depending on different processing methods and equipment, aluminum alloy forging processes can be categorized into open-die forging, die forging, ring rolling, and special forging. Each process has its unique characteristics and application scenarios, which will be introduced in detail below.

Open-Die Forging: Basic and Flexible Process

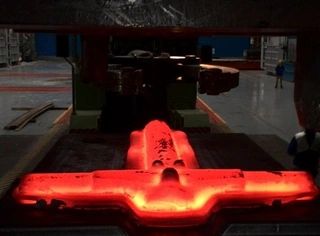

Open-die forging is the most basic and commonly used aluminum alloy forging process. It utilizes simple universal tools or directly applies force to the billet between the upper and lower anvils of forging equipment to produce deformation, thereby obtaining the required geometry and internal quality of the forged part. Open-die forging is primarily used for low-volume production, using forging hammers, hydraulic presses, and other equipment to shape billets.

The basic operations of open-die forging include upsetting, elongating, punching, cutting, bending, twisting, shifting, and forging joints. It is usually performed as hot forging to ensure the material's plasticity and deformability. Hot forging enhances the ductility of aluminum alloys, making them easier to deform and reducing internal defects. The advantages of open-die forging are its high flexibility, the ability to adjust processing methods as needed, and suitability for producing complex-shaped, large-size forged parts. However, its precision is relatively low, and production efficiency is not as high as die forging.

Die Forging: Combining High Precision and High Efficiency

Die forging is a process in aluminum alloy forging with relatively high precision and production efficiency. It involves placing a metal billet into a die cavity of a specific shape and then applying pressure to deform it, obtaining a forged part of the desired shape. Die forging can be divided into open-die and closed-die forging, as well as hot, warm, and cold forging.

1. Open-Die Forging vs. Closed-Die Forging

Open-die forging allows metal to flow freely within the die cavity without being restricted by the cavity boundaries. This process is suitable for producing simple-shaped, small-sized forged parts. Closed-die forging occurs within a fully enclosed die cavity, restricting metal flow and thereby achieving higher precision and better surface quality. Closed-die forging and closed-die upsetting are favored because they produce no flash, have high material utilization, and can complete precision finishing of complex forged parts.

2. Hot, Warm, and Cold Die Forging

Hot die forging is performed at higher temperatures, typically between 350°C and 450°C. This process improves the plasticity and deformability of aluminum alloys and is suitable for producing complex-shaped, large-size forged parts. Warm forging is conducted at lower temperatures, generally between room temperature and the recrystallization temperature. Warm forging reduces energy consumption, improves production efficiency, and also achieves good surface quality and dimensional accuracy. Cold forging is conducted at room temperature, suitable for producing simple-shaped, small-size forged parts. Cold forging increases material strength and hardness but requires higher die quality.

Warm forging and cold forging reflect the level of forging technology and represent the future development direction of die forging processes. With technological advances, warm and cold forging applications in aluminum alloy forging are becoming increasingly widespread, especially in aerospace and automotive manufacturing.

Ring Rolling: Efficient Production of Circular Parts

Ring rolling is a forging process specifically used for producing ring-shaped parts. It uses specialized ring-rolling equipment to continuously apply local plastic deformation to aluminum alloy billets, achieving the required diameter and thickness of the rings. The ring-rolling process is particularly suitable for producing large ring-shaped parts such as automotive wheels and train wheels, offering high production efficiency, high material utilization, and low cost.

Although the ring-rolling process is relatively simple, it requires precise control of equipment and process parameters. By accurately controlling the rolling machine's speed, pressure, and feed rate, the quality and dimensional accuracy of ring-shaped parts can be ensured. Additionally, ring rolling can be combined with other forging processes, such as open-die forging and die forging, to produce more complex ring-shaped parts.

Special Forging Processes: Meeting Special Requirements

In addition to open-die forging, die forging, and ring rolling, aluminum alloy forging also includes some special forging processes, such as roll forging, wedge rolling, radial forging, and liquid die forging. These special forging processes are suitable for producing parts with unique shapes, offering unique advantages and broad application prospects.

1. Roll Forging

Roll forging is a process in which a pair of rotating rolls continuously deforms the billet. Roll forging can serve as an effective preforming process, significantly reducing the forming pressure required for subsequent steps. It is suitable for producing regular-shaped, large-size parts, such as shafts and tubular components. The advantages of roll forging include high production efficiency, high material utilization, and the possibility of automated production.

2. Wedge Rolling

Wedge rolling is a forging process that applies transverse rolling to the billet using a wedge-shaped die. It is suitable for producing components such as steel balls and drive shafts. The advantages of wedge rolling include high production efficiency, high dimensional accuracy, and the ability to achieve continuous production. By precisely controlling the rolling parameters, the quality and performance of parts can be ensured.

3. Radial Forging

Radial forging is a process that deforms the billet using radial forces. It is suitable for producing large forgings such as gun barrels and stepped shafts. The advantages of radial forging include high production efficiency, high material utilization, and the ability to process complex shapes. By accurately controlling forging parameters, the quality and performance of forged parts can be ensured.

4. Liquid Die Forging

Liquid die forging is a process in which forging is carried out in molten metal. The molten metal is injected into a die cavity, and pressure is applied to solidify it into the desired shape. The advantages of liquid die forging include high production efficiency, high dimensional accuracy, and the ability to produce complex shapes. It is suitable for producing complex, small-size components such as aerospace parts and electronic components.

Characteristics of Aluminum Alloy Forging

Aluminum alloy forging processes have a series of unique characteristics, which impose higher requirements on forging equipment and process control. Understanding these characteristics can help in selecting and optimizing forging processes.

Narrow Forging Temperature Range: Aluminum alloys have a narrow deformation temperature range, mostly between 350°C and 450°C, with a deformation window of about 100°C, and some alloys as narrow as 50–70°C. This makes the forging operation window short and requires strict control of heating and forging temperatures. Excessively high or low temperatures will reduce material plasticity, increase forging difficulty, and raise the risk of defects.

Strain Rate Sensitivity: Aluminum alloys are sensitive to strain rates, requiring low-speed and stable forging equipment. High strain rates can lead to stress concentration and increased risk of cracking. Therefore, low-speed, stable equipment is preferred to ensure process stability and quality.

Good Thermal Conductivity but High Friction: Aluminum alloys have good thermal conductivity, but high friction, poor flow, and strong adhesion. These characteristics can cause sticking and friction during forging, reducing surface quality and increasing die wear. Appropriate lubricants, anti-adhesion coatings, and optimized process parameters are necessary to improve material flow and surface quality.

Crack Sensitivity: Aluminum alloys are highly sensitive to cracks. Even minor cracks can propagate during subsequent processing and use, leading to part failure. Therefore, forging parameters must be strictly controlled, and molds and equipment should be regularly inspected to ensure smooth, defect-free surfaces, minimizing crack formation.

Applications of Aluminum Alloy Forging

Aluminum alloy forging processes are widely applied in aerospace, automotive manufacturing, and electronics and telecommunications. Below is a detailed overview of applications in each field.

1. Aerospace

In aerospace, aluminum alloys are used to manufacture aircraft structures, engine components, wings, and fuselage parts due to their lightweight, high strength, electrical conductivity, and corrosion resistance. Open-die and die forging are commonly used. Open-die forging produces large structural components such as wing beams and fuselage frames, while die forging produces complex, high-precision parts such as engine blades and turbine disks. Precise forging ensures the quality and performance of components to meet stringent aerospace requirements.

2. Automotive

Aluminum alloys are increasingly used in automotive manufacturing. Forging processes produce engine components, transmission parts, wheels, and suspension systems. Open-die forging is used for simple-shaped, large-size parts such as engine blocks and transmission housings, while die forging produces complex, high-precision components such as crankshafts, connecting rods, and gears. Aluminum forging reduces vehicle weight, improves fuel efficiency, and enhances vehicle safety and reliability.

3. Electronics and Telecommunications

Aluminum alloys are key materials for manufacturing mobile phone housings, computer cases, and communication base station components due to their lightweight, high strength, electrical conductivity, and corrosion resistance. Forging plays an important role in producing structural and functional components in these industries.

Conclusion

Aluminum alloy forging holds an irreplaceable position in modern industry. With continuous technological advancements and evolving market demands, aluminum alloy forging processes will continue to develop and improve. Future trends include automation, intelligence, green manufacturing, high performance, and multi-process integration, providing strong support for high-quality development in aerospace, automotive manufacturing, and electronics industries.

In summary, aluminum alloy forging is not only an important metalworking technology but also a constantly evolving field. By thoroughly understanding its characteristics and applications, we can better select and optimize forging processes, improve product quality and production efficiency, and meet the stringent requirements of modern industry.

Send your message to this supplier

Related Articles from the Supplier

Guide to Aluminum Alloy Forging Technology

- Nov 13, 2025

A Comprehensive Guide to Aluminum Forgings

- Jul 25, 2024

Guide to Non-Ferrous Metal Forging Process

- Nov 06, 2025

A Guide to Non-Ferrous Alloy Casting

- Jun 27, 2025

The Buyers’ Guide on Forging Components

- Dec 24, 2014

Related Articles from China Manufacturers

Guide to Liquid Die Forging Technology

- May 20, 2025

Guide to Nickel-Based Alloy Open Die Forging

- Dec 09, 2025

Guide to Multi-Directional Die Forging Technology

- Feb 04, 2026

Guide to Industrial Valve Repair and Maintenance

- Jan 24, 2025

Guide to Pipe Bend Manufacturing Processing

- Sep 03, 2025

Guide to Selecting Circular Knitting Machine Needles

- Dec 01, 2023

Related Products Mentioned in the Article

Supplier Website

Source: https://www.forging-casting-stamping.com/guide-to-aluminum-alloy-forging-technology.html

![A Guide to Computer User Support for Help Desk [Book]](https://img.jeawincdn.com/resource/upfiles/153/images/products/custom-full-color-printing/custom-catalogs/resize/3f25b1a83689330016a4063627d10c04/CC002-A-Guide-to-Computer-User-Support-for-Help-Desk-Book-320x320.webp)