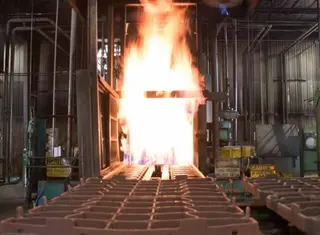

Annealing Process of Cast Steel Components

In the casting industry, the production of large cast steel components is a complex and precise process. After casting, internal stresses, uneven hardness, and other issues often exist within the casting. If left untreated, these problems can cause various issues during subsequent machining and service, such as deformation or cracking. Therefore, the annealing process has become a key step in improving the performance of cast steel components. This article will provide a detailed introduction to several common annealing methods for cast steel parts, as well as safety considerations and process details during annealing.

Basic Principles of Annealing

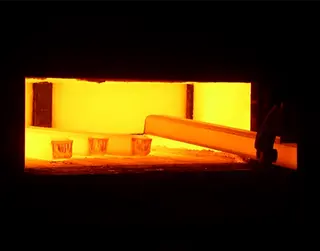

Annealing is a metal heat treatment process in which the metal is slowly heated to a certain temperature, held for a sufficient period, and then cooled at an appropriate rate. The main purpose of this process is to relieve internal stresses, reduce hardness, and homogenize chemical composition and microstructure, thereby effectively improving the performance of castings.

In practice, after the casting is heated to the proper temperature, it is held for a certain period and then allowed to cool naturally. The phase transformation points Ac1, Ac3, and Accm involved in the annealing process are critical temperatures for steel under actual heating conditions. These temperatures determine the specific operating temperature for annealing.

Common Annealing Methods for Castings

There are many types of annealing processes for castings, each suitable for different casting materials and requirements. Understanding the principles and applicable range of these methods is crucial for optimizing casting performance. The following are several common annealing methods for cast steel.

1. Full Annealing

Full annealing involves heating the casting to 20–30°C above Ac3, holding it for a period, and then cooling slowly (usually furnace cooling) to achieve a near-equilibrium microstructure. This method is suitable for medium-carbon and low- to medium-alloy steel castings, forgings, and hot-rolled profiles, and sometimes for their welded components. In actual production, to improve efficiency, large cast steel manufacturers often remove the casting from the furnace when it cools to around 500°C and let it cool in air naturally. Full annealing effectively reduces the hardness of castings, making them easier to machine while also homogenizing chemical composition and microstructure, enhancing overall performance.

2. Homogenization Annealing

The main purpose of homogenization annealing is to equalize the composition and structure of the casting. This method is particularly suitable for high-quality alloy castings or alloy steel castings with severe segregation. During heating, the casting is brought to a high temperature to allow sufficient diffusion of alloying elements, thereby eliminating segregation. After homogenization annealing, the casting exhibits more stable performance and can meet requirements for high precision and high performance.

3. Stress-Relief Annealing

Stress-relief annealing is a treatment aimed at relieving internal stresses in castings. Uneven wall thicknesses can generate thermal and structural stresses during heating, cooling, and phase transformations. In addition, large parts may retain internal stress after machining. If these internal stresses are not eliminated, they can cause deformation or cracking during subsequent machining or service. Stress-relief annealing involves heating the casting to 500–650°C, below Ac1, holding it, and then cooling with the furnace. Typical heating temperatures are 500–550°C, with holding times of 2–8 hours. This method can relieve 90–95% of internal stresses without altering the cast iron microstructure. It should be noted that exceeding 550°C or prolonging the holding time may cause graphitization, reducing strength and hardness.

4. Annealing to Eliminate White-Fracture Structure

During cooling, the surface and thin sections of a casting often develop a hard, brittle white-fracture structure, which has poor machinability and tends to flake. To eliminate this structure, annealing (or normalizing) must be used. The annealing process involves heating to 550–950°C, holding for 2–5 hours, followed by furnace cooling to 500–550°C, and then air cooling. During high-temperature holding, primary cementite and eutectic cementite decompose into graphite and austenite. During subsequent furnace cooling, secondary cementite and eutectic cementite also decompose, undergoing graphitization. This decomposition reduces hardness, thereby improving machinability.

Safety Procedures During Annealing

Annealing involves certain hazards, so strict adherence to safety procedures is required. Key safety points include:

1. Equipment Inspection

Before operation, carefully check the furnace body, doors, trolleys, wire rope pulleys, and blowers for normal function and for any risk factors such as collapse, fracture, or cracks. Any anomalies must be resolved before starting the furnace.

2. Fuel Preparation

When using an electric furnace, clean any oxide scale and metal near the resistance wires. When firing a coal furnace, check for explosives in coal. During shutdown, avoid excessive coal layer thickness to prevent gas explosions. Remove coal slag promptly without stockpiling.

3. Loading and Unloading

Before loading/unloading, inspect tracks for obstacles and ensure hooks and chains are reliable. Large castings or thin-walled components must be placed flat and stable. Leave proper spacing between items and do not exceed specified load height. Before removing from the furnace, clean refractory bricks and mortar on the furnace door and check the trolley mechanism.

4. Removal and Transport

During removal and transport, unrelated personnel must stay away from either side of the trolley to prevent injury from falling sand boxes or workpieces. Do not rest or place objects near the furnace. For workpieces above 400°C, do not lift with chains or wire ropes unless insulated, to avoid breakage after annealing. Follow crane and hook operation safety protocols.

5. Fuel Ignition

For gas furnaces, follow ignition sequence: blow out residual gases with compressed air, close the air valve, ignite the torch, slightly open the gas nozzle, adjust air and gas flow for full combustion. Shut-off sequence is reversed—never invert order. For oil-fired furnaces, close the air gate first, ignite the torch, slightly open the fuel, then adjust air and fuel for full combustion. Powder fuel furnaces must not be operated with defective blowers or cracked pipelines.

6. Equipment Maintenance

When repairing electric furnaces, switch off the main power and hang a “Maintenance in Progress – Do Not Switch On” sign, or ensure supervision.

Aging Treatment of Castings

During the cooling process of castings, uneven shrinkage occurs due to different cooling rates in various areas, resulting in internal stresses. These internal stresses can be relieved through deformation of the casting, but this process is generally slow. Therefore, castings require aging treatment after formation, especially for large, complex, or high-precision castings (such as bed frames and machine frames).

1. Natural Aging

Natural aging involves leaving the formed castings at room temperature for an extended period to eliminate internal stresses. This method takes a long time, usually six months or even more than a year. The advantage of natural aging is low cost, while its disadvantage is the long cycle and low efficiency.

2. Artificial Aging

To shorten the aging period, artificial aging (also called stress-relief annealing) is commonly used to eliminate internal stresses in castings. The principle of artificial aging is to reheat the casting to 530–620 °C, hold it at that temperature for a long period (2–6 hours), using plastic deformation to reduce stress, and then slowly cool it in the furnace to below 200 °C before removing it for air cooling. After stress-relief annealing, more than 90% of the internal stresses can be eliminated.

The higher the aging temperature, the more effectively the residual stress in the casting is relieved, and the better the dimensional stability. However, as the aging temperature increases, the mechanical properties of the casting after aging may decrease. Therefore, it is important to reasonably determine the heating temperature for stress-relief annealing of castings. The holding time is generally calculated based on 25 mm of casting thickness per hour for full heat penetration. The heating rate is usually controlled below 80 °C/h, and for complex parts below 20 °C/h. The cooling rate should be controlled below 30 °C/h, followed by air cooling after 200 °C.

After the casting surface is machined, the original stress field is disrupted, which may lead to a redistribution of stresses in the casting. Therefore, stress-relief annealing is recommended after rough machining. For precision parts with particularly high requirements, two rounds of stress-relief annealing can be performed after casting formation and rough machining.

Conclusion

Annealing plays a crucial role in the production of cast steel components. Through methods such as full annealing, homogenization annealing, stress-relief annealing, and annealing to eliminate white-fracture structures, the performance of castings can be effectively improved, making them better suited for subsequent machining and service. Safety procedures during annealing and aging treatment methods are also critical, directly impacting the quality and efficiency of production. This article aims to help casting industry professionals better understand and apply annealing techniques to enhance the overall quality and performance of cast steel components.

Send your message to this supplier

Related Articles from the Supplier

Annealing Process of Cast Steel Components

- Sep 19, 2025

Forging and Annealing Processes of Copper Alloys

- Oct 30, 2024

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.forging-casting-stamping.com/annealing-process-of-cast-steel-components.html