A Guide to Non-Ferrous Alloy Casting

In the vast realm of modern industrial manufacturing, non-ferrous alloy casting plays a very important role. With its unique advantages and extensive applications, it provides solid support for the prosperity of numerous industries. Whether it is airplanes soaring in the sky or giant ships sailing in the deep sea; whether it is precision mechanical parts or various daily utensils, the applications of non-ferrous alloy casting are omnipresent. Now, let us delve into the mysteries of non-ferrous alloy casting and explore its significant role in industrial manufacturing.

Aluminum Alloy Casting: Lightweight & Strong

Among the many materials used in non-ferrous alloy casting, aluminum alloy stands out as an indispensable material in industrial manufacturing due to its unique properties and wide range of applications. It not only has the advantage of being lightweight but also possesses excellent mechanical properties and corrosion resistance. It is widely used in industries such as aviation, automotive, and chemical engineering. Next, we will explore the performance advantages of aluminum alloy and the characteristics of its casting process in detail.

1. Performance Advantages of Aluminum Alloy

Aluminum alloy distinguishes itself from other metal materials with its outstanding performance. Its density is relatively low, only about one-third of that of cast iron and cast steel. This means that under the same load-bearing conditions, using aluminum alloy castings can significantly reduce the weight of the structure. This characteristic has made it shine in the aviation industry. Many key parts of airplanes, such as the fuselage, wings, and engine components, extensively use aluminum alloy castings. This not only improves the fuel efficiency of the aircraft but also enhances its maneuverability and range. In the manufacturing of power machinery and transportation machinery, aluminum alloy castings also play an important role. For example, the engine block and cylinder head of automobiles, made of aluminum alloy, not only reduce the weight of the car but also improve fuel economy and reduce exhaust emissions, contributing to environmentally friendly travel.

In addition to its lightweight advantage, aluminum alloy also has good surface luster and excellent corrosion resistance in the atmosphere and fresh water. This makes aluminum alloy castings widely used in the manufacturing of civilian utensils, such as tableware, kitchenware, and decorative items. Pure aluminum also has good corrosion resistance in oxidizing acid media such as nitric acid and acetic acid. Therefore, in the chemical industry, aluminum castings can be used to manufacture specific reaction vessels and pipes. Moreover, the thermal conductivity of pure aluminum and aluminum alloy is very good. In chemical production, heat exchangers need good thermal conductivity to ensure rapid heat transfer and uniform distribution. Aluminum alloy is undoubtedly an ideal choice. In the field of power machinery, components such as the cylinder head and piston of internal combustion engines require good thermal conductivity to dissipate heat in time and prevent the engine from overheating. Aluminum alloy can also meet this requirement.

2. Casting Performance of Aluminum Alloy

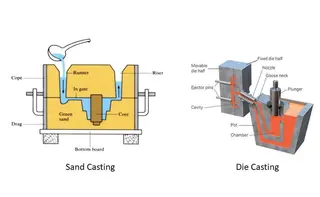

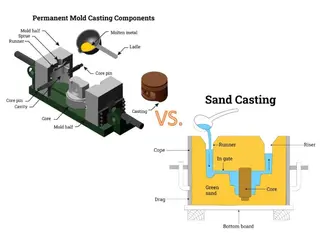

The casting performance of aluminum alloy is also unparalleled. Its melting point is relatively low, with pure aluminum having a melting point of 660.23°C and the pouring temperature of aluminum alloy generally around 730°C to 750°C. This allows aluminum alloy to be widely used in casting methods such as metal mold casting and pressure casting. Metal mold casting can improve the internal quality, dimensional accuracy, and surface finish of castings while also increasing production efficiency. Pressure casting can rapidly fill the mold with molten metal under high pressure, further improving the quality and surface quality of the casting.

Aluminum alloy has a large solidification latent heat. Under the same weight conditions, the solidification process of aluminum liquid takes much longer than that of cast steel and cast iron, so its fluidity is good. This characteristic makes aluminum alloy particularly suitable for casting thin-walled and complex-structured castings, meeting the high requirements of modern industry for the manufacturing of complex parts.

Casting Copper Alloy: Corrosion & Wear Resistant

In many fields of industrial manufacturing, copper alloy has become the ideal material for manufacturing high-precision and high-performance parts due to its excellent corrosion and wear resistance. Whether it is corrosion-resistant components in marine engineering or high-load parts in mechanical manufacturing, copper alloy can provide reliable solutions. Next, we will gain an in-depth understanding of the performance advantages of casting copper alloy and its wide applications in industry.

1. Performance Advantages of Copper Alloy Casting

Casting copper alloy also plays an indispensable role on the industrial stage. Copper-based alloys have excellent corrosion resistance and perform well in fresh water, seawater, and certain chemical solutions, so they are widely used in shipbuilding and chemical industries. The propellers and hull components of ships need to withstand the long-term erosion of seawater. Copper alloy castings can effectively resist seawater corrosion and extend the service life of ships. In the chemical industry, copper alloys can be used to manufacture various corrosion-resistant pipes, containers, and reaction equipment to ensure the safety and stability of chemical production processes.

In addition to corrosion resistance, casting copper alloy also has good thermal conductivity and wear resistance. This makes copper alloy castings often used to manufacture sliding bearings and bushings that bear heavy loads and high-speed rotating shafts in various machines. During mechanical operation, these parts need to withstand great pressure and friction. The wear resistance of copper alloy can ensure that they maintain good performance during long-term operation, reducing wear and replacement frequency.

2. Classification and Casting Methods of Copper Alloy

Casting copper alloy is divided into two main categories: brass and bronze. Brass is a copper alloy with zinc as the main alloying element. Depending on the other alloying elements added, it can be further divided into manganese brass, aluminum brass, silicon brass, lead brass, etc. Bronze is a copper alloy that does not use zinc as the main alloying element. Common types include tin bronze, aluminum bronze, lead bronze, beryllium bronze, etc. According to national standards, there are 9 types and 29 grades of casting copper alloys, providing a rich and diverse range of choices for different industrial applications.

In terms of casting methods, in addition to traditional sand casting, copper alloys also widely use various special casting methods such as metal mold casting, centrifugal casting, low-pressure casting, and graphite mold casting. Metal mold casting can accelerate the solidification of the alloy, which is important for improving casting quality and reducing casting defects. It can refine grains, especially for aluminum bronze and manganese brass, reduce porosity, and improve the mechanical properties and air tightness of the alloy, which is particularly important for tin bronze. In copper alloys with high lead content, such as lead bronze, metal mold casting (and water-cooled metal mold casting) can effectively prevent the segregation of copper components. Since there are many cylindrical parts (such as bearings and bushings) in copper alloy castings, centrifugal casting is widely used. Centrifugal casting allows the molten metal to solidify under the action of centrifugal force in a rotating mold, resulting in castings with dense structure and good mechanical properties. In addition, large copper castings (such as large ship propellers) can also use low-pressure casting. Low-pressure casting allows the molten metal to rise and fill the mold under low pressure, which can increase the density of the alloy, reduce the inclusions generated during the casting process, and thus improve the quality and performance of the casting.

Other Common Non-Ferrous Alloy Casting

In addition to aluminum and copper alloys, many other non-ferrous alloys play important roles in the casting field. These alloys each have their own characteristics, from lightweight and high-strength magnesium alloys to corrosion-resistant titanium alloys, and to zinc alloys with excellent casting properties. They are indispensable in various fields such as aviation, chemical engineering, and automotive. Next, we will explore the unique properties of these non-ferrous alloys and the characteristics of their casting processes one by one.

1. Magnesium Alloy Casting

Magnesium and titanium alloys are highly favored by the aviation industry for their high specific strength. Magnesium alloy is characterized by its light weight and high strength, which can significantly reduce the weight of components while ensuring strength. In the aviation field, reducing structural weight is of great importance, and magnesium alloy is widely used in components such as aircraft seat frames and luggage racks. However, the casting performance of magnesium alloy is relatively poor, especially prone to hot cracking. Therefore, most magnesium alloy castings still use sand casting. Only castings with simple shapes can use metal mold casting. Pressure casting is rarely used in magnesium alloy casting, mainly because magnesium alloy is prone to oxidation and combustion at high temperatures, and the requirements for casting processes are extremely high.

2. Titanium Alloy Casting

Titanium alloy not only has high specific strength but also has strong corrosion resistance to a variety of corrosive media. Therefore, in petrochemical equipment, when manufacturing castings subjected to corrosive effects, titanium alloy is an ideal choice. Titanium alloy is extremely chemically active. During the casting process, titanium liquid will interact with most mold materials (including various sands and steel), causing the casting to be contaminated. Therefore, titanium alloy can only be cast with special mold materials (such as thorium oxide or graphite). The melting process has a crucial impact on the performance and quality of titanium alloy castings. Since titanium alloy is prone to porosity and inclusions during the melting process, it is necessary to strictly control the melting process to ensure the quality of the castings.

3. Zinc Alloy Casting

Zinc alloy is widely used in the manufacture of thin-walled and complex-structured castings due to its high strength and excellent casting properties. For example, in the automotive industry, many automotive parts, such as wheels and engine supports, are made of zinc alloy castings. They not only meet the strength requirements but also achieve complex designs and lightweight goals. Zinc alloy has good casting properties and strong mold filling ability, and it does not produce hot cracking. It is particularly suitable for metal mold and pressure casting. In mass production, pressure casting is commonly used to produce thin-walled and complex-structured zinc alloy castings. Pressure casting can rapidly fill the mold with molten metal under high pressure, resulting in castings with precise dimensions and smooth surfaces, greatly improving production efficiency and product quality.

Conclusion

Non-ferrous alloy casting plays a vital role in industrial manufacturing. From the lightweight and high thermal conductivity of aluminum alloy, to the corrosion and wear resistance of copper alloy, and to the unique advantages of magnesium, titanium, and zinc alloys, these materials have a wide range of applications in many fields such as aviation, automotive, chemical, and mechanical engineering. With the continuous progress of science and technology, non-ferrous alloy casting technology is also constantly innovating and developing. In the future, it is expected to achieve greater breakthroughs in the research and development of high-performance materials, the application of green casting technology, and intelligent casting. Non-ferrous alloy casting will continue to make important contributions to human technological progress and economic development, and promote industrial manufacturing to develop in a more efficient, environmentally friendly, and intelligent direction.

Send your message to this supplier

Related Articles from the Supplier

A Guide to Non-Ferrous Alloy Casting

- Jun 27, 2025

A Comprehensive Guide to Aluminum Forgings

- Jul 25, 2024

A Comparison of Die Casting and Sand Casting

- Apr 30, 2025

What is a Cold Forged Stainless Steel Wing Nut?

- Sep 06, 2024

Related Articles from China Manufacturers

A Guide to The Types of Ball Valves

- Dec 10, 2025

A Guide to the Selection and Use of Valve

- Nov 08, 2024

A Guide to Media Selection for Multi-Media Filters

- Jul 25, 2024

A Guide to Steel Selection in Pressure Vessel Design

- Aug 08, 2025

Related Products Mentioned in the Article

Supplier Website

Source: https://www.forging-casting-stamping.com/a-guide-to-non-ferrous-alloy-casting.html