Basic Knowledge of Brass (Part Two)

Special brass

The multiple alloys which are formed by adding other alloying elements to ordinary brass are called special brass. The common added alloying elements are lead, tin, aluminum, etc., and the multiple alloys can be called lead brass, tin brass and aluminum brass. The purpose of adding alloying elements is to improve tensile strength and manufacturability.

Brass alloy can be represented by H and the element symbol of the main added element(except zinc) and mass fraction of copper and mass fraction of the main added element and mass fraction of other elements. For example, HPb59-1 means that mass fraction of copper is 59%, the main added element lead 1%, and the rest of mass fraction is zinc.

Classifications

In order to improve corrosion resistance, strength, hardness and machinability of brass, a small amount of tin, aluminum, manganese, iron, silicon, nickel, lead and other elements is often added to copper zinc alloy, forming ternary alloy, quaternary alloy and even quinary alloy. They are called complex brass and also known as special brass. The small amount of added alloying elements is generally 1% to 2%, sometimes 3% to 4% and hardly 5% to 6%.

Zinc equivalent coefficient

The complex brass structure can be calculated according to the zinc equivalent coefficient of the added element in the brass. A small amount of other alloying elements is added to copper-zinc alloy, and the α or α plus β phase region in the Cu-Zn phase diagram usually shifts left or right only. Therefore, the structure of special brass is usually equivalent to the zinc structure which is increased or decreased in the ordinary brass. For example, the structure of 1% silicon added to Cu-Zn alloy is equivalent to the alloy structure which is added 10% zinc. Therefore, the zinc equivalent of silicon is 10.

Performance

The α and β phases in the special brass are multiple complex solid solutions, which have a greater strengthening effect. However, the α and β phases in ordinary brass are simple Cu-Zn solid solutions with less strengthening effect. Properties of multiple solid solutions and simple binary solid solutions are not the same, although their zinc equivalent is almost the same. Therefore, a small amount of alloying elements with multiple strengthening is a way of improving performance of alloys.

Lead brass

Lead does not actually dissolve in brass and will be in the state of free particles distributed in the grain boundary. Lead brass can be classified into α lead brass and α plus β lead brass based on its structure. α lead brass can only be processed by cold deformation or hot extrusion, because lead has the great harmful effect and its high temperature plasticity is very low. α plus β lead brass has good ductility at high temperatures, and it can be processed by the forging process.

The multiple alloys which are formed by adding other alloying elements to ordinary brass are called special brass. The common added alloying elements are lead, tin, aluminum, etc., and the multiple alloys can be called lead brass, tin brass and aluminum brass. The purpose of adding alloying elements is to improve tensile strength and manufacturability.

Brass alloy can be represented by H and the element symbol of the main added element(except zinc) and mass fraction of copper and mass fraction of the main added element and mass fraction of other elements. For example, HPb59-1 means that mass fraction of copper is 59%, the main added element lead 1%, and the rest of mass fraction is zinc.

Classifications

In order to improve corrosion resistance, strength, hardness and machinability of brass, a small amount of tin, aluminum, manganese, iron, silicon, nickel, lead and other elements is often added to copper zinc alloy, forming ternary alloy, quaternary alloy and even quinary alloy. They are called complex brass and also known as special brass. The small amount of added alloying elements is generally 1% to 2%, sometimes 3% to 4% and hardly 5% to 6%.

Zinc equivalent coefficient

The complex brass structure can be calculated according to the zinc equivalent coefficient of the added element in the brass. A small amount of other alloying elements is added to copper-zinc alloy, and the α or α plus β phase region in the Cu-Zn phase diagram usually shifts left or right only. Therefore, the structure of special brass is usually equivalent to the zinc structure which is increased or decreased in the ordinary brass. For example, the structure of 1% silicon added to Cu-Zn alloy is equivalent to the alloy structure which is added 10% zinc. Therefore, the zinc equivalent of silicon is 10.

Performance

The α and β phases in the special brass are multiple complex solid solutions, which have a greater strengthening effect. However, the α and β phases in ordinary brass are simple Cu-Zn solid solutions with less strengthening effect. Properties of multiple solid solutions and simple binary solid solutions are not the same, although their zinc equivalent is almost the same. Therefore, a small amount of alloying elements with multiple strengthening is a way of improving performance of alloys.

Lead brass

Lead does not actually dissolve in brass and will be in the state of free particles distributed in the grain boundary. Lead brass can be classified into α lead brass and α plus β lead brass based on its structure. α lead brass can only be processed by cold deformation or hot extrusion, because lead has the great harmful effect and its high temperature plasticity is very low. α plus β lead brass has good ductility at high temperatures, and it can be processed by the forging process.

Send your message to this supplier

Related Articles from the Supplier

Basic Knowledge of Brass (Part Two)

- Nov 24, 2017

Basic Knowledge of Brass (Part One)

- Nov 10, 2017

Basic Knowledge of Brass (Part Three)

- Jan 30, 2018

Related Articles from China Manufacturers

Basic Knowledge of Flanged Butterfly Valve

- Apr 25, 2017

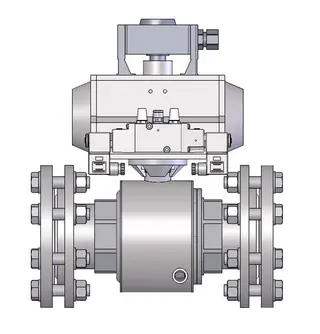

Basic Knowledge of Pneumatic Ball Control Valves

- May 15, 2024

Basic Knowledge of Bag Fabrics

- Mar 03, 2016

Basic knowledge of ferritic stainless steel forging

- Mar 06, 2019

Basic Knowledge of Safety Valves (Part One)

- Sep 08, 2017

Basic Knowledge of Safety Valves (Part Two)

- Sep 22, 2017

Basic Knowledge and Working Principle of Gate Valves

- Oct 27, 2021

Basic Knowledge of Metal Parts in Manufacture

- Sep 13, 2014

Related Products Mentioned in the Article

Supplier Website

Source: https://www.china-die-casting.com/basic-knowledge-of-brass-part-two.html

-150x145.webp)