Basic Knowledge of Brass (Part One)

Brass which is made of copper and zinc is called ordinary brass. A variety of alloys which is made of two or more elements is called special brass. For example, copper alloys are made of lead, tin, manganese, nickel, iron and silicon.

Brass has strong wear resistance. Special brass has high strength, high hardness, strong chemical resistance as well as outstanding mechanical properties for cutting processes. Seamless copper pipes which are made of brass have advantages of being soft and having strong wear resistance. Brass which contains sixty two to sixty eight percent of copper has strong plasticity, and it is used for manufacturing pressure equipment. Brass alloys containing zinc lower than 36% are made of solid solutions, and they have good cold processing properties. For example, brass that contains thirty percent of zinc is usually used for making shell cases, which is also known as cartridge brass. Brass alloy which contains 36 to 42 percent of zinc is made of solid solutions.

Aluminum, nickel, manganese, tin, silicon, lead and other elements are often added to brass in order to improve the performance of ordinary brass. Aluminum can improve strength, hardness and corrosion resistance of brass, but make plasticity of brass poor. This kind of brass is applicable to condenser pipes of seagoing vessels and other parts which are corrosion resistant. Tin can improve strength of brass and brass's corrosion resistance to seawater, and this kind of brass is called admiralty brass. It is applied to thermal equipment and propellers for ships. Lead can improve cutting performance of brass, and this kind of brass is often used for making clocks and watches' components. Brass castings are often used to produce valves and pipe fittings.

Ordinary brass

Ordinary brass is made of copper and zinc alloy. When the zinc content is less than 39%, zinc can be dissolved in copper, forming a single phase α, which is known as single phase brass. It has good plasticity and is suitable for hot and cold pressure processing. When the zinc content is greater than 39%, there are single phase α and copper-based β solid solutions, which is called two phase brass. The β solid solution makes plasticity of brass poor, but improves tensile strength. This kind of brass is only suitable for hot press working.

If the mass fraction of zinc is continually increased, the tensile strength will decrease, resulting in no use value. Brass can be represented by H, and the number represents the mass fraction of copper. For example, H68 means that brass contains 68 percent of copper content and 32 percent of zinc content. If it is casting brass, we will put Z before the code, for example, ZH62. Zcuzn38 means that casting brass contains 38 percent of zinc content and the remaining 62 percent of copper content.

H90 and H80 belong to single-phase brass, and they are golden yellow. H68 and H59 belong to two-phase brass, and they are widely used for structural parts of electrical appliances such as bolts, nuts, washers, springs, etc. Generally, single-phase brass is used for cold deformation processing, and two-phase brass is used for hot deformation processing.

Brass has strong wear resistance. Special brass has high strength, high hardness, strong chemical resistance as well as outstanding mechanical properties for cutting processes. Seamless copper pipes which are made of brass have advantages of being soft and having strong wear resistance. Brass which contains sixty two to sixty eight percent of copper has strong plasticity, and it is used for manufacturing pressure equipment. Brass alloys containing zinc lower than 36% are made of solid solutions, and they have good cold processing properties. For example, brass that contains thirty percent of zinc is usually used for making shell cases, which is also known as cartridge brass. Brass alloy which contains 36 to 42 percent of zinc is made of solid solutions.

Aluminum, nickel, manganese, tin, silicon, lead and other elements are often added to brass in order to improve the performance of ordinary brass. Aluminum can improve strength, hardness and corrosion resistance of brass, but make plasticity of brass poor. This kind of brass is applicable to condenser pipes of seagoing vessels and other parts which are corrosion resistant. Tin can improve strength of brass and brass's corrosion resistance to seawater, and this kind of brass is called admiralty brass. It is applied to thermal equipment and propellers for ships. Lead can improve cutting performance of brass, and this kind of brass is often used for making clocks and watches' components. Brass castings are often used to produce valves and pipe fittings.

Ordinary brass

Ordinary brass is made of copper and zinc alloy. When the zinc content is less than 39%, zinc can be dissolved in copper, forming a single phase α, which is known as single phase brass. It has good plasticity and is suitable for hot and cold pressure processing. When the zinc content is greater than 39%, there are single phase α and copper-based β solid solutions, which is called two phase brass. The β solid solution makes plasticity of brass poor, but improves tensile strength. This kind of brass is only suitable for hot press working.

If the mass fraction of zinc is continually increased, the tensile strength will decrease, resulting in no use value. Brass can be represented by H, and the number represents the mass fraction of copper. For example, H68 means that brass contains 68 percent of copper content and 32 percent of zinc content. If it is casting brass, we will put Z before the code, for example, ZH62. Zcuzn38 means that casting brass contains 38 percent of zinc content and the remaining 62 percent of copper content.

H90 and H80 belong to single-phase brass, and they are golden yellow. H68 and H59 belong to two-phase brass, and they are widely used for structural parts of electrical appliances such as bolts, nuts, washers, springs, etc. Generally, single-phase brass is used for cold deformation processing, and two-phase brass is used for hot deformation processing.

Send your message to this supplier

Related Articles from the Supplier

Basic Knowledge of Brass (Part One)

- Nov 10, 2017

Basic Knowledge of Brass (Part Two)

- Nov 24, 2017

Basic Knowledge of Brass (Part Three)

- Jan 30, 2018

Related Articles from China Manufacturers

Basic Knowledge of Flanged Butterfly Valve

- Apr 25, 2017

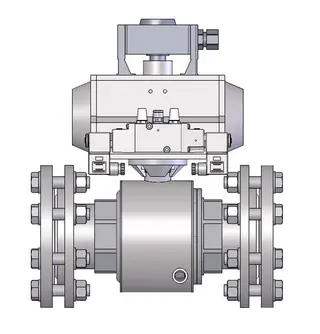

Basic Knowledge of Pneumatic Ball Control Valves

- May 15, 2024

Basic Knowledge of Bag Fabrics

- Mar 03, 2016

Basic knowledge of ferritic stainless steel forging

- Mar 06, 2019

Basic Knowledge of Safety Valves (Part One)

- Sep 08, 2017

Basic Knowledge of Safety Valves (Part Two)

- Sep 22, 2017

Basic Knowledge and Working Principle of Gate Valves

- Oct 27, 2021

Basic Knowledge of Metal Parts in Manufacture

- Sep 13, 2014

Related Products Mentioned in the Article

Supplier Website

Source: https://www.china-die-casting.com/basic-knowledge-of-brass-part-one.html

-150x145.webp)