Top 5 Butterfly Valve Manufacturers from China

Introduction

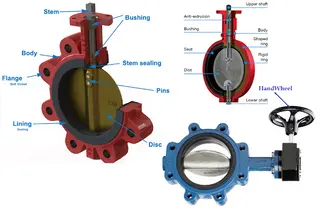

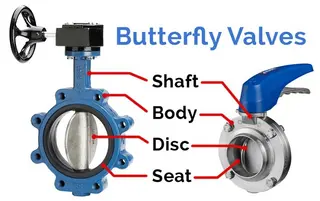

Butterfly valves are integral components in various industrial systems, known for their simple yet effective design. Widely used for controlling the flow of liquids, gases, and other media, butterfly valves are recognized for their ease of operation, compact design, and cost-effectiveness. These valves operate by rotating a disc within the valve body to either block or allow the flow of material.

As industries continue to expand globally, the demand for high-quality, reliable valves has skyrocketed, particularly from manufacturers in China. China, known for its advanced manufacturing capabilities and robust industrial infrastructure, has become a major player in the global valve market. This article will highlight the top 5 butterfly valve manufacturers from China, focusing on their manufacturing expertise, product offerings, and industry reputation.

What Are Butterfly Valves?

A butterfly valve consists of a disc, stem, and seal. The disc is connected to the stem and rotates to control fluid flow within a pipeline. The operating principle of a butterfly valve is simple and efficient: when the disc is parallel to the flow, the valve is open, and when it is turned 90 degrees, it closes the valve, preventing the flow.

Key Advantages of Butterfly Valves

1. Compact Design and Lightweight

Butterfly valves are smaller and lighter compared to other valve types, making them easy to install, maintain, and replace.

2. Quick and Easy Operation

A simple 90-degree turn is sufficient to fully open or close the valve.

3. Cost-Effective Solution

Butterfly valves are generally more affordable than other types of valves, making them ideal for cost-conscious projects.

4. Good Flow Control

Despite their simple construction, butterfly valves offer excellent control over the flow of fluid.

5. Low Pressure Drop

Butterfly valves are efficient in allowing fluid flow with minimal pressure loss.

Applications of Butterfly Valves

Butterfly valves are used across a broad range of industries, including:

Oil and Gas Industry

Butterfly valves are used for controlling the flow of crude oil, natural gas, and refined products.

Chemical Industry

These valves control the flow of various chemicals, gases, and liquids in chemical plants.

Water and Wastewater Treatment

Butterfly valves play a crucial role in water treatment systems, regulating the flow of water and sewage.

HVAC Systems

Used in heating, ventilation, and air conditioning systems to control airflow.

Fire Protection Systems

Butterfly valves are essential in fire suppression systems to control water flow.

How to Properly Install a Butterfly Valve

1. Align the Connecting Pipe Flanges

Ensure the pipe flanges are correctly aligned to avoid putting stress on the valve body.

2. Insert the Valve

Place the valve between the flanges with proper separation to avoid contact with the flange surfaces.

3. Check Movement

Before fully tightening the bolts, check if the valve can open and close smoothly.

4. Tighten the Bolts

Use an even sequence to tighten the bolts uniformly for proper sealing.

5. Final Test

Open and close the valve to verify the actuator’s travel stops and correct alignment.

Actuation Methods of Butterfly Valves

The actuation of butterfly valves is a critical factor in enhancing their performance. By using an actuator, butterfly valves can quickly open or close, providing efficient flow regulation. Various actuator types available for butterfly valves include:

1. Manual Valve Operation

Operated manually, ideal for small or infrequently used systems.

2. Electric Valve Actuator

Powered by electricity, offering precise control and remote operation.

3. Pneumatic Valve Actuator

Uses compressed air for rapid opening and closing.

4. Hydraulic Valve Actuator

Uses fluid pressure to control valve movement, suitable for high-force applications.

Top 5 Butterfly Valve Manufacturers from China

1. Xiamen Landee Valve Manufacturing Co., Ltd.

Founded in 1994, Xiamen Landee Valve Manufacturing Co., Ltd. has become a leading player in China’s valve manufacturing industry. Known for producing a wide range of valves, including butterfly valves, Landee Valve has earned a solid reputation for quality and innovation. The company manufactures valves in a variety of materials such as stainless steel, carbon steel, and alloy steel, making them suitable for different industrial applications.

Landee’s butterfly valves are particularly popular in the petrochemical, water treatment, and energy sectors. They offer products that comply with both domestic and international standards, including ISO, API, ANSI, BS, JIS, EN, and ASME. Their valves are designed for high performance and reliability, offering excellent flow control in various operating conditions.

2. DERVOS Valve Co., Ltd.

DERVOS Valve Co., Ltd., established in 2008, is a prominent Chinese manufacturer specializing in high-quality valves for industrial applications. Headquartered in Xiamen with production facilities in Zhejiang, DERVOS focuses on providing solutions for challenging applications, including high-pressure, high-temperature, and corrosive environments.

DERVOS offers a broad range of butterfly valves that are suitable for industries like oil and gas, power generation, and chemical processing. The company’s commitment to innovation is reflected in its advanced manufacturing processes, ensuring the production of durable and reliable valves. DERVOS’s valves meet international standards, providing their clients with peace of mind when operating in demanding environments.

3. Zhejiang VERVO Valve Co., Ltd.

Zhejiang VERVO Valve Co., Ltd. is another prominent manufacturer with a strong reputation for producing high-quality industrial valves. The company operates a state-of-the-art facility spread over 15,000 square meters, equipped with the latest manufacturing technologies. VERVO’s product portfolio includes trunnion ball valves, pressure-sealed gate valves, cryogenic globe valves, and, of course, butterfly valves.

VERVO’s butterfly valves are designed for a variety of industrial applications, including oil and gas, power generation, and water treatment. The company holds several international certifications, including API, ASME, DIN, and ISO, ensuring that its products meet the highest safety and performance standards. VERVO’s commitment to quality and innovation has made it a trusted name in the valve manufacturing industry.

4. Baltic Valve Co., Ltd.

With over 15 years of experience in the valve manufacturing industry, Baltic Valve Co., Ltd. has established itself as a leading supplier of high-performance valves. Baltic’s butterfly valves are widely used in industries such as oil and gas, chemical processing, and water treatment. Known for their durable construction and precision engineering, Baltic valves are designed to meet the most demanding applications.

The company’s stringent quality control processes ensure that each valve is manufactured to the highest standards. Baltic Valve’s products are rigorously tested for reliability, performance, and durability, making them a trusted choice for global customers. The company also offers tailored solutions to meet the specific needs of clients, further cementing its reputation as a reliable and customer-centric manufacturer.

5. Bosseal Valve (Suzhou) Co., Ltd.

Bosseal Valve (Suzhou) Co., Ltd. is a global leader in valve manufacturing, known for producing high-quality valves for a variety of industrial applications. The company’s range includes ball valves, gate valves, globe valves, check valves, butterfly valves, and plug valves. Bosseal’s butterfly valves are designed for use in industries like oil and gas, chemical processing, and water treatment.

Bosseal’s manufacturing facility is equipped with advanced forging and machining technologies, allowing the company to produce valves that offer superior performance and durability. The company is committed to meeting international standards, including API, ASME, ISO, DIN, BS, and EN. Bosseal’s focus on quality, combined with its innovative manufacturing processes, ensures that its products perform reliably even in the most demanding conditions.

Conclusion

China has become a global leader in the valve manufacturing industry, with companies like Xiamen Landee Valve Manufacturing Co., Ltd., DERVOS Valve Co., Ltd., Zhejiang VERVO Valve Co., Ltd., Baltic Valve Co., Ltd., and Bosseal Valve (Suzhou) Co., Ltd. setting the standard for high-quality butterfly valves. These manufacturers offer a wide range of valves that meet the needs of various industries, from oil and gas to water treatment and power generation.

With their commitment to quality, innovation, and customer satisfaction, these Chinese valve manufacturers are well-positioned to meet the growing demand for reliable, cost-effective valve solutions worldwide. Whether you're looking for a valve for a new project or seeking a reliable supplier for replacement parts, these companies represent the best in the business.

Next: How to Identify a Reliable Chinese Swimwear Manufacturer?

Previous: How to Identify a Reliable Chinese Flange Supplier?