Strategies for Choosing a Reliable Gate Valve Supplier from China

On this page

China's Position as a Global Valve Manufacturer

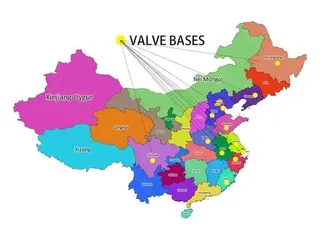

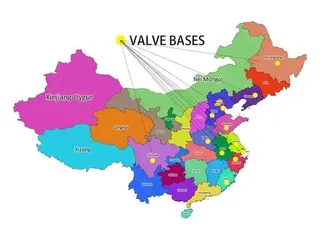

As a global manufacturing center, China can produce products for various industries on a large scale and efficiently. Valves made in China have become the preferred choice for many foreign importers due to their high cost-effectiveness and quality. Currently, China's valve production bases are mainly concentrated in Zhejiang, Jiangsu, Shandong, and other regions. These regions supply high-quality valves that meet international standards to the global market, supported by a complete industrial chain, extensive production experience, and professional technical expertise.

Choosing a reliable valve factory is crucial for foreign importers. High-quality factories not only strictly adhere to international quality standards to ensure product consistency but also provide efficient delivery cycles and professional after-sales support. Additionally, these factories often possess advanced production equipment, professional R&D teams, and multiple international certifications (such as ISO, API, and CE) to meet various application requirements.

Choosing a reliable valve factory is crucial for foreign importers. High-quality factories not only strictly adhere to international quality standards to ensure product consistency but also provide efficient delivery cycles and professional after-sales support. Additionally, these factories often possess advanced production equipment, professional R&D teams, and multiple international certifications (such as ISO, API, and CE) to meet various application requirements.

Ensuring the Quality of Valves Produced in China Matches the Sample

How can you ensure that the quality of valves produced in China matches the samples? A common issue for foreign importers is that the quality of valves produced in China often does not match the samples. You can take the following measures to significantly reduce product quality discrepancies, ensure consistent supply, and strengthen the stability of the supply chain:

Choosing a Reliable Valve Supplier

Conduct background checks on Chinese valve suppliers through B2B websites, where you can review their certification information, product details, and customer feedback. If necessary, you can hire a professional third-party investigation company to conduct a background check on the supplier for more detailed and reliable information. Alternatively, you can visit the factory yourself or hire a third party to do so. On-site, you can observe the equipment status and workforce, verify whether production equipment, workshop management, and quality inspection processes meet standards, and assess the factory's capability to consistently produce high-quality valves.

Signing a Clear Valve Contract

The contract should clearly specify product specifications, technical standards, certifications, production cycles, delivery times, and quality inspection requirements, such as sealing and pressure testing. Finally, include breach of contract liability and compensation clauses to clarify the responsibilities and obligations of both parties, especially regarding delayed delivery, to protect the rights and interests of valve importers. It is advisable to require suppliers to confirm all process parameters before production.

Real-time Monitoring of the Production Process

Importers can monitor the entire production process by sending representatives or entrusting third-party inspection agencies to be stationed in the factory. This process includes inspecting raw materials, casting and forging quality, machining, heat treatment, assembly, pressure testing, non-destructive testing, surface treatment, anti-corrosion treatment, and packaging and labeling to promptly identify and correct any deviations.

Quality Inspection

Before shipment, arrange for a representative or a third-party quality inspection company to conduct a sampling inspection according to contract standards. Unqualified valves should be reworked or redone immediately to prevent them from being shipped.

Over more than ten years in procurement, I have built cooperative relationships with numerous valve manufacturers and gained extensive industry experience. I have found that certain valve suppliers consistently excel in product quality, technical expertise, and service, making them trustworthy, high-quality choices. Here are several suppliers I recommend:

Over more than ten years in procurement, I have built cooperative relationships with numerous valve manufacturers and gained extensive industry experience. I have found that certain valve suppliers consistently excel in product quality, technical expertise, and service, making them trustworthy, high-quality choices. Here are several suppliers I recommend:

Baltic Valve Co., Ltd.

Baltic Valve has accumulated extensive experience in valve manufacturing. Utilizing advanced technology and stringent production management, the company produces high-quality valves suitable for various industries. Baltic Valve is dedicated to continuously improving production efficiency and ensuring that customer orders are completed with high quality within the specified time. Baltic Valve has established an excellent reputation in the industry and has become a leading supplier in the valve sector.

Xiamen Landee Valve Manufacturing Co., Ltd.

Landee Valve is recognized for its efficient production process and stringent quality control. Landee Valve boasts modern production facilities and advanced manufacturing technology to ensure that every valve shipped meets international industry standards and specific customer requirements.

DERVOS VALVE CO., LTD

DERVOS VALVE specializes in the research and development (R&D) and production of high-performance valves. With an advanced technical team and state-of-the-art production equipment, the company ensures the quality and reliability of each valve. DERVOS VALVE strictly adheres to international quality management standards throughout the production process, ensuring that every step is subject to rigorous quality control—from raw material procurement to finished product delivery—and strives to meet the highest industry standards in every detail.

Zhejiang VERVO Valve Co., Ltd.

VERVO Valve has earned an excellent reputation for its high-quality valves. The company specializes in the research and development (R&D) and production of a variety of industrial valves, strictly adhering to international standards for production and quality control, and has established long-term cooperative relationships with many well-known companies. VERVO regards product quality and customer requirements as its top priorities and is committed to providing customers with the highest quality valves.

Bosseal Valve (Suzhou) Co., Ltd.

Bosseal Valve specializes in the design and manufacture of high-end valves. With its good R&D capabilities and exceptional engineering and technical team, the company enjoys deep trust from its customers.

These companies not only possess advanced production equipment and a comprehensive quality control system, but also hold several international certifications (such as ISO and API) and can provide high-quality valves to meet the diverse needs of various industries. The strong reputations and extensive experience of these companies make them excellent choices when selecting a valve supplier.

These companies not only possess advanced production equipment and a comprehensive quality control system, but also hold several international certifications (such as ISO and API) and can provide high-quality valves to meet the diverse needs of various industries. The strong reputations and extensive experience of these companies make them excellent choices when selecting a valve supplier.

Next: How to Find Reliable Control Valve Suppliers in China

Previous: How to Find Reliable Valve Suppliers Online?