Reliable Cam Lock Manufacturers in China: Advanced Security Solutions for Industry

Introduction

Across industries where security, durability, and operational efficiency are essential, cam locks stand out as an indispensable component. Whether installed in smart self-service terminals, communication servers, transportation equipment, vending machines, or industrial enclosures, cam locks play a critical role in safeguarding assets and ensuring reliable performance. As global industries accelerate toward automation, digitalization, and smart device integration, the demand for high-quality mechanical security solutions continues to grow.

With China being one of the world’s leading centers for hardware and precision manufacturing, international buyers increasingly look toward Chinese suppliers for dependable cam lock solutions. However, not all manufacturers adhere to the same standards—making the process of identifying a reliable, technologically advanced, and quality-focused supplier more important than ever.

Manufacturers today are evaluated not only on their production scale but also on their innovation capabilities, professional testing technologies, supply chain reliability, and adherence to international certifications. This comprehensive news report takes a deep dive into the cam lock industry, examining their structure and function while profiling several top Chinese manufacturers known for their world-class capabilities, powerful R&D systems, and strong global presence.

Understanding Cam Locks: Function, Structure, and Industry Demand

What Are Cam Locks?

A cam lock is a simple yet highly effective mechanical fastening device used to secure doors, cabinets, lockers, panels, and various equipment enclosures. The name “cam lock” comes from the cam—a small metal component that rotates when a key turns the cylinder, thereby locking or unlocking the device.

The fundamental operating principle is straightforward:

Insert the correct key into the lock cylinder.

The internal mechanism aligns, allowing the cylinder to rotate.

As the cylinder turns, it moves the cam to secure or release the locking point.

This basic yet reliable mechanism has made cam locks an essential component across a wide range of industries, from IT server cabinets to consumer appliances, public infrastructure, vending machines, and more.

Why Cam Locks Are Still in Demand in Modern Industries

Despite the rise of digital and biometric security technologies, cam locks remain widely adopted due to their unique advantages:

Cost-effectiveness: Ideal for large-scale deployments.

Durability: Withstand frequent use and harsh environments.

Ease of operation: Simple, quick access without complex electronics.

Versatility: Suitable for metal, plastic, and wooden panels.

Modularity: Cams, keys, and cylinders can be customized to specific applications.

Because they offer the perfect balance of affordability, reliability, and security, cam locks continue to be the preferred solution in many sectors.

Key Components of a Cam Lock

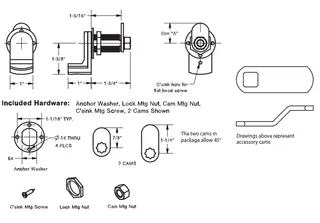

To understand how cam locks deliver reliable performance, it is helpful to unpack their core components:

1. Lock Cylinder

The cylinder houses the internal mechanical elements and receives the key. Inside, pins, discs, or tumblers align with the key cuts. A matching key allows smooth rotation, while any deviation prevents movement—ensuring the system’s security.

2. Formed Cam

The cam, attached to the rear of the cylinder, is the foundation of the locking action. As the cylinder rotates, the cam swings into a locking or unlocking position. Various cam shapes—flat, curved, hooked, offset—serve different applications.

3. Lock Housing

The housing secures the cylinder and cam in place and attaches to the mounting surface. High-strength materials ensure structural stability.

4. Key System

Keys vary in design—from flat keys to tubular, reversible, or digital combination interfaces. The matching key must correspond precisely to the cylinder’s configuration.

5. Spur Washer

A small but essential component, the spur washer holds the cam firmly to the cylinder so that the system remains stable even after thousands of operations.

Understanding these elements helps buyers evaluate the difference between basic cam locks and high-performance, long-life designs built for mission-critical environments.

How to Identify Reliable Cam Lock Manufacturers in China

China remains a global leader in the production of cam locks and precision hardware components. However, choosing the right manufacturer requires careful consideration of:

R&D capability

Production technology

Material quality and traceability

Testing methods and certifications

Innovation and patent portfolio

Customization capacity

After-sales service and technical support

International market experience

Below are three leading Chinese manufacturers whose strengths, credentials, and contributions significantly shape the cam lock industry.

1. Xiamen MAKE Security Technology Co., Ltd.

A Global Leader in Precision Metal & Plastic Structural Components

Xiamen MAKE Security Technology Co., Ltd. is widely recognized as one of China’s most innovative and technologically advanced manufacturers specializing in precision metal structural parts. Over the years, MAKE has developed a strong reputation in markets such as communication servers, intelligent self-service machines, personal computers, industrial equipment, and automotive systems.

Comprehensive Production Capability

MAKE operates a fully integrated production ecosystem covering:

Precision mold design

CNC machining

Precision die casting

Precision punching

Plastic injection molding

Automated assembly

Professional inspection and testing

With such a complete production chain, MAKE maintains strong control over quality, cost, and delivery schedules. Its current monthly output reaches 1.5 million lock units, positioning the company as a high-capacity, high-efficiency supplier for global orders.

Commitment to R&D and Technological Advancement

Innovation drives MAKE’s corporate philosophy. The company invests a significant percentage of annual revenue in R&D, resulting in:

389 patents

28 software copyrights

Multiple invention and international patents

These impressive achievements have earned MAKE several prestigious titles, including:

National Intellectual Property Advantage Enterprise

National High-Tech Enterprise

Fujian Enterprise Technology Center

Best Employer Award

Such recognition reflects MAKE’s substantial contributions to China’s precision hardware and smart device component sectors.

Future Strategy and Market Vision

MAKE plans to further expand its capabilities through:

Continuous investment in innovation

Enhanced customization capacity (ODM, OEM, JDM)

Stronger safety and precision performance

Sustainable manufacturing upgrades

With a forward-thinking approach, MAKE is set to maintain its leadership position in precision metal structural parts and advanced locking technologies for years to come.

2. Topper Cam Lock

One of China’s Most Established Cam Lock Innovators Since 1995

Founded in 1995, Topper Cam Lock has evolved into one of the country’s largest and most reputable cam lock manufacturers. With over 20 years of experience, the company is known for its robust R&D strength, large-scale production capability, and comprehensive catalog of household, commercial, and industrial lock products.

Technology-Driven Development

From the start, Topper has centered its growth strategy around continuous innovation. Its R&D team is dedicated to enhancing existing technologies and pioneering new locking solutions that meet the evolving needs of modern industries.

Extensive Portfolio of Locking Products

Topper provides a diverse array of cam locks, including:

Flat key cam locks

Pin tumbler cam locks

Tubular cam locks

Disc tumbler cam locks

Reversible key cam locks

Digital combination cam locks

Cylinder cam locks

Customized locking solutions

The wide variety ensures compatibility with numerous applications—from vending machines to office cabinets, from industrial panels to consumer products.

Nationwide Service & Global Market Presence

Topper operates technical service centers in over 70% of Chinese cities, providing customers with fast support, installation assistance, and technical consultation. As an OEM partner, the company has also helped manufacture locking products for multiple well-known brands.

Topper’s commitment to excellence is reflected in its certification under ISO 9001:2008. The company has consistently passed inspections by the Ministry of Public Security and other regulatory bodies.

With strong global distribution, Topper exports a large portion of its products and continues to expand its international influence.

3. Vending Machine Lock Manufacturer

A Specialized High-Security Lock Producer Since 2004

Established in 2004, Vending Machine Lock Manufacturer—well known for its MK LOCK brand—focuses exclusively on high-security locks for vending machines, ATMs, game machines, self-service equipment, and industrial smart terminals.

Deep Expertise in High-Security Locks

With more than 20 years of specialized experience, the company has accumulated:

30+ patents

Two international patents

Expertise in vending machine mechanisms, smart terminals, and financial equipment

Its products are widely used in:

Vending machines

ATM and banking devices

Public utility terminals

Ticketing and entertainment machines

Intelligent water and book vending systems

Electrical and industrial equipment

Large Facility and Technical Strength

Spanning 30,000 square meters, the company’s manufacturing campus includes:

Mold development center

Die-casting workshops

CNC center

Auto-lathing lines

Punching workshops

Key processing workshops

Final assembly and automated inspections

Warehousing and logistics

More than twenty senior engineers with decades of experience ensure the company maintains a leading technological advantage.

Strict Quality Assurance System

Quality is the company’s top priority. It holds:

ISO 9001:2015

ISO 14001:2004

Advanced testing equipment—such as salt spray testers, torsion testers, hardness meters, and life-span testing machines—guarantee product durability and reliability.

Remarkably, the company reinvests 50% of its profits back into R&D each year—an extraordinary commitment that keeps it ahead of competitors.

Strong International Presence

With exports to nearly 100 countries, the company enjoys long-term cooperation with more than 50 major enterprises. Its MK LOCK brand is known worldwide for:

High safety

Anti-theft strength

Long operating life

Precision engineering

Stable performance under harsh conditions

The Future of China's Cam Lock Industry

China’s cam lock industry is rapidly evolving, driven by:

Growing demand for secure smart terminals

Expansion of communication server infrastructure

Increased use of vending and automated retail machines

Industrial equipment upgrades

Adoption of new materials (stainless steel, high-performance plastics, zinc alloys, etc.)

Rising interest in integrated digital and mechanical security solutions

Manufacturers that prioritize R&D, automation, testing technology, and global certification compliance are expected to lead the next phase of development.

Key Future Trends Include:

More environmentally friendly manufacturing processes

Higher precision tolerances through CNC and die-casting automation

Wider adoption of modular lock systems

Integration of digital passwords and IoT capability

Increased export demand from Europe, North America, and emerging markets

As global industries continue to demand advanced locking systems for smart devices, China’s leading manufacturers will play an increasingly important role in shaping the market.

Conclusion

Cam locks remain essential components across numerous industries, providing security, ease of use, and long-term reliability. As businesses seek stronger, safer, and more efficient infrastructure, the importance of selecting a dependable manufacturer becomes increasingly significant.

Industry leaders such as:

Xiamen MAKE Security Technology Co., Ltd.

Topper Cam Lock

Vending Machine Lock Manufacturer

exemplify the highest standards of innovation, quality assurance, and large-scale manufacturing excellence in China. With strong R&D capabilities, integrated production systems, and global recognition, these companies offer world-class solutions for customers seeking secure and reliable cam lock products.

As China continues to advance technologically and expand globally, its cam lock industry is expected to grow even stronger—providing the world with high-performance mechanical security solutions for decades to come.

Next: How to Choose the Right Forging Supplier in China?

Previous: Guide to Choosing Reliable China Ball Valve Manufacturers