How to Choose the Right Chinese Cam Lock Manufacturer?

Introduction

In today's increasingly interconnected industrial world, small components often play a decisive role in ensuring safety, functionality, and long-term reliability. One such component is the cam lock. Although compact in size, cam locks are widely used across industries ranging from electronics and telecommunications to transportation, furniture, medical equipment, and self-service terminals.

As global manufacturers seek cost-effective, high-quality sourcing solutions, China has become one of the world's leading production centers for industrial locks, including cam locks. However, with thousands of suppliers offering similar products, choosing the right Chinese cam lock manufacturer is no simple task. Factors such as product quality, design capability, certification, production capacity, innovation, logistics, and after-sales service can significantly affect the performance of your products and the stability of your supply chain.

This article provides a comprehensive guide to understanding cam locks, distinguishing them from related hardware, and most importantly, selecting a reliable cam lock manufacturer in China. It also highlights leading manufacturers and explains what sets top-tier suppliers apart in an increasingly competitive market.

What Is a Cam Lock?

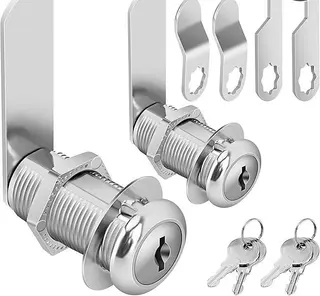

A cam lock is a compact mechanical fastener used to secure doors, drawers, cabinets, panels, and enclosures to a frame or housing. Its popularity lies in its simple construction, ease of installation, and dependable performance in low- to medium-security applications.

Structurally, a cam lock consists of two primary parts:

- The lock body (cylinder): This cylindrical housing fits into a pre-drilled hole in the panel or door.

- The cam (lever): Mounted on the rear of the cylinder, the cam rotates when the key is turned.

When the correct key is inserted and rotated, the cam turns behind the fixed frame or strike plate. In the locked position, the cam blocks movement, preventing the door or panel from opening. When unlocked, the cam aligns with the opening, allowing the door or panel to be accessed.

Cam locks are favored for their compact size, simple operation, and adaptability. They can be manufactured in various lengths, materials, and keying options, making them suitable for a wide range of applications, including:

- Electrical cabinets and control panels

- Server racks and communication enclosures

- Vending machines and self-service kiosks

- Furniture, filing cabinets, and lockers

- Medical cabinets and laboratory equipment

- Automotive compartments and industrial machinery

Because they are easy to install and replace, cam locks have become an industry standard for enclosures that require reliable fastening with basic access control.

Cam Lock vs. Cam Latch: Understanding the Difference

Although the terms “cam lock” and “cam latch” are often used interchangeably in everyday conversation, they refer to two distinct hardware components with different purposes. Understanding this difference is essential when selecting the right product and manufacturer.

Cam Lock: A Security Device

A cam lock is fundamentally a locking mechanism. It uses a key-operated system—typically based on pin tumblers, wafer tumblers, disc tumblers, or tubular designs—to restrict access. Only a matching key can rotate the cylinder and turn the cam.

Because of this, cam locks are used where access control and basic security are required. Common applications include:

- Electrical enclosures that must be protected from unauthorized access

- Server cabinets and network racks containing sensitive equipment

- Medical storage cabinets that require controlled entry

- Industrial control boxes in factories and infrastructure facilities

In these scenarios, the cam lock not only keeps a panel closed but also prevents unapproved users from opening it.

Cam Latch: A Fastening Device

A cam latch, often called a quarter-turn latch, is primarily a fastening mechanism rather than a security device. It does not typically use a keyed cylinder. Instead, it is operated by:

- A simple tool (slotted, square, or triangular drive)

- A hand knob or wing handle

Cam latches are designed to hold panels closed, often providing compression against a gasket to create a dust- or water-resistant seal. However, they do not prevent unauthorized access in the way a lock does.

They are commonly used in applications where frequent access is required and security is not critical, such as:

- Maintenance panels on machinery

- Access doors on HVAC systems

- Outdoor enclosures that rely more on sealing than security

Understanding this distinction helps buyers specify the correct product and ensures that manufacturers are evaluated based on the right technical requirements.

Why China Is a Global Hub for Cam Lock Manufacturing

Over the past two decades, China has emerged as a major global manufacturing center for hardware, including cam locks. Several factors contribute to this dominance:

Strong Manufacturing Infrastructure

China has well-developed industrial clusters dedicated to metalworking, precision machining, die casting, stamping, and plastic molding. These capabilities allow manufacturers to produce cam locks in large volumes with consistent quality.

Cost Efficiency

Through economies of scale, optimized supply chains, and advanced automation, Chinese manufacturers can offer competitive pricing without necessarily sacrificing quality. This makes sourcing from China attractive for both large corporations and small-to-medium enterprises.

Material Diversity

Chinese cam lock manufacturers commonly work with a wide range of materials, including:

- Zinc alloy

- Brass

- Stainless steel

- Aluminum

- Engineering plastics

This material flexibility allows buyers to select products based on corrosion resistance, strength, appearance, and cost.

OEM and ODM Capabilities

Many Chinese manufacturers provide OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services. This means they can produce cam locks according to a customer's design specifications or even develop new designs based on functional requirements.

How to Select the Right Cam Lock Manufacturer in China

Choosing the right supplier is not simply about finding the lowest price. A cam lock may be a small component, but poor quality can lead to equipment failures, safety issues, warranty claims, and reputational damage. Below are the key criteria buyers should evaluate.

1. Product Range and Technical Expertise

A reliable cam lock manufacturer should offer a broad portfolio of products to meet different application needs. Common categories include:

- Tubular cam locks: Known for compact design and higher pick resistance

- Flat key cam locks: Traditional design, widely used in cabinets and furniture

- Digital combination cam locks: Keyless access for modern applications

- Pin tumbler cam locks: Standard keyed systems with moderate security

Disc tumbler cam locks: Enhanced durability and smoother operation

A manufacturer with diverse offerings demonstrates technical capability and experience across industries. It also means the supplier can grow with your product line, rather than forcing you to change vendors when new requirements arise.

2. Material Quality and Manufacturing Processes

The performance and lifespan of a cam lock are closely tied to the materials used and the manufacturing processes employed. High-quality manufacturers typically use:

- Zinc alloy for cost-effective strength and corrosion resistance

- Brass for durability, smooth operation, and premium appearance

- Stainless steel for harsh environments requiring corrosion resistance

- High-performance plastics for lightweight and insulated applications

In addition, advanced manufacturing methods such as precision die casting, CNC machining, surface treatment, and automated assembly ensure dimensional accuracy and consistent quality.

When evaluating a manufacturer, buyers should inquire about:

- Material sourcing standards

- Surface finishing options (nickel plating, chrome plating, powder coating)

- Corrosion resistance and environmental testing

- Tolerance control and quality inspection procedures

3. Certifications and Quality Management Systems

International certifications are a strong indicator of a manufacturer's commitment to quality and compliance. One of the most important is ISO 9001, which demonstrates that the company has a standardized quality management system covering production, inspection, documentation, and continuous improvement.

A professional cam lock manufacturer should also maintain:

- Incoming material inspections

- In-process quality checks

- Final product testing

- Traceability and batch control

These systems reduce defect rates and ensure consistent performance across large production runs.

4. Research, Development, and Innovation

In today's competitive market, innovation is a key differentiator. Advanced cam lock manufacturers invest in:

- Product design and engineering teams

- Mold and tooling development

- New materials and surface treatments

- Smart lock and digital integration technologies

A strong R&D capability enables manufacturers to:

- Customize products for unique applications

- Improve durability and security features

- Develop next-generation solutions such as keyless or IoT-enabled locks

Buyers seeking long-term partnerships should prioritize suppliers with proven innovation records, patents, or proprietary technologies.

5. Production Capacity and Lead Time

For international buyers, supply reliability is as important as product quality. A suitable manufacturer must have:

- Sufficient production capacity to handle both small and large orders

- Flexible scheduling for urgent or seasonal demand

- Stable workforce and equipment

- Well-managed inventory and material procurement

Ask potential suppliers about their monthly or annual output, peak production capability, and average lead times. A factory that can scale with your business will reduce the risk of shortages or delayed shipments.

6. Logistics and Location Advantages

Logistics plays a crucial role in international sourcing. Manufacturers located near major ports and transportation hubs can offer faster and more cost-effective shipping.

Factories based in coastal cities such as Xiamen, Shenzhen, Ningbo, and Shanghai benefit from:

- Proximity to international seaports and airports

- Well-developed export infrastructure

- Experienced freight forwarding and customs handling

This logistical efficiency reduces transit times and helps ensure timely delivery to global customers.

7. Customer Service and Global Experience

Beyond manufacturing, a professional supplier must provide strong customer support, including:

- Technical consultation before production

- Sample development and testing

- Clear communication in English

- After-sales service and problem resolution

Manufacturers with extensive experience serving international clients are better equipped to understand overseas standards, documentation requirements, and business expectations.

Leading Cam Lock Manufacturers in China

China is home to numerous cam lock producers, but only a handful stand out for their scale, technology, and reputation. Two prominent examples are outlined below.

Xiamen MAKE Security Technology Co., Ltd.

Xiamen MAKE Security Technology Co., Ltd. is a high-tech enterprise specializing in the research, development, production, and sales of precision metal and plastic structural components. The company is widely recognized for its expertise in industrial locks and advanced manufacturing.

Core Capabilities

In the field of precision metal structural parts, MAKE's product range includes:

- Industrial locks

- Communication server components

- Hardware solutions for intelligent self-service terminals

- Components for personal computers, vehicles, and other industrial applications

These products are widely used in industries that require both mechanical reliability and precise manufacturing standards.

Innovation and Intellectual Property

Innovation lies at the core of MAKE's long-term strategy. The company invests a consistent percentage of its annual turnover into research and development. As a result, it has accumulated:

- 389 patents

- 28 software copyrights, including international and invention patents

This extensive intellectual property portfolio reflects MAKE's strong technical foundation and its ability to deliver proprietary solutions to customers.

Industry Recognition

Over the years, MAKE has earned multiple prestigious designations, including:

- “National Intellectual Property Advantage Enterprise”

- “National High-Tech Enterprise”

- “Fujian Enterprise Technology Center”

- “Best Employer”

These honors underscore its commitment to technology, quality, and corporate responsibility.

Topper Cam Locks: A One-Stop Cam Lock Solutions Partner

Topper Cam Locks is recognized as a leading cam lock manufacturer in China, specializing in the design and production of cam locks for global markets. With years of manufacturing experience, Topper provides a comprehensive range of locking solutions tailored to diverse industries.

Product Portfolio

Topper offers multiple categories of cam locks, including:

- Tubular cam locks

- Flat key cam locks

- Digital combination cam locks

- Pin tumbler cam locks

- Disc tumbler cam locks

These products are manufactured using high-quality materials such as zinc alloy, brass, and stainless steel to ensure durability, corrosion resistance, and consistent performance.

Strategic Location

Topper is located in Xiamen City, Fujian Province, China, a major coastal manufacturing hub with excellent port and airport infrastructure. This advantageous location allows efficient international logistics, enabling products to be delivered to customers worldwide in a timely manner.

Quality Management

Topper Cam Locks has achieved ISO 9001:2008 certification, demonstrating a robust quality management system. The company has established comprehensive quality control and assurance procedures across all stages of production and management. From raw material inspection to final product testing, every process is carefully monitored to ensure that customers receive products of consistently high quality.

Global Partnership Approach

Positioned as a one-stop cam lock solutions partner, Topper supports customers with:

Product selection and technical consultation

Custom design and OEM/ODM services

Stable production capacity

Reliable export logistics

This integrated service model makes Topper a preferred partner for clients seeking long-term collaboration rather than one-time transactions.

Common Applications of Cam Locks Across Industries

Understanding how cam locks are used across different industries can help buyers evaluate whether a manufacturer has the right experience.

- Electronics and Telecommunications: Securing server racks, control cabinets, and communication enclosures

- Vending and Self-Service Equipment: Locking doors on vending machines, ticketing kiosks, and payment terminals

- Furniture and Office Storage: Filing cabinets, lockers, drawers, and office furniture

- Medical and Laboratory Equipment: Protecting sensitive instruments and controlled-access storage

- Automotive and Transportation: Tool compartments, battery enclosures, and interior storage

- Industrial Machinery: Control panels, electrical boxes, and maintenance access doors

Manufacturers with cross-industry experience are better equipped to meet varying technical standards and environmental conditions.

Future Trends in the Cam Lock Industry

The cam lock market is evolving alongside broader trends in industrial hardware and security:

Digital and Keyless Solutions

As smart devices and IoT technologies expand, digital combination and electronic cam locks are gaining popularity. These solutions eliminate physical keys, improve access management, and integrate with centralized control systems.

Enhanced Security Features

Manufacturers are developing higher-security cam locks with advanced tumbler designs, anti-pick features, and tamper-resistant housings to address growing concerns about equipment protection.

Sustainability and Material Innovation

Environmental responsibility is influencing material selection and production methods. Recyclable materials, eco-friendly coatings, and energy-efficient manufacturing processes are becoming important differentiators.

Customization and Modular Design

Customers increasingly demand customized lock solutions that fit specific equipment designs. Modular cam lock systems allow manufacturers to quickly adapt components for different applications without redesigning entire products.

Conclusion

Selecting the right Chinese cam lock manufacturer is a strategic decision that goes far beyond pricing. A dependable supplier must combine product diversity, material quality, certifications, innovation, production capacity, logistics efficiency, and professional customer service.

By understanding the fundamentals of cam locks, distinguishing them from cam latches, and carefully evaluating manufacturers based on objective criteria, buyers can secure long-term partnerships that enhance product reliability and brand reputation.

Leading manufacturers such as Xiamen MAKE Security Technology Co., Ltd. and Topper Cam Locks exemplify the strengths of China's industrial lock sector—advanced technology, rigorous quality control, and global service capability.

In a world where security, efficiency, and precision are increasingly critical, choosing the right cam lock manufacturer is not merely a procurement decision—it is an investment in the durability, safety, and competitiveness of your products.

Previous: How to Choose a Reliable China Seamless Steel Pipe Manufacturer