Bolted Bonnet Gate Valve, API 602, ASTM A105, 800 LB, SW End

Key Specifications / Features

Detail Information

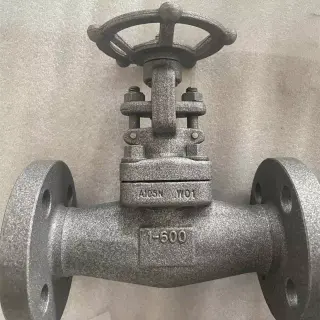

Product Name: Bolted Bonnet Forged Gate Valve

Design Standard: ASME B16.34, API 602

Body Material: ASTM A105

Size: Customized

Pressure: Class 800 LB, PN130

End Connection: SW

Operation: Manual

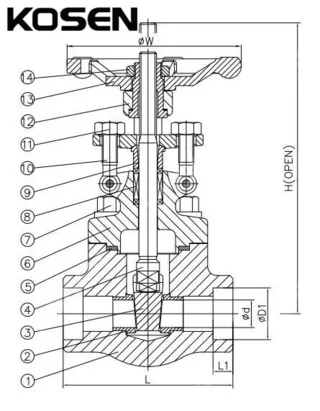

Forged Steel Gate Valves are designed and manufactured in compliance with International Standards such as API 602, ASME B16.34, and DIN 3202, ensuring reliability for high-pressure and high-temperature applications. These valves feature a compact yet robust design. An optional solid CoCr alloy wedge offers low friction and a long service life.

The packing rings are precompressed to 4000 psi, ensuring a high-integrity seal. For welded bonnet valves, the bonnet is threaded and torqued to a precise value, with the body-bonnet joint strength-welded for double protection against leakage. The fully guided wedge reduces wear on seating surfaces, enhancing durability.

Additional options include double packing, a leak-off connection, live-loading, and a packing blowout for easy removal of old packing.

Technical Specification

» Valve Structure: Forged Steel Gate Valve

» Size Range: 1/2-2 Inch (for Forged Items)

» Temperature Range: -29°C to 595°C

» Design Pressure: Class 150-2500 LB (PN10-PN420)

» Body Materials:

Carbon Steel, Alloy Steel, Stainless Steel, Duplex Steel, etc

ASTM A105N, A350 LF2, A182 F11, F22, F304, F304L, F316, F316L

» Trim Materials: 13%Cr, ASTM A182 F11, F22, SS 304, SS 304L, SS 316, SS 316L, and other specials

» End Connections: SW, FNPT, BW, RF, RTJ, Grooved

» Design and Manufacture: ASME B16.34, API 602

» Face to Face (End to End): ANSI B16.10

» Flanged Connection: ANSI B16.5

» Test and Inspection: API 598, API 6D

» Butt Welded Ends: ANSI B16.5

» Threaded Ends: ASME B1.20.1

» Socket-Weld Ends: ASME B16.11

» Medium: Water, Gas, Oil, etc.

Product Features

» OS&Y: Outside Stem and Yoke design for easy stem adjustment.

» Metal-sealed: Available with various API trims (#1, #5, #8, #10, etc.) for durable sealing.

» Optional Locking Device: Secure the valve in place with a locking mechanism or extend the stem for flexibility.

» Bonnet Options: Choose from bolted bonnet, welded bonnet, or pressure-sealed bonnet configurations.

» ISO 5211 Mounting: Direct mounting options for actuators to ISO 5211 standards.

» Port Options: Available in full bore or reduced port versions for flow control flexibility.